A flexible LED strip light with an integrated light guide and its manufacturing method

A technology of LED strip lights and light guides, which is applied in the field of decoration and lighting, can solve the problems of low production efficiency, no waterproof effect, complicated process, etc., and achieve the goal of improving production efficiency, excellent waterproof effect, and good light guide effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

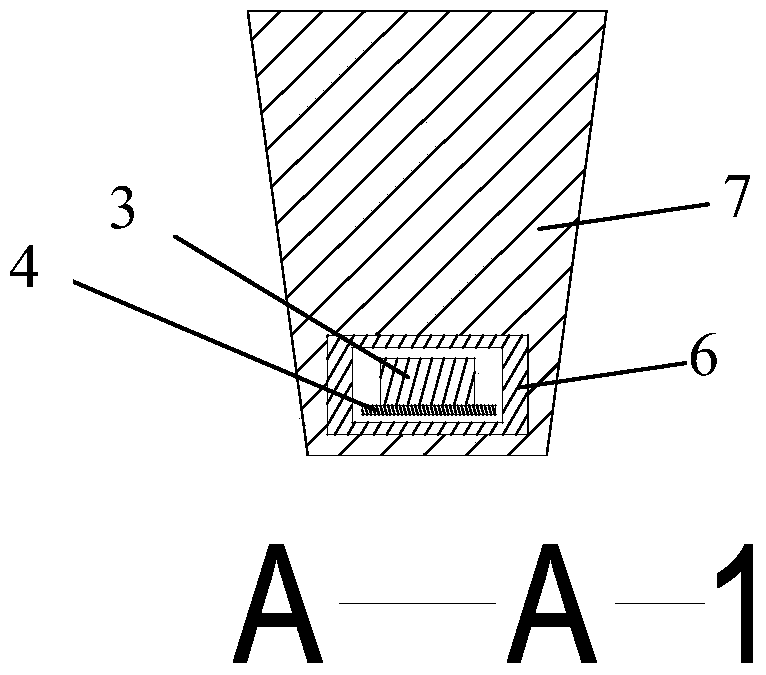

[0076] Figure 1 to Figure 4 Shown is a preferred embodiment 1 of the integrated structure light guide of the present invention, a flexible LED strip light with an integrated light guide, including a flexible strip-shaped LED light source 1 and a flexible strip-shaped LED light source 1 1 peripheral flexible cladding layer 2, the flexible strip-shaped LED light source 1 is a plurality of SMD LEDs 3 welded on the flexible strip-shaped circuit board 4 (such as Figure 4 As shown), the position of the cladding layer 2 corresponding to the LED 3 is provided with an inverted terrace-shaped light guide 5, and the light guide 5 and the cladding layer 2 are integrally structured.

[0077] refer to figure 2 As shown, the cladding layer 2 is a double-layer structure, that is, the cladding layer 2 includes an inner cladding layer 6 and an outer cladding layer 7, and the periphery of the inner cladding layer 6 is extruded from the outer cladding layer through an extrusion molding proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com