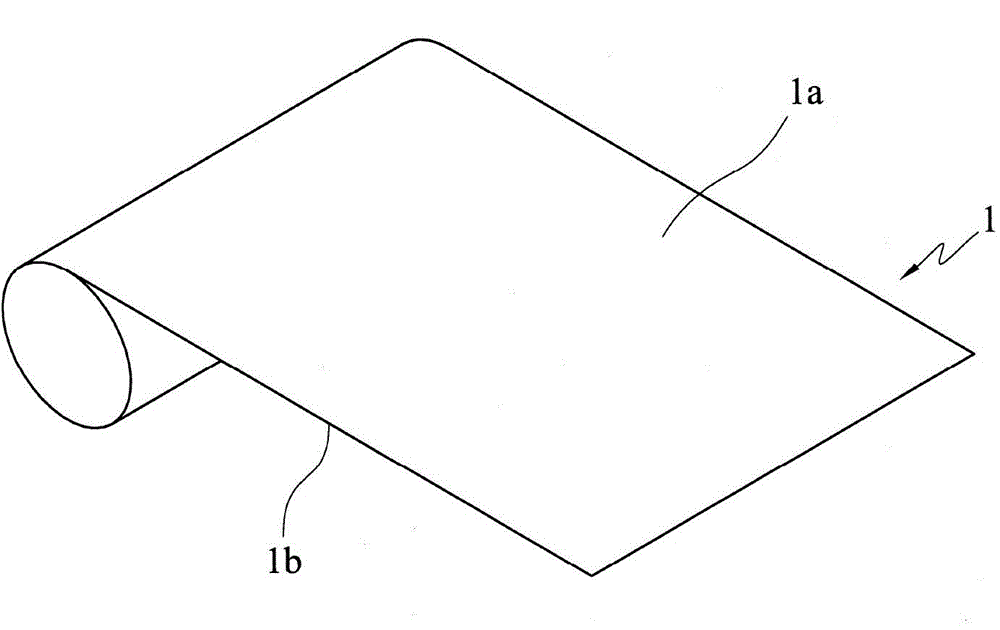

Polyethylene alcohol polymer film and production method

A technology of polymer film and polyvinyl alcohol, which is applied in the field of polyvinyl alcohol polymer film and its manufacture, can solve the problems of increasing the risk of film fracture, increasing the surface roughness of the air contact surface, and corrugation of the film surface, achieving Effects of increasing yield and yield, avoiding staining and warping, and improving heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

