A method for making rice noodles in a household rice noodle machine and a household rice noodle machine

A production method and technology of a rice noodle machine, which are applied in the application, food forming, food science and other directions, can solve the problems such as the inability to guarantee the curing temperature of rice noodle raw materials, the adverse effects of rice starch gelatinization and rice noodle molding, etc., so as to shorten the production cycle and improve the paste The effect of optimizing efficiency and optimizing elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0036] The first embodiment of the present invention is described with reference to the structure of the above-mentioned household rice noodle machine. A method for making rice noodles of a household rice noodle machine comprises the following steps:

[0037] Step 1, rice soaking: preferably early indica rice with amylose higher than 20% is used as raw material, soaked in water for 4h-12h, preferably 6-8h, so that the water content of the raw material reaches 25-30%;

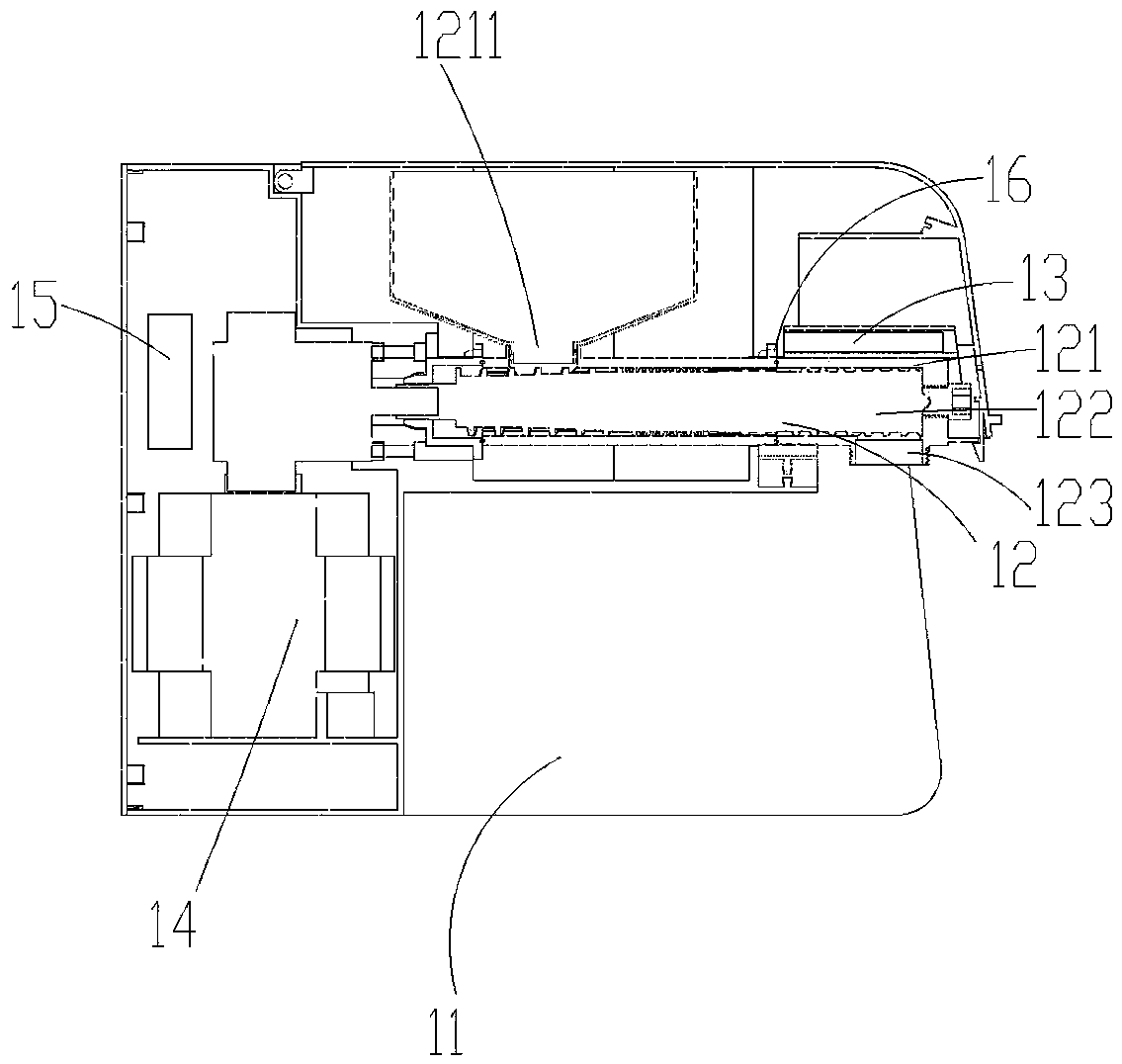

[0038] Step 2. Start the machine: Add rice raw materials and start the household rice noodle machine. First, the control system 15 detects whether the rice noodle machine is assembled properly.

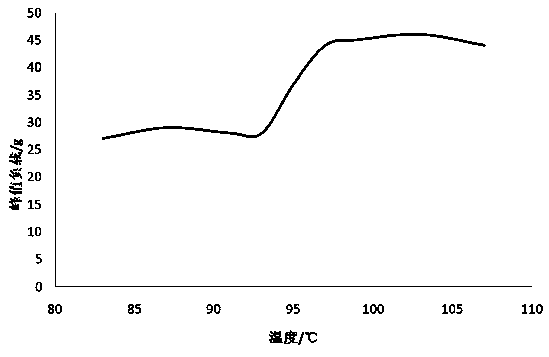

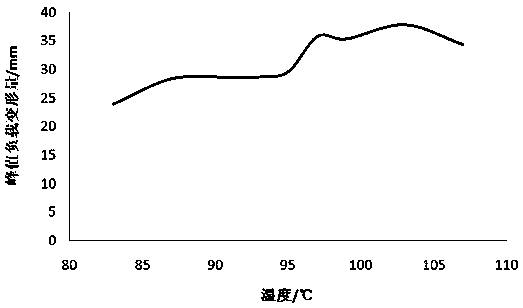

[0039] Step 3, a heating process: the control system 15 controls the heating device 13 to work, the heating device 13 heats the extrusion grinding chamber 121 so that the temperature of the extrusion grinding chamber 121 rises, and when the temperature sensor 16 detects that the temperature rises to T1, wherein The rang...

Embodiment approach 2

[0049] The second embodiment of the present invention differs from Embodiment 1 in that: the method for making rice noodles of the household rice noodle machine comprises the following steps:

