Self-repairing concrete structure and manufacturing method thereof

A concrete structure, self-healing technology, applied in building construction, building maintenance, bridge maintenance, etc., can solve problems such as shortening service life, difficulty, structural brittle fracture, etc., to prevent expansion, ensure safety and durability, and high environmental protection. Sexual and economical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below through specific embodiments and related drawings.

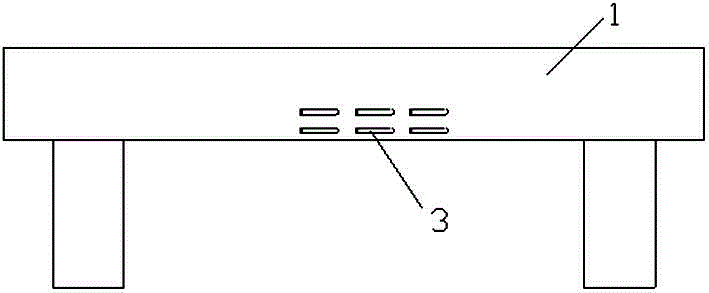

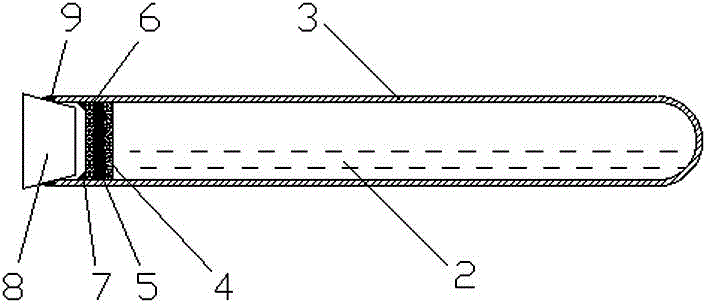

[0020] Such as Figure 1~2 Shown, a kind of self-repairing concrete structure comprises concrete component 1, is embedded with the glass tube 3 that a plurality of openings are sealed and is equipped with neoprene adhesive 2 in the tensile zone of described concrete component 1, and neoprene adhesive 2 has Good fluidity and bonding strength, the axial direction of the glass tube 3 is parallel to the tension direction of the tension zone where it is located.

[0021] When the tensile zone of the concrete member 1 cracks due to the tensile force, the glass tube 3 embedded in the concrete component 1 corresponding to the crack in the tensile zone will also break due to the axial tension, so that the neoprene adhesive 2 Seeping into the cracks of the concrete com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com