Wine red superfine denier yarn bamboo fiber and special-shaped colored polyester fiber blending product and spinning method thereof

A technology of colored polyester and fiber blending, applied in textiles, papermaking, yarn, etc., can solve the problems of low yarn strength, fiber damage, low strength of colored fibers, etc., achieve improved cloth surface effect, improved breaking strength, and reduced broken ends Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

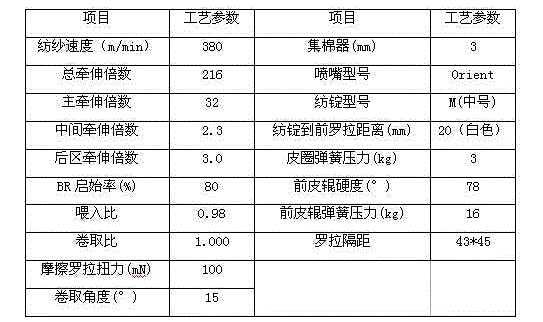

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the examples. Since the following descriptions are only specific embodiments of the present invention, the protection of the present invention is not limited thereto, and any changes or substitutions that can be conceived by those skilled in the art are included in the present invention. within the scope of protection of the invention.

[0029] The main technical process routes are as follows:

[0030] The main technical process of blending wine red ultra-fine denier bamboo fiber and special-shaped colored polyester is as follows:

[0031] FA002 Type Cotton Premixer→Bale Forming Machine→FA002 Type Cotton Grabber→A006B Type Cotton Blender→FA106 Type Cotton Opener→A092AST Type Cotton Feeder→A076F Type Roller→FA201B Type Carding Machine→FA306A Type Combined Frame frame (second pass)→TD8 autoleveler draw frame→Vortex870 eddy current spinning frame

[0032] Wine red ultra-fine denier bamboo fiber has...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com