High stability algal oil DHA microcapsule powder and preparation method thereof

A high-stability, microcapsule technology, applied in food science and other fields, can solve the problems of easy oxidation and fishy smell of products, and achieve the effects of avoiding cracking due to high temperature, uniform structure and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

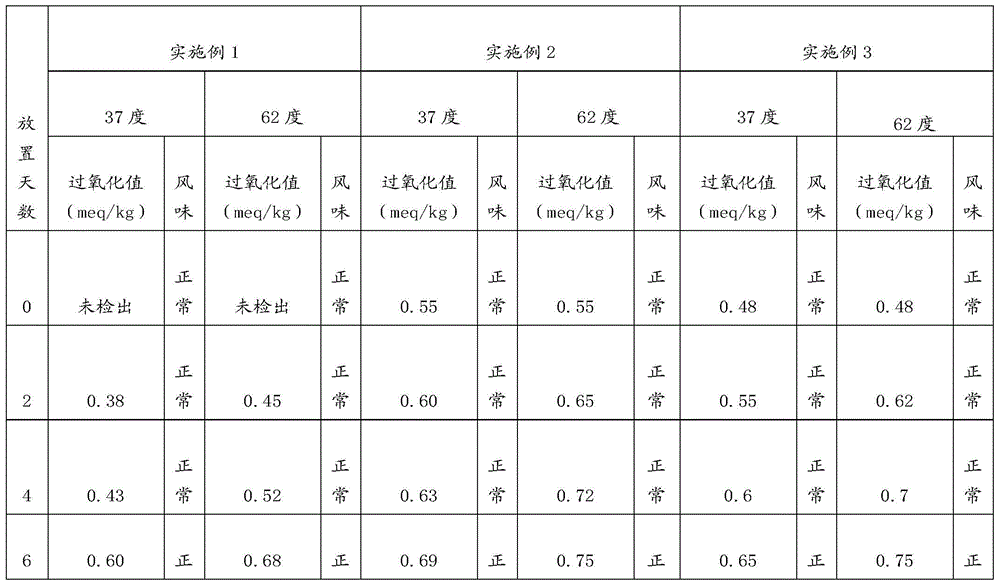

[0030] The present invention will be described in further detail below through specific implementation examples and in conjunction with the accompanying drawings.

[0031] Implementation case recipe:

