LED lamp bulb

A technology of LED light bulbs and LED chips, applied in the direction of lampshades, cooling/heating devices of lighting devices, lighting and heating equipment, etc., can solve problems such as interference between LED light-emitting substrates, difficulty in increasing heat dissipation, and reducing light output efficiency. Improve light extraction efficiency, eliminate spot interference, and improve lighting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] First, let's explain the two terms and their meanings used in the following description of the present application.

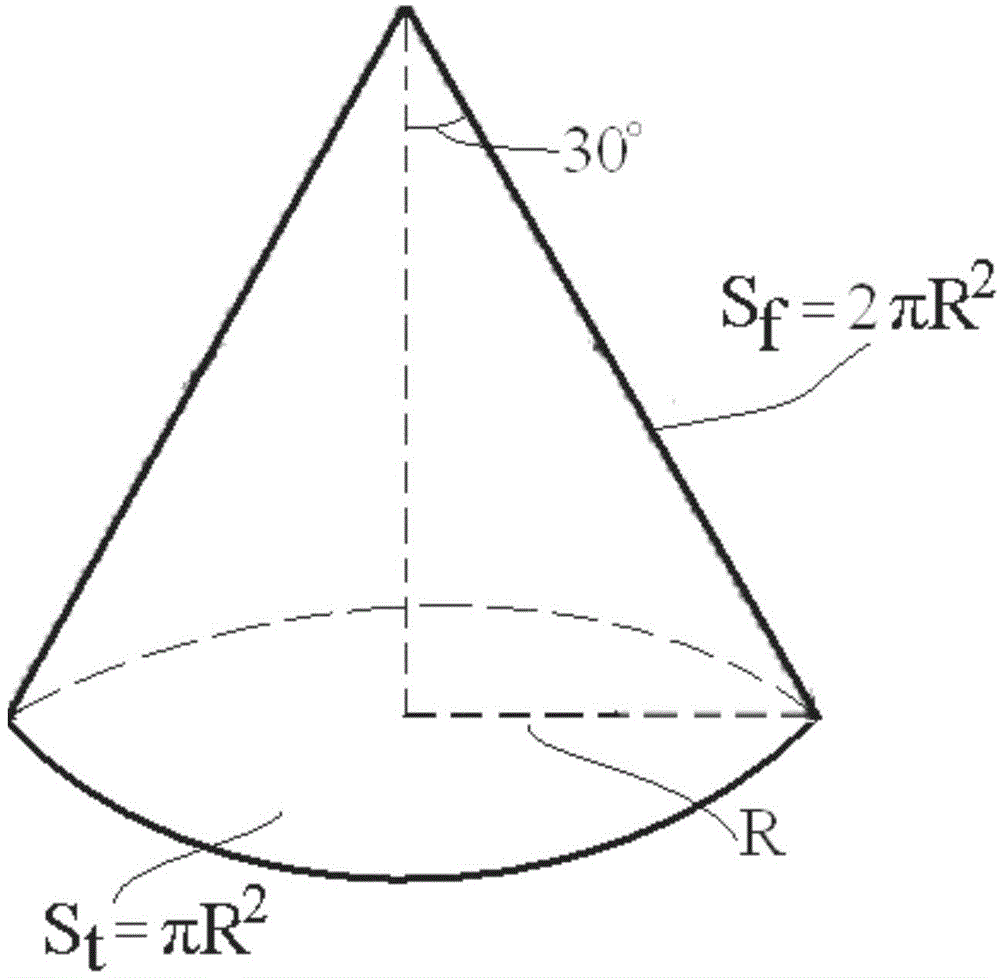

[0027] Light emitting area S f : Refers to the area of the surface from which light is emitted. For example in figure 1 The circular surface of the light-emitting LED chips is covered in an array, and its light-emitting area is πR 2 ;

[0028] Light area S t : The area of the optical channel bounded by the physical boundaries. Also refer to figure 1 The circular surface of the light-emitting LED chips is covered in an array. If the circular surface is considered to be a straight cylinder bottom, the light emitted from the bottom of the cylinder will pass through the cylinder opening along the cylinder wall. The area of the cylinder opening is the light transmission area S t .

[0029] According to the above description, it can be understood that the figure 1 In the case of the circular surface covered with light-emitting LED chips in an arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com