High-count combed camel hair woven yarn

A camel hair and combing technology, which is applied in the field of high-count combed camel hair woven yarns, can solve the problem of low added value of products, achieve considerable economic and social benefits, reduce production costs, and reduce the amount of synthetic cashmere used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Raw material: 40mm camel hair fiber 50%, 75mm vinylon strip 50%

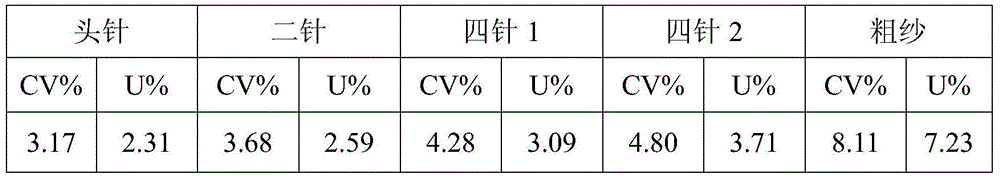

[0025] (1) strip

[0026] The combed camel hair goes through the kneading process to make the raw material oily and moisture regain meet the requirements of the machine. The formula adopted is 1.0% of the total input amount of environmentally friendly and crude oil CTA-1880C and 0.8% of environmentally friendly antistatic agent FK-305. The final raw materials are stored for 24 hours to keep in good health, so that the oil and water can fully penetrate evenly before being used on the carding machine; during the process of carding and needle combing, the speed ratio of the carding machine and the roller gauge of the needle card machine should be reasonably adjusted, and the appropriate draft ratio should be configured to reduce Fiber damage (small draft, small gauge, low speed). The technical parameters of each process of combed camel hair sliver making are shown in Table 1, and the indicators of combed ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com