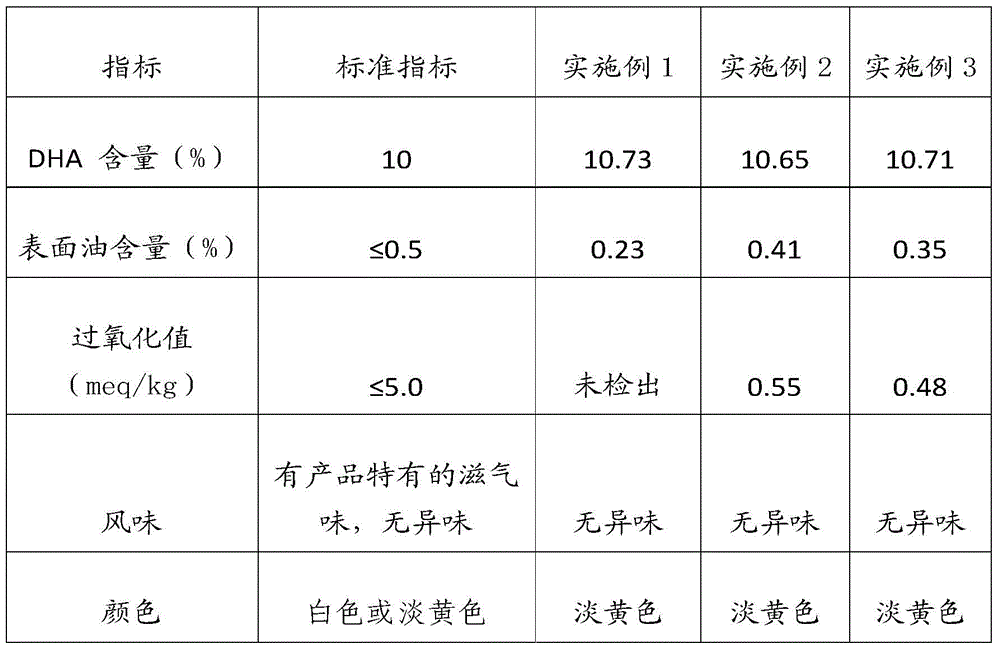

[0032] The wall material is composed of maltodextrin, modified starch and glucose powder, and its mass ratio is 60% to 80%: 10% to 30%: 6% to 10%, and the dosage accounts for 70% of the mass of algae oil DHA microcapsule powder- 90%, the combination of antioxidants is vitamin E, vitamin C palmitate and citric acid, and its mass ratio is 20% to 40%: 20% to 40%: 20% to 40%, and the dosage is 0.2% of algae oil DHA- 0.3%, the addition of DHA in the core material algae oil is 10%-30%.

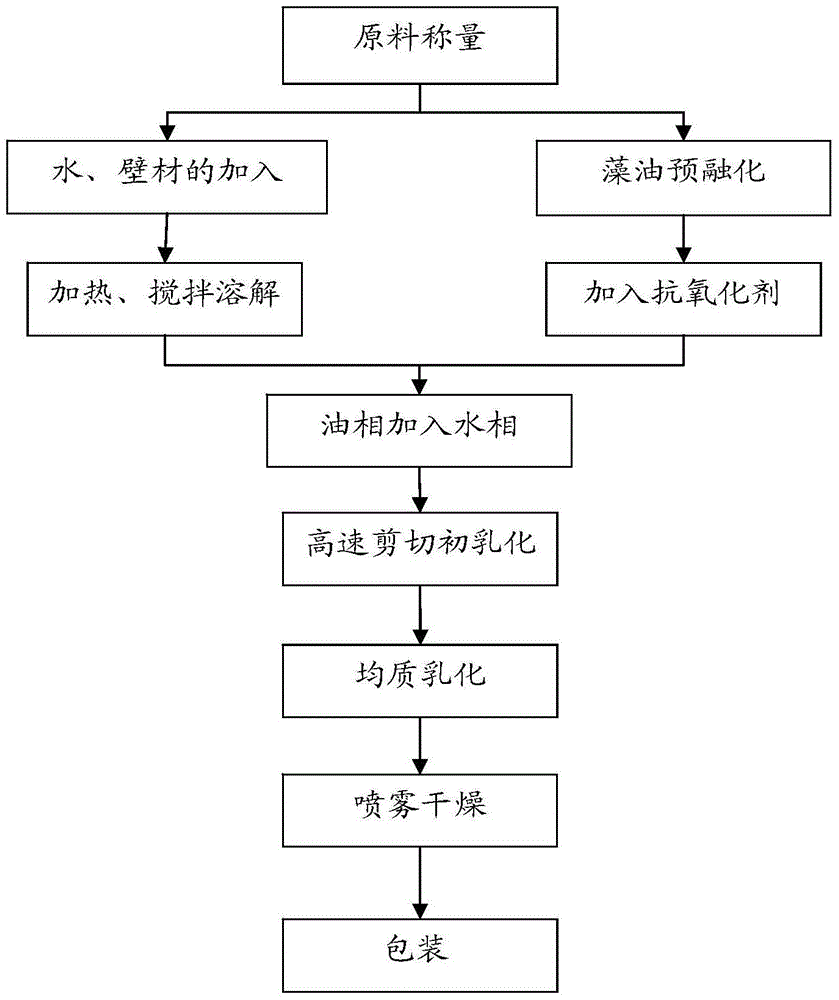

[0033] Implementation case process steps:

[0034] 1. Preparation of wall material solution

[0035] Target solid content of feed liquid: TS=45%

[0036] Calculation of water addition: target water addition = production batch (dry powder weight) / 45% - production batch (dry powder weight)

[0037]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com