Drilling tool connection operation process method and tools

A technology of operating tools and process methods, which is applied in the fields of drilling and oil and gas drilling, can solve problems such as low operating efficiency and high labor intensity, and achieve the effects of improving operating efficiency, operating safety and reliability, and improving operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the present invention will now be described with reference to the accompanying drawings.

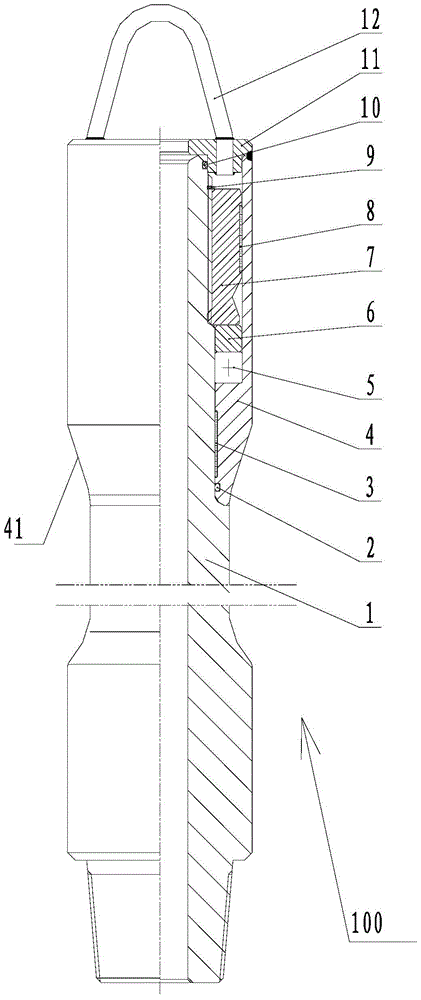

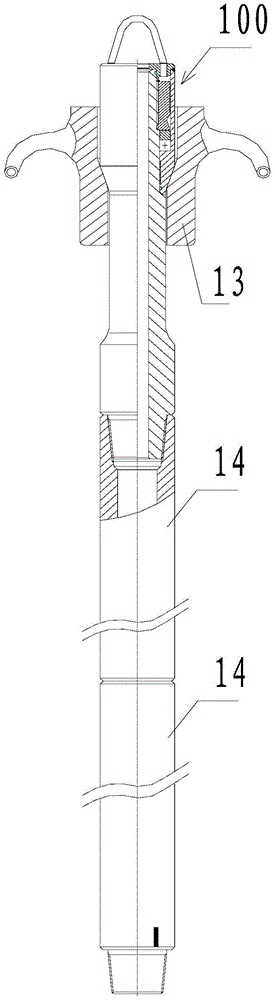

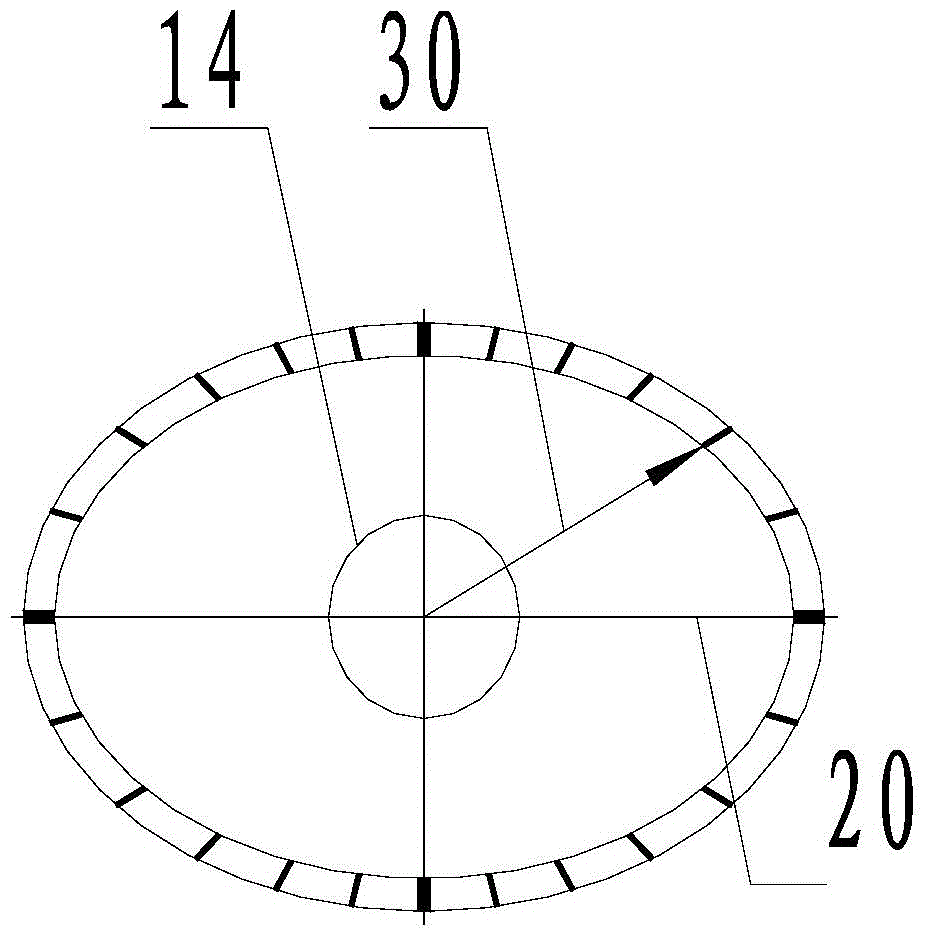

[0055] Such as figure 1 As shown, the drilling tool connection operation tool of the embodiment of the present invention includes: a rotating lifting sub-joint 100, and the rotating lifting sub-joint 100 includes:

[0056] Hollow mandrel 1, mandrel 1 is a hollow shaft body, the inner hole can pass drilling fluid, two ends are respectively processed with threads, the upper end thread is matched with the compression nut 7, and the lower end thread is matched with the drilling tool for the corresponding operation (such as a drill collar) connected;

[0057] An axial bearing 5 is sleeved on the top end of the mandrel 1, so that the mandrel 1 can rotate relative to the bearing sleeve 4 and can bear axial load;

[0058] Bearing sleeve 4, the inner wall of the bearing slee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com