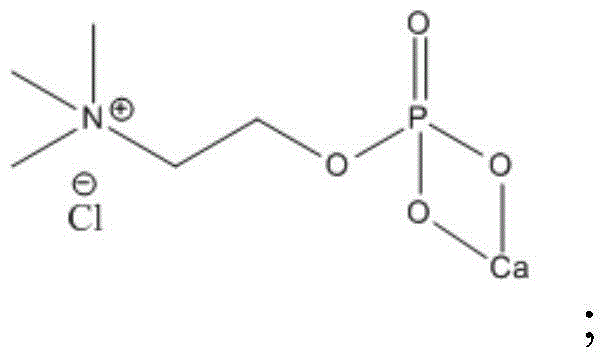

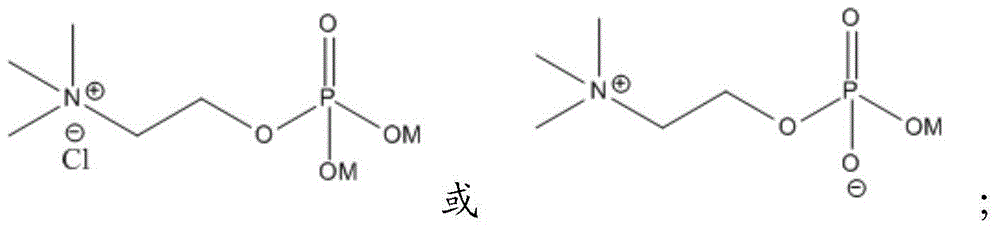

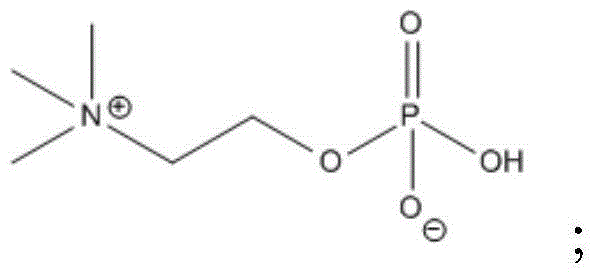

Industrial manufacturing method of glycerol phosphocholine

A technology of glycerophosphocholine and industrial manufacturing, applied in the direction of phosphorus organic compounds, can solve the problems of high cost, difficult purification, complicated reaction, etc., and achieve the effect of avoiding by-product problems and purification problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Add 330g of phosphorylcholine calcium salt (usually tetrahydrate) and 300ml of water into the reaction kettle, stir until it is clear, and add dropwise a 50% sodium carbonate solution made of 106g anhydrous sodium carbonate and water. Add dropwise at a rate of 10ml / min, after dropping, stirring at room temperature for 1 hour, according to the different solubility of sodium chloride, the sodium chloride in the reaction system is precipitated by salting out and then filtered.

[0046] The filtrate was passed through a sulfonic acid ion column and eluted with water several times until there was no product in HPLC.

[0047] The solvent was distilled under reduced pressure, concentrated to a volume of 300ml, 66g of (R)-chiral glycidol was added, stirred and refluxed for 2-6 hours, HPLC showed no raw materials, evaporated under reduced pressure to remove water, recrystallized in methanol to obtain 289g product. (HPLC>99.7%)

Embodiment 2

[0049] Add 330g of phosphorylcholine calcium salt (generally tetrahydrate) and 200ml of water into the reaction kettle, stir until it dissolves, and add dropwise a 35% potassium carbonate solution made of 138g of potassium carbonate and water to 5ml Add dropwise at a rate of 1 / min, after dropping, stir at room temperature for 0.5 hours, and pass through a silica gel column to remove potassium chloride and other insoluble inorganic salts.

[0050] The filtrate was passed through a sulfonic acid ion column, eluted with methanol several times until there was no product in HPLC, and evaporated under reduced pressure until there was no distillate.

[0051] 300ml of 1,2-dimethoxyethane was added to dissolve the above substances, 66g of (R)-chiral glycidol was added dropwise with stirring, and the reaction was refluxed for 8 hours. HPLC showed that there was no raw material, and the water was evaporated under reduced pressure to obtain 291g of product. (HPLC>99.5%)

Embodiment 3

[0053] Add 330g of phosphorylcholine calcium salt (generally tetrahydrate) and 500ml of water into the reaction kettle, stir until it is clear, and add dropwise a 65% sodium oxalate solution made up of 133g of sodium oxalate and water, with 2ml Add dropwise at a rate of 1 / min. After dropping, stir at room temperature until no new precipitation is generated. According to the solubility of sodium chloride, the sodium chloride in the reaction system is separated out by salting out and then filtered.

[0054] The filtrate was passed through a sulfonic acid ion column and eluted with 1,2-dimethoxyethane several times until there was no product in HPLC.

[0055] Concentrate to 400ml, add 66g of (R)-chiral glycidol dropwise with stirring, and react under reflux for 7 hours. HPLC shows that there is no raw material. The water is evaporated under reduced pressure to obtain 295g product. (HPLC>99.5%)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com