Sludge disposal device with disposal-assisted structure

A mud discharge device and mud transportation technology, applied in cleaning methods and appliances, cleaning hollow objects, chemical instruments and methods, etc., can solve problems such as increased water injection pressure, difficult discharge, and decreased water absorption capacity of oil layers, and achieve rapid discharge efficiency , prolong the service life, and ensure the effect of using the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

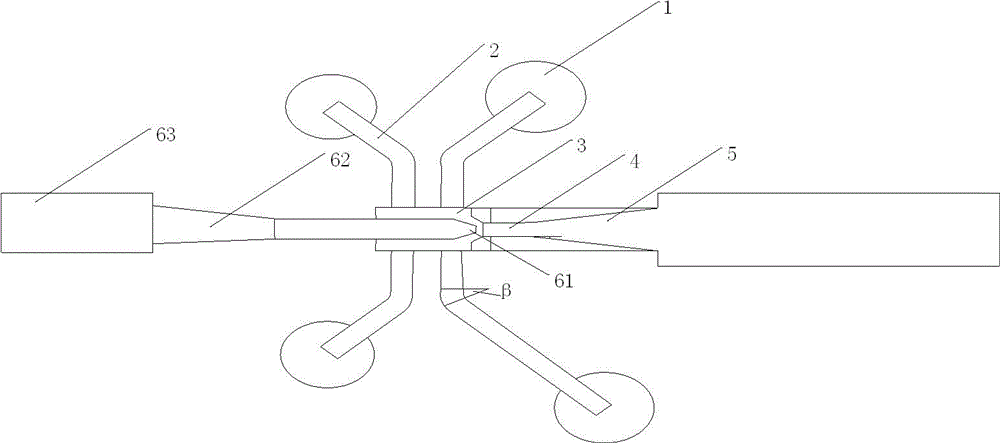

[0024] Such as figure 1 As shown, a mud discharge device with a drainage aid structure includes a mixing pipe 4, a diffusion pipe 5, a mud introduction chamber 3, a suction cup 1, a mud transportation pipe 2, and a drainage aid system, wherein the suction cup 1 and the mud transportation pipe 2 are both 4;

[0025] Each of the suction cups 1 and each of the sludge conveying pipes 2 are correspondingly connected to form a sludge conveying end, and the four sludge conveying ends are all connected through the sludge conveying pipe 2 and the sludge introduction chamber 3 and are evenly distributed in the sludge introduction. On both sides of the chamber 3, the mud transport pipe 2 is an elbow, and the curvature β is 25-35°;

[0026] One end of the mud introduction chamber 3 is connected to the mixing pipe 4, the mixing pipe 4 is connected to the diffuser pipe 5, and the other end of the mud introduction chamber 3 is connected to the drainage aid system, which includes a nozzle 61...

Embodiment 2

[0029] Similar to Example 1, the difference is:

[0030] The mixing tube 4 is a rectangular tube, and the diffuser tube 5 is trumpet-shaped. The design of the mixing tube 4 is conducive to the stable mixing of the dirt here so as not to reduce the removal effect, and the horn-shaped design of the diffusion tube 5 can facilitate the smooth and rapid discharge of the dirt.

[0031] The length ratio between the mixing tube 4 and the diffuser tube 5 is 1:5-8. Experiments show that the length ratio between the mixing tube 4 and the diffuser tube 5 has a certain influence on the discharge effect of the pollutants. Within the range of the length ratio of 1:5-8, the discharge efficiency is fast, and there is basically no deposition dead zone .

[0032] The mixing tube 4 and the diffuser tube 5 are connected by an arc. This smooth arc design is also convenient for the smooth discharge of dirt.

[0033] The diffuser 5 includes a trumpet-shaped front end and a cylindrical rear end, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com