Thermoelectric compound stimulating type high-temperature smoke electrostatic processing device

A technology of electrostatic treatment and compound excitation, which is applied in the direction of electrostatic separation and power supply technology, can solve the problems of unstable electric field, corona breakdown, high power consumption, etc., and achieve the goal of reducing process difficulty, reducing production energy consumption, and high emission intensity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

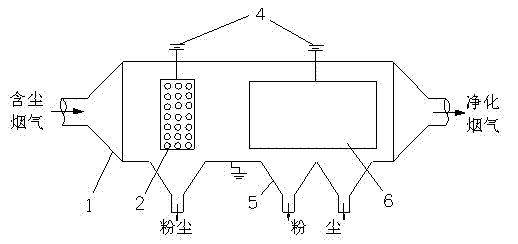

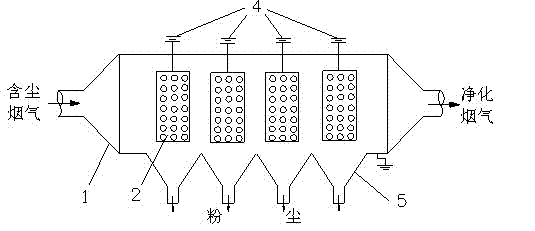

[0022] Below to figure 1 and image 3 As an example, the present invention is further described:

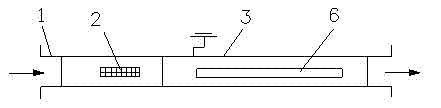

[0023] figure 1 It is a schematic diagram of a dual-zone self-excited electronic radiation high-temperature flue gas processor. As shown in the figure, it includes an emitter plate, a settling zone plate and a dust collection plate, forming a first A dust collection area forms a second dust collection area before the settling area plate and the dust collection plate, so it is called a double area in this field. figure 2 It is a single area.

[0024] After the flue gas with high temperature above 800°C containing dust and harmful gas enters the device, the high-level thermal energy of the high-temperature flue gas itself heats the special emitter plate 2 made of low work function material, causing the electrons inside the material of the emitter plate 2 to It is highly activated, and breaks through the surface barrier of the material and escapes as free electrons.

[0025] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com