Oil-in-water drilling fluid with vegetable oil as internal phase and preparation method of oil-in-water drilling fluid

A technology of oil-in-water drilling fluid and vegetable oil, which is applied in the field of petroleum exploration, can solve the problems of high biotoxicity and difficult biodegradation of mineral oil, and achieve the effects of ultra-low treatment cost, high permeability recovery value, and less dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

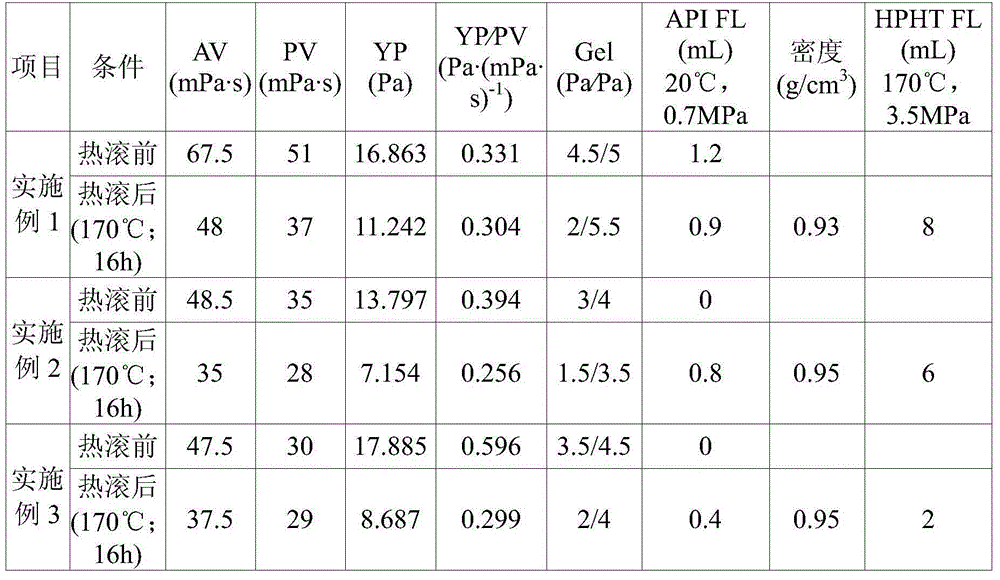

Embodiment 1

[0034] This embodiment provides a method for preparing oil-in-water drilling fluid with vegetable oil as the internal phase, and the specific steps are as follows:

[0035] The oil-water volume ratio is 60 / 40, first measure 240mL coconut oil, add 12g sodium dodecylbenzenesulfonate, 7.2g alkanolamide (RCON(CH 2 CH 2 Oh) 2 , where R is C 12 Alkyl), 4g of oxidized pitch, stirred at a high speed of 11000r / min for 30 minutes to obtain an oil phase.

[0036] Measure 160mL of clear water, add 6g carboxymethyl starch, 1g NaOH, 0.4g xanthan gum respectively, stir at 11000r / min at high speed for 20 minutes, then add 16g sulfomethyl phenolic resin in turn, and stir at 11000r / min at high speed After 20 minutes, an aqueous phase was obtained.

