Post processing technology of mobile phone rear cover

A mobile phone back cover and post-processing technology, applied in the field of technology, can solve the problems of insufficient strength, many processes, easy to be damaged or scratched, etc., and achieve the effects of satisfying product quality, simplifying processing procedures, and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific embodiments.

[0025] The post-treatment process of the back cover of the mobile phone of the present invention is realized through the following steps:

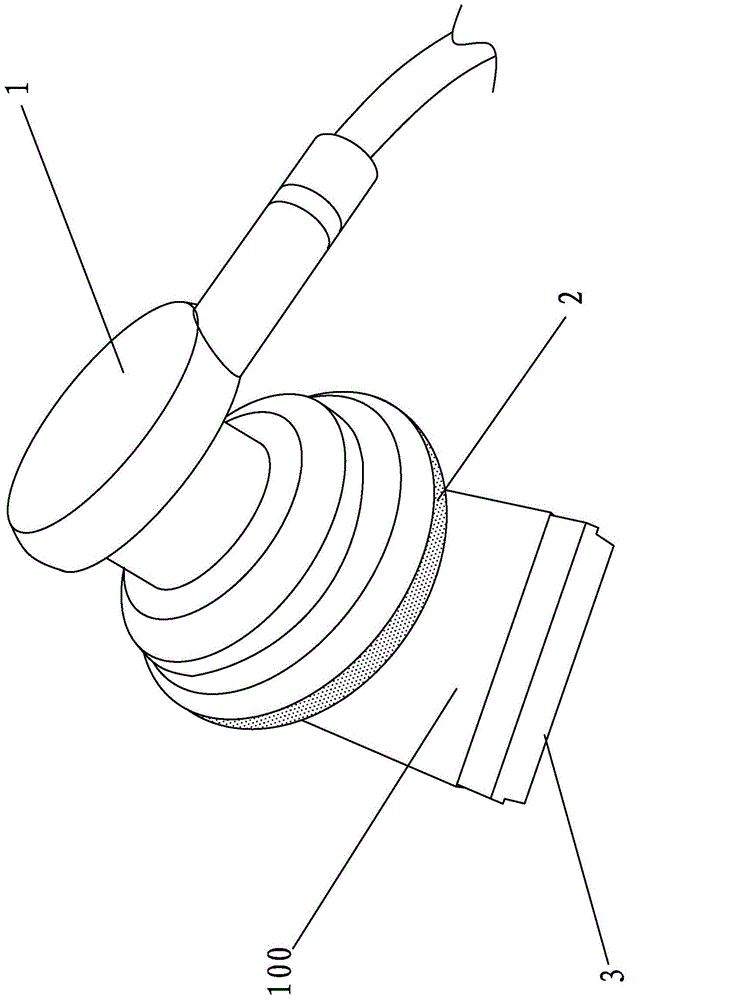

[0026] 1) Grinding rough opening: use the first hand-held grinder whose grinding disc is circular. 1 The front and both sides of the mobile phone back cover 100 to be processed are processed with grain patterns, and the first hand-held grinder is used for grinding. The sanding disc 11 of 1 is pasted with sandpaper 2 of model 600. This sandpaper 2 is in contact with the outer surface of the back cover 100 of the mobile phone. The speed of the first hand-held sander 1 is 9500-10500 rpm, and the first hand-held sander 1 The best speed is 10000rpm to get coarse parts;

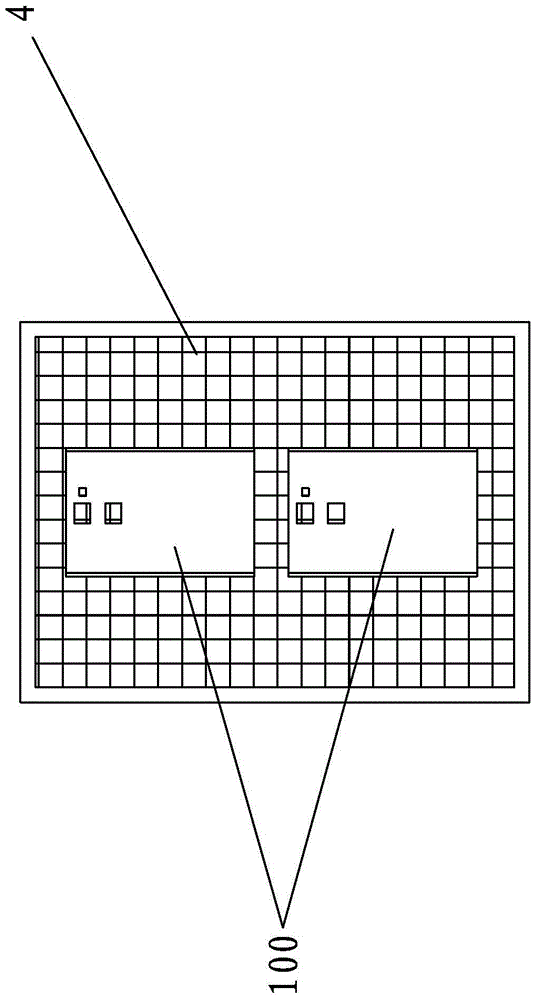

[0027] The specific operation is: figure 1 As shown, the mobile phone back cover 100 is buckled on a mobile phon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com