Bitumen-impregnated type composite steel wire rope for railway and production method thereof

A production method and asphalt-impregnated technology, which is applied in the asphalt-impregnated composite steel wire rope used in railways and its production field, can solve the problems that the composite steel wire rope cannot meet the design requirements of high-speed railways, and can not meet the requirements, so as to ensure work efficiency and work safety , high tensile strength and high filling factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

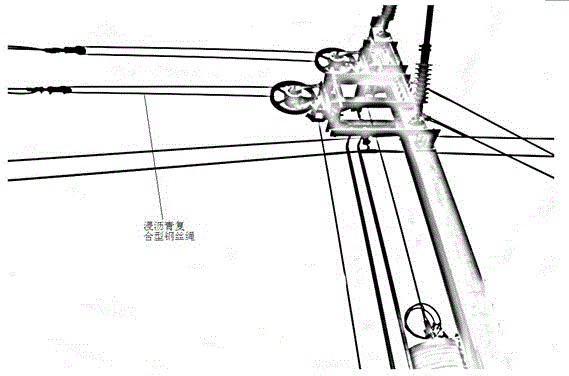

Image

Examples

Embodiment 1

[0035] Another aspect of the present invention provides a production method of asphalt-impregnated composite steel wire rope for railway, the structure of the asphalt-impregnated composite steel wire rope for railway is 12×26WS+12×7+1×36SFi, and the tensile strength of single-strand structure is greater than Equal to 2300Mpa, the knotting tension is greater than or equal to 55%, the number of torsion resistance is greater than or equal to 21, the tension of the inner strands is greater than or equal to 2300KN, and the tension of the outer strands is greater than or equal to 6000KN, which includes the following steps,

[0036] Step 1. For the wire rod, use SWRH72A with a diameter of 5.5 mm.

[0037] Step 2. Rough drawing. Use a straight wire drawing machine model 11 / 560 to draw a 5.5 mm diameter SWRH72A wire into a 2.0 mm SWRH72A. The drawing process is 5.5-4.9-4.4-4.0-3.7-3.4- 3.1-2.8-2.5-2.2-2.0.

[0038] Step 3, heat treatment, choose a gas-fired type 32 electric heating fu...

Embodiment 2

[0048] Another aspect of the present invention provides a production method of asphalt-impregnated composite steel wire rope for railway, the structure of the asphalt-impregnated composite steel wire rope for railway is 12×26WS+12×7+1×36SFi, and the tensile strength of single-strand structure is greater than Equal to 2300Mpa, the knotting tension is greater than or equal to 55%, the number of torsion resistance is greater than or equal to 21, the tension of the inner strands is greater than or equal to 2300KN, and the tension of the outer strands is greater than or equal to 6000KN, which includes the following steps,

[0049] Step 1. For the wire rod, use SWRH72A with a diameter of 5.5 mm.

[0050] Step 2. Rough drawing. Use a straight wire drawing machine model 11 / 560 to draw a 5.5 mm diameter SWRH72A wire into a 2.0 mm SWRH72A. The drawing process is 5.5-4.9-4.4-4.0-3.7-3.4- 3.1-2.8-2.5-2.2-2.0.

[0051] Step 3, heat treatment, choose a gas-fired type 32 electric heating fu...

Embodiment 3

[0062] Another aspect of the present invention provides a production method of asphalt-impregnated composite steel wire rope for railway, the structure of the asphalt-impregnated composite steel wire rope for railway is 12×26WS+12×7+1×36SFi, and the tensile strength of single-strand structure is greater than Equal to 2300Mpa, the knotting tension is greater than or equal to 55%, the number of torsion resistance is greater than or equal to 21, the tension of the inner strands is greater than or equal to 2300KN, and the tension of the outer strands is greater than or equal to 6000KN, which includes the following steps,

[0063] Step 1. For the wire rod, use SWRH72A with a diameter of 5.5 mm.

[0064] Step 2. Rough drawing. Use a straight wire drawing machine model 11 / 560 to draw a 5.5 mm diameter SWRH72A wire into a 2.0 mm SWRH72A. The drawing process is 5.5-4.9-4.4-4.0-3.7-3.4- 3.1-2.8-2.5-2.2-2.0.

[0065] Step 3, heat treatment, choose a gas-fired type 32 electric heating fu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com