A double-connected automatic derusting machine for rails

A rust removal machine and rail technology, which is applied to tracks, track laying, track maintenance, etc., can solve the problems of low kinetic energy of wire brush wheels, inability to remove rust on the surface of rails, and poor rust removal effect, achieving strong flexibility and reducing kinetic energy loss. , the effect of reducing vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

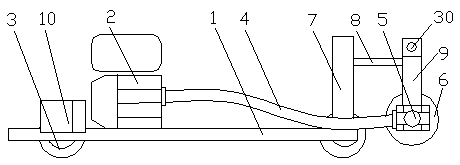

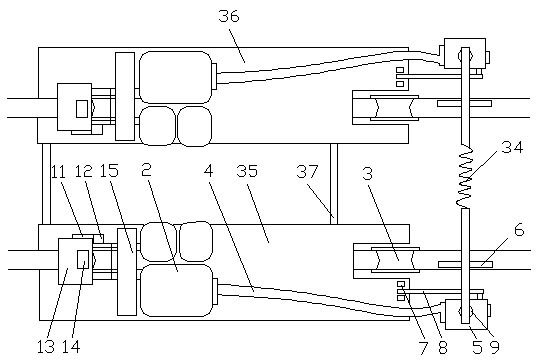

[0037] see figure 1 , a double-joint automatic descaling machine for steel rails, comprising a frame 1, an engine 2 fixed on the frame 1 and a wheel 3 connected below the frame 1, the engine 2 is two, and the two sides of the rail are distributed on each An engine 2 also includes two flexible shafts 4 and two steering gears 5, one end of the flexible shaft 4 is connected to the rotating shaft of the engine 2 through a coupling, and the other end of the flexible shaft 4 is connected to the input shaft of the steering gear 5 Connected, the output shaft of the diverter 5 is connected with a thousand-blade grinding wheel 6, the frame 1 is fixedly connected with two connecting pieces 7, and an upper and lower adjustment piece 9 is arranged above the diverter 5. The upper and lower adjustment pieces 9 is elastically connected with the steering gear 5, the connecting rod 8 of the connecting member 7 is connected with the upper and lower adjustment members 9, the upper and lower adjus...

Embodiment 2

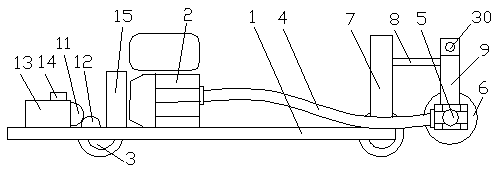

[0040] see figure 2 , a double-joint automatic descaling machine for steel rails, comprising a frame 1, an engine 2 fixed on the frame 1 and a wheel 3 connected below the frame 1, the engine 2 is two, and the two sides of the rail are distributed on each An engine 2 also includes two flexible shafts 4 and two steering gears 5, one end of the flexible shaft 4 is connected to the rotating shaft of the engine 2 through a coupling, and the other end of the flexible shaft 4 is connected to the input shaft of the steering gear 5 Connected, the output shaft of the diverter 5 is connected with a thousand-blade grinding wheel 6, the frame 1 is fixedly connected with two connecting pieces 7, and an upper and lower adjustment piece 9 is arranged above the diverter 5. The upper and lower adjustment pieces 9 is elastically connected with the steering gear 5, the connecting rod 8 of the connecting member 7 is connected with the upper and lower adjustment members 9, the upper and lower adju...

Embodiment 3

[0044] see figure 2 , a double-joint automatic descaling machine for steel rails, comprising a frame 1, an engine 2 fixed on the frame 1 and a wheel 3 connected below the frame 1, the engine 2 is two, and the two sides of the rail are distributed on each An engine 2 also includes two flexible shafts 4 and two steering gears 5, one end of the flexible shaft 4 is connected to the rotating shaft of the engine 2 through a coupling, and the other end of the flexible shaft 4 is connected to the input shaft of the steering gear 5 Connected, the output shaft of the diverter 5 is connected with a thousand-blade grinding wheel 6, the frame 1 is fixedly connected with two connecting pieces 7, and an upper and lower adjustment piece 9 is arranged above the diverter 5. The upper and lower adjustment pieces 9 is elastically connected with the steering gear 5, the connecting rod 8 of the connecting member 7 is connected with the upper and lower adjustment members 9, the upper and lower adju...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com