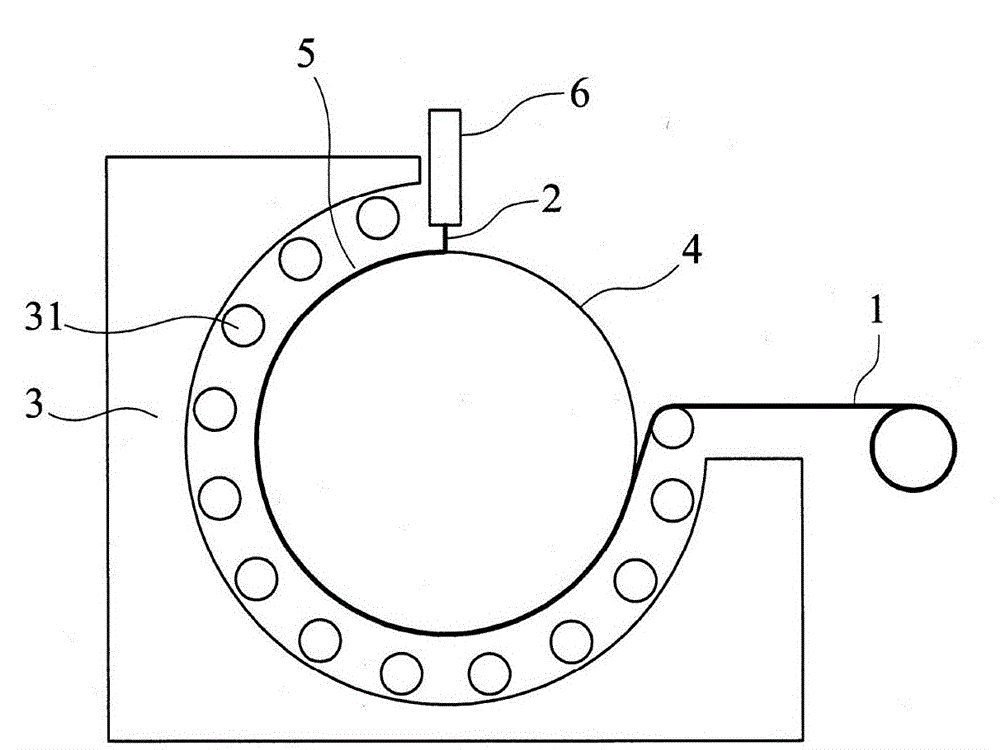

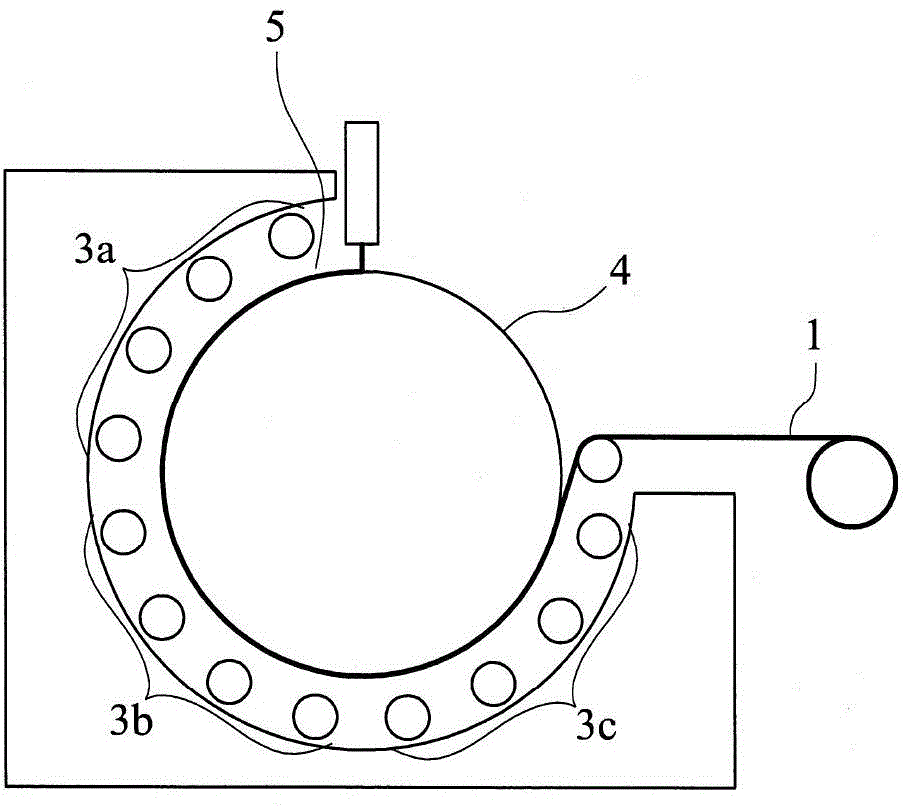

Embodiment 1

[0053] Add polyvinyl alcohol polymer resin (100 parts by weight) with a degree of polymerization of 2400 and a degree of alkalinity of 99.9% and 11 parts by weight of glycerin into water and heat up to 100 ° C, stir and dissolve to adjust the concentration to 25 parts by weight of polyvinyl alcohol Polymer aqueous solution (polyvinyl alcohol casting solution), after using a filter to filter the aqueous solution, and then using a gear pump and a T-die coater, the polyvinyl alcohol casting solution is cast to a 4-meter-wide heating space A casting drum, wherein the speed of the casting drum is 4 meters per minute (m / min), and the temperature is 95°C. The heating space is divided into a preheating zone, a heating zone and a buffer zone from the casting place of the polyvinyl alcohol casting solution to the peeling off of the polyvinyl alcohol polymer film, and each zone occupies a 90-degree zone of the casting drum. Using a wavelength conversion heater (NGK INSULATORS,LTD.) with ...

Embodiment 2

[0056] Production and evaluation of polyvinyl alcohol-based polymer films were carried out in the same manner as in Example 1, except that the speed of the casting drum was 6 m / min. Other analysis data are shown in Table 1 below.

Embodiment 3

[0058] Production and evaluation of polyvinyl alcohol-based polymer films were carried out in the same manner as in Example 1, except that the speed of the casting drum was 8 m / min. Other analysis data are shown in Table 1 below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com