Active compliant control method and device of industrial robot

An industrial robot, active and flexible technology, applied in the direction of program control manipulators, manipulators, manufacturing tools, etc., can solve the problem of inability to contact force size control, and achieve the effect of intuitive force control, easy adjustment, and simple and convenient conversion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

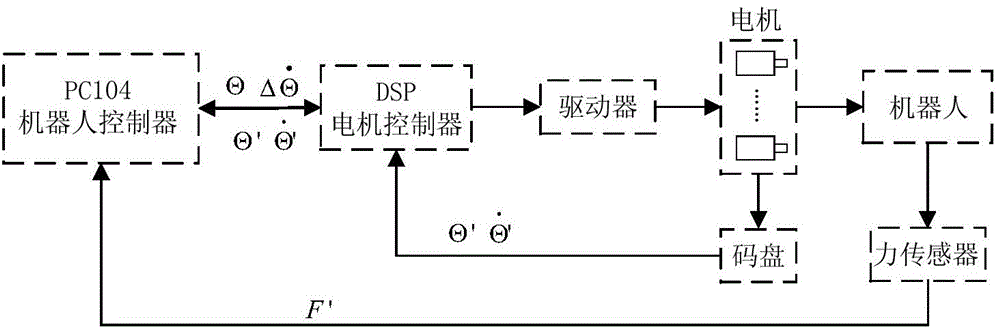

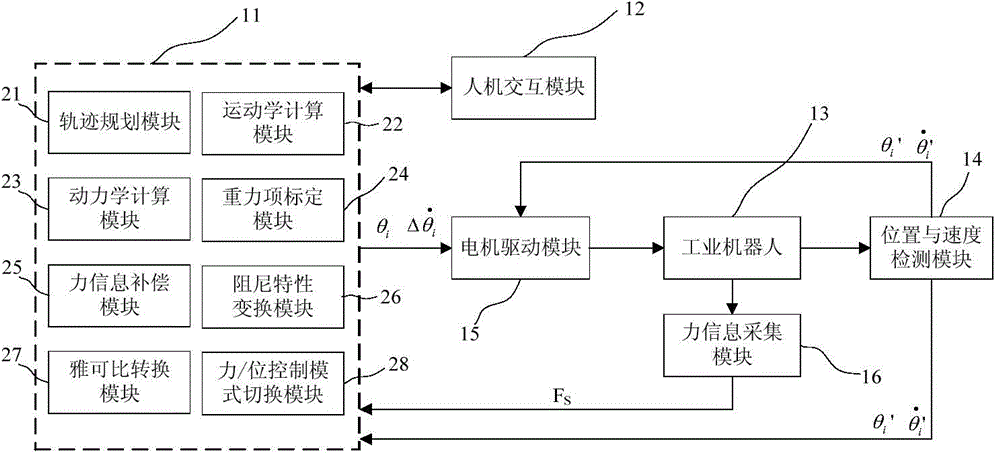

[0016] An active compliance control device for industrial robots of the present invention, such as figure 1 with 2 As shown, it includes a robot controller, a motor controller, a force sensing sensor, a code disc, several sets of motor drivers and servo motors. In this implementation, there are 6 sets of motor drivers and servo motors.

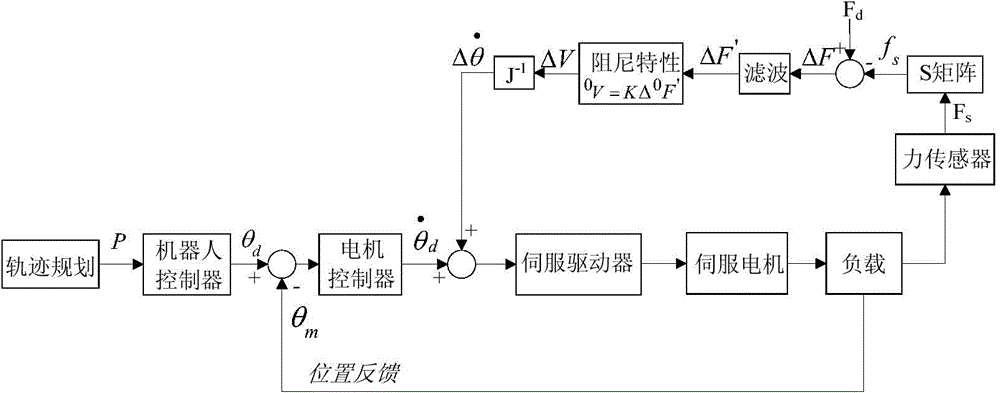

[0017] Among them, such as figure 2 As described, the robot controller 11 communicates with the motor drive module 15 using the standard CAN protocol, and transmits the target angle value Θ and the feedback angle value Θ'of each joint in the joint space, and the speed compensation value of the force control. The motor drive module 15 is composed of a motor controller and a motor driver; the force sensing sensor is used in the position and speed detection module 14 and the force information acquisition module 16.

[001...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com