Composition used for cleaning after chemical mechanical polishing

A technology of chemical machinery and composition, applied in the direction of detergent composition, organic non-surface active detergent composition, non-surface active detergent composition, etc., can solve the problems of semiconductor quality reduction, equipment reliability reduction, corrosion, etc. Achieve the effect of excellent semiconductor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 to 3 and comparative example 1 to 7

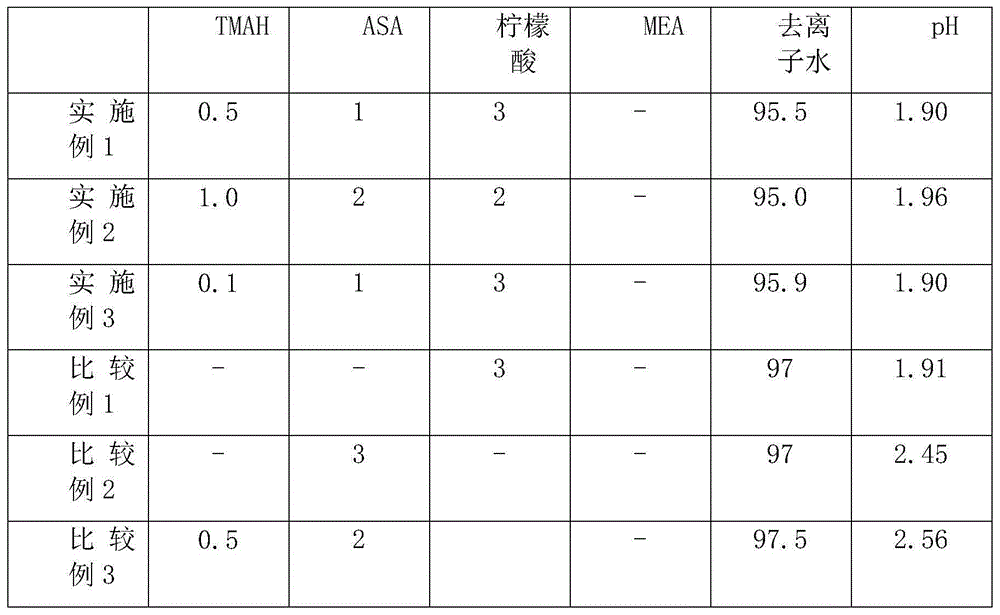

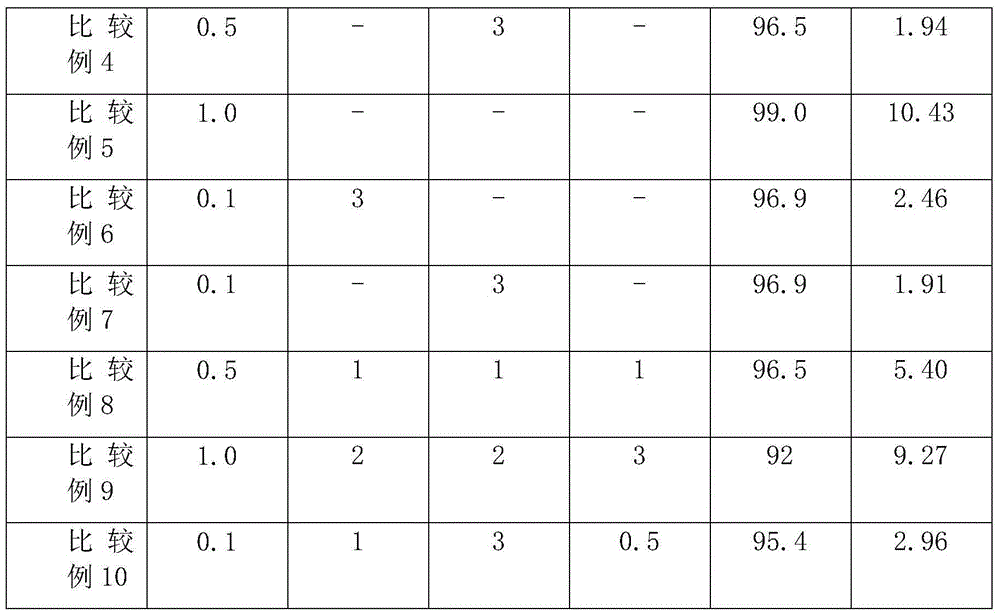

[0040] The composition of Table 1 below was prepared by mixing tetramethylammonium hydroxide (TMAH), ascorbic acid (ASA), citric acid, monoalcohol amine (MEA) as an amine compound other than TMAH, and deionized water. Compositions for cleaning after chemical mechanical polishing. (unit weight%)

[0041] [Table 1]

[0042]

[0043]

[0044]

[0045] Cleaning power evaluation test

[0046] After depositing 5.5KA thermal oxide layer (Thermal Oxide), 250A tantalum (Ta), and 1KA copper seed layer (Cu seed) on the silicon Si wafer, electroplating (Electro-Platating, EP) on 15KA copper (Cu), thus making A wafer with exposed metal components on the surface. The fabricated wafer is put into a CMP device and subjected to chemical mechanical polishing with a polishing slurry comprising Planar solution, hydrogen peroxide and distilled water.

[0047] After chemical mechanical polishing, put the chemical mechanically polished wafer into the On track device, and spray it with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com