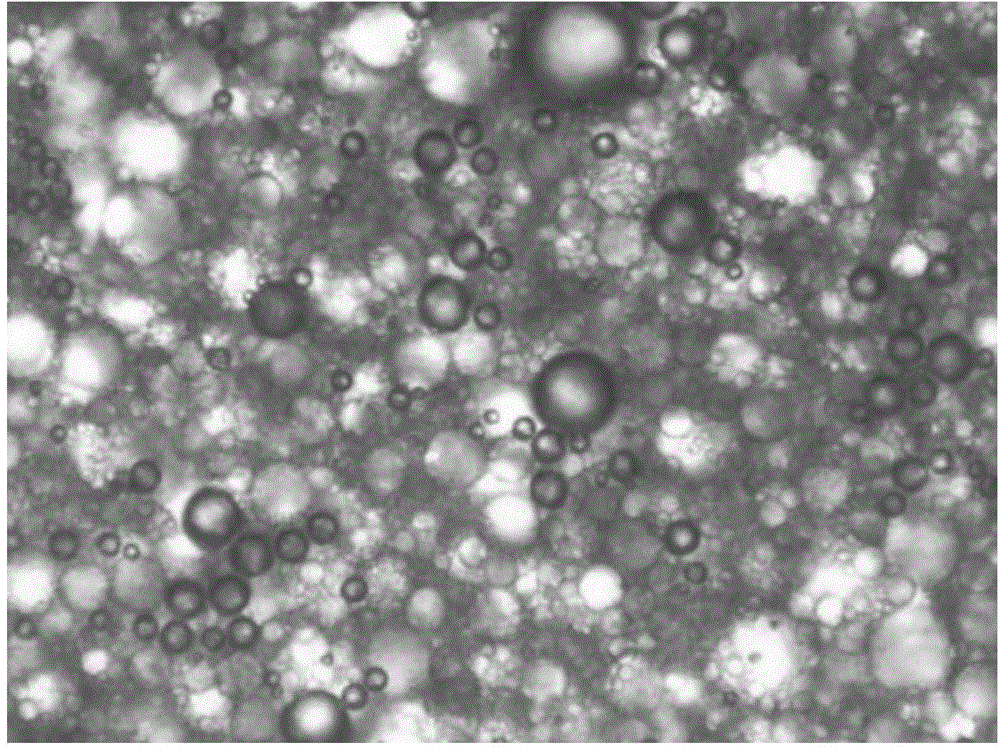

[0037] Finally, slowly add the oil phase to the water phase while stirring at high speed, and continue to stir at a high speed of 11000r / min for 30 minutes, so that the emulsion is completely emulsified, the formed interface film is stable, and ...

Embodiment 2

[0039] This embodiment provides a method for preparing oil-in-water drilling fluid with vegetable oil as the internal phase, and the specific steps are as follows:

[0040] The oil-water volume ratio is 50 / 50, first measure 200mL soybean oil, add 10g tween-60 (Shanghai Hushi Chemical Co., Ltd.), 6gOP-4 (Tianjin Xiongguan Technology Development Co., Ltd.), 6g natural asphalt in turn, at 11000r / Stir at high speed for 30 minutes under min to obtain an oil phase.

[0041] Measure 200mL of clear water, add 5g of hydroxyethyl starch, 1g of NaOH, and 0.6g of bentonite respectively, stir at a high speed of 11000r / min for 20 minutes, then add 14g of sulfonated lignite resin in turn, and stir at a high speed of 11000r / min for 20 minutes, An aqueous phase is obtained.

[0042] Finally, slowly add the oil phase to the water phase while stirring at high speed, and continue to stir at a high speed of 11000r / min for 30 minutes, so that the emulsion is completely emulsified, the formed inte...

Embodiment 3

[0044] This embodiment provides a method for preparing oil-in-water drilling fluid with vegetable oil as the internal phase, and the specific steps are as follows:

[0045] The volume ratio of oil to water is 40 / 60, first measure 160mL rapeseed oil, then add 8g cetyltrimethylammonium bromide, 4.8g oleic acid diethanolamide, 14g humic acid amide in sequence, at 11000r / min at high speed Stir for 25 minutes to obtain an oily phase.

[0046] Then measure 240mL of clear water, add 4g hydroxyethyl cellulose, 1.2g NaOH, 0.4g xanthan gum respectively, stir at a high speed of 11000r / min for 20 minutes, then add 6g of sulfonated asphalt in turn, and stir at a high speed of 11000r / min Stir for 20 minutes to obtain an aqueous phase.

[0047] Finally, slowly add the oil phase to the water phase while stirring at high speed, and continue to stir at a high speed of 11000r / min for 30 minutes, so that the emulsion is completely emulsified, the formed interface film is stable, and the emulsion...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com