[0050] Step 1, rice soaking: preferably early indica rice with amylose higher than 20% is used as raw material, soaked in water for 4h-12h, preferably 6-8h, so that the water content of the raw material reaches 25-30%;

[0051] Step 2, start-up: firstly, the control system 15 detects whether the rice noodle machine is assembled in place, if it is not assembled in place, an alarm will be given, and if it is assembled in place, it will be turned on normally;

[0052] Step 3, a heating process: the control system 15 controls the heating device 13 to work, the heating device 13 heats the extrusion grinding chamber 121 so that the temperature of the extrusion grinding chamber 121 rises, and when the temperature sensor 16 detects that the temperature rises to T1, wherein The range of T1 is 80...

Embodiment approach 3

[0060] The third embodiment of the present invention is different from the above-mentioned embodiment in that: the method for making rice noodles of the household rice noodle machine comprises the following steps:

[0061] Step 1, rice soaking: preferably early indica rice with amylose higher than 20% is used as raw material, soaked in water for 4h-12h, preferably 6-8h, so that the water content of the raw material reaches 25-30%;

[0062] Step 2, start-up: firstly, the control system 15 detects whether the rice noodle machine is assembled in place, if it is not assembled in place, an alarm will be given, and if it is assembled in place, it will be turned on normally;

[0063] Step 3, a heating process: the control system 15 controls the heating device 13 to work, the heating device 13 heats the extrusion grinding chamber 121 so that the temperature of the extrusion grinding chamber 121 rises, and when the temperature sensor 16 detects that the temperature rises to T1, wherein ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com