Low energy consumption hydrocracking method for producing high-quality chemical industry raw material

A technology of hydrocracking and chemical raw materials, which is applied in the fields of hydrotreating process, hydrocarbon oil cracking, petroleum industry, etc. It can solve the problems of unreasonable use of hydrocracking reaction heat, complicated process flow, and API degree drop, and achieve reduction Project investment and operating energy consumption, improving product quality, and maintaining selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

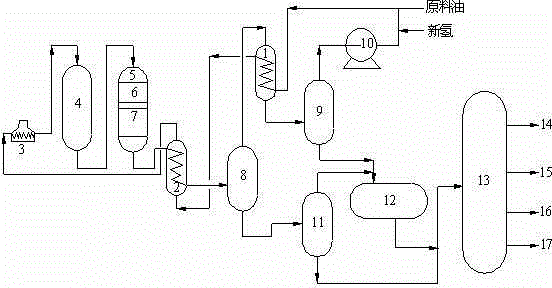

[0031] use figure 1 process shown. Using VGO as the raw material oil, the catalyst system of FF-46 hydrocracking pretreatment catalyst and hydrocracking catalyst Ⅰ / hydrocracking catalyst Ⅱ in different volume ratios was selected. Catalyst Ⅰ and catalyst Ⅱ are both supported by amorphous silica-alumina and modified Y molecular sieve. The volume ratios of hydrocracking catalyst I / hydrocracking catalyst II in Examples 1-3 are 2:1, 1:1 and 1:2, respectively.

[0032] At a total reaction pressure of 15.7MPa, the volume ratio of hydrogen to oil in the refining section and the cracking section is 900:1 and 1200:1 respectively, and the volume space velocity of the refining section and the cracking section are 1.0h -1 and 1.5h -1 , control the nitrogen content of refined oil to 5-8 μg×g -1 , a process test with a conversion rate of about 75wt% at >350°C was carried out, in which the temperature difference between the beds of hydrocracking catalyst I and hydrocracking catalyst II wa...

Embodiment 4

[0046] According to the complete set of hydrogenation technology of the present invention, newly build a set of 2 million tons / year hydrocracking unit, carry out economic calculation and can obtain following conclusion:

[0047] (1) Specific comparison results with conventional hydrocracking unit project investment:

[0048] 1. The investment of high-pressure heat exchanger was reduced by 4.9 million yuan;

[0049] 2. The investment in reaction feed heating furnace was reduced by 9.24 million yuan;

[0050] 3. The investment of thermal high-separation air-air cooler was reduced by 8.2 million yuan;

[0051] 4. The investment in circulating hydrogen compressor is reduced by 500,000 yuan;

[0052] The total investment in installation projects decreased by 22.84 million yuan, a decrease of 4.56%.

[0053] (2) Compared with the fuel consumption of conventional hydrocracking units, the results are as follows:

[0054] 1. The fuel consumption of the reaction feed heating furnace...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com