An energy-saving and environment-friendly electrochemical corrosion expansion method for electronic aluminum foil

An electronic aluminum foil, energy saving and environmental protection technology, applied in the direction of electrolytic capacitors, capacitors, circuits, etc., can solve the problems of increasing the cost of chemical drugs, difficult to control the stability of alkali cleaning process, affecting the mechanical properties of aluminum foil, etc. Reasonable, highly uniform, good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

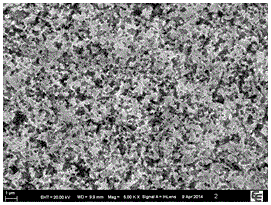

Image

Examples

Embodiment 1

[0029] Embodiment 1 Implement the present invention according to the following steps:

[0030] (1) Surface treatment: use 2.0 mol / L HCl and 0.1 mol / L AlCl 3 Mix the solution and treat the surface of the electronic aluminum foil (light foil) at 60°C for 80 seconds;

[0031] (2) Nanocloth holes: place the aluminum foil obtained in step (1) under a sinusoidal waveform with a current density of 0.35~0.55A / cm², a frequency of 25-35Hz, a temperature of 35~45°C, and 2 mol / L of HCl , 0.1 mol / L AlCl 3 , 0~1 mol / LH 2 SO 4 , 0~1 mol / L H 3 PO 4 , 0~1 mol / L HNO 3 Take it out after 20 seconds in the mixed solution (electrocorrosive solution);

[0032] (3) Surface cleaning: put the aluminum foil obtained in step (2) into pure water at 20~35°C for 40 seconds and take it out;

[0033] (4) Repeat hole layout: Repeat step (2) and step (3) 1 to 3 times, and the specific process parameters can be adjusted appropriately;

[0034] (5) Deep electric corrosion: place the aluminum foil obtaine...

Embodiment 2

[0039] Embodiment 2 Implement the present invention according to the following steps:

[0040] (1) Surface treatment: use 2.0 mol / L HCl and 0.1 mol / L AlCl 3 Mix the solution and treat the surface of the electronic aluminum foil (light foil) at 60°C for 80 seconds;

[0041] (2) Nanocloth holes: place the aluminum foil obtained in step (1) under a specific waveform with a current density of 0.35~0.55A / cm², a frequency of 25-35Hz, a temperature of 35~45°C, and 2 mol / L of HCl , 0.1 mol / L AlCl 3 , 0~1 mol / LH 2 SO 4 , 0~1 mol / L H 3 PO 4 , 0~1 mol / L HNO 3 Take it out after 20 seconds in the mixed solution (electrocorrosive solution);

[0042] (3) Surface cleaning: put the aluminum foil obtained in step (2) into pure water at 20~35°C for 40 seconds and take it out;

[0043] (4) Repeat hole layout: Repeat step (2) and step (3) 1 to 3 times, and the specific process parameters can be adjusted appropriately;

[0044] (5) Deep electric corrosion: put the aluminum foil processed i...

Embodiment 3

[0049] Embodiment 3 Implement the present invention according to the following steps:

[0050] (1) Surface treatment: use 2.0 mol / L HCl and 0.3 mol / L AlCl 3 Mix the solution and treat the surface of the electronic aluminum foil (light foil) at 60°C for 80 seconds;

[0051] (2) Nanocloth holes: place the aluminum foil obtained in step (1) under a specific waveform with a current density of 0.35~0.55A / cm², a frequency of 25-35Hz, a temperature of 35~45°C, and 2 mol / L of HCl , 0.3 mol / L AlCl 3 , 0~1 mol / LH 2 SO 4 , 0~1 mol / L H 3 PO 4 , 0~1 mol / L HNO 3 Take it out after 20 seconds in the mixed solution (electrocorrosive solution);

[0052] (3) Surface cleaning: put the aluminum foil obtained in step (2) into pure water at 20~35°C for 40 seconds and take it out;

[0053] (4) Repeat hole layout: Repeat step (2) and step (3) 1 to 3 times, and the specific process parameters can be adjusted appropriately;

[0054] (5) Deep electric corrosion: put the aluminum foil processed i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com