Graphene oxide-polyurethane compound foam as well as preparation method and application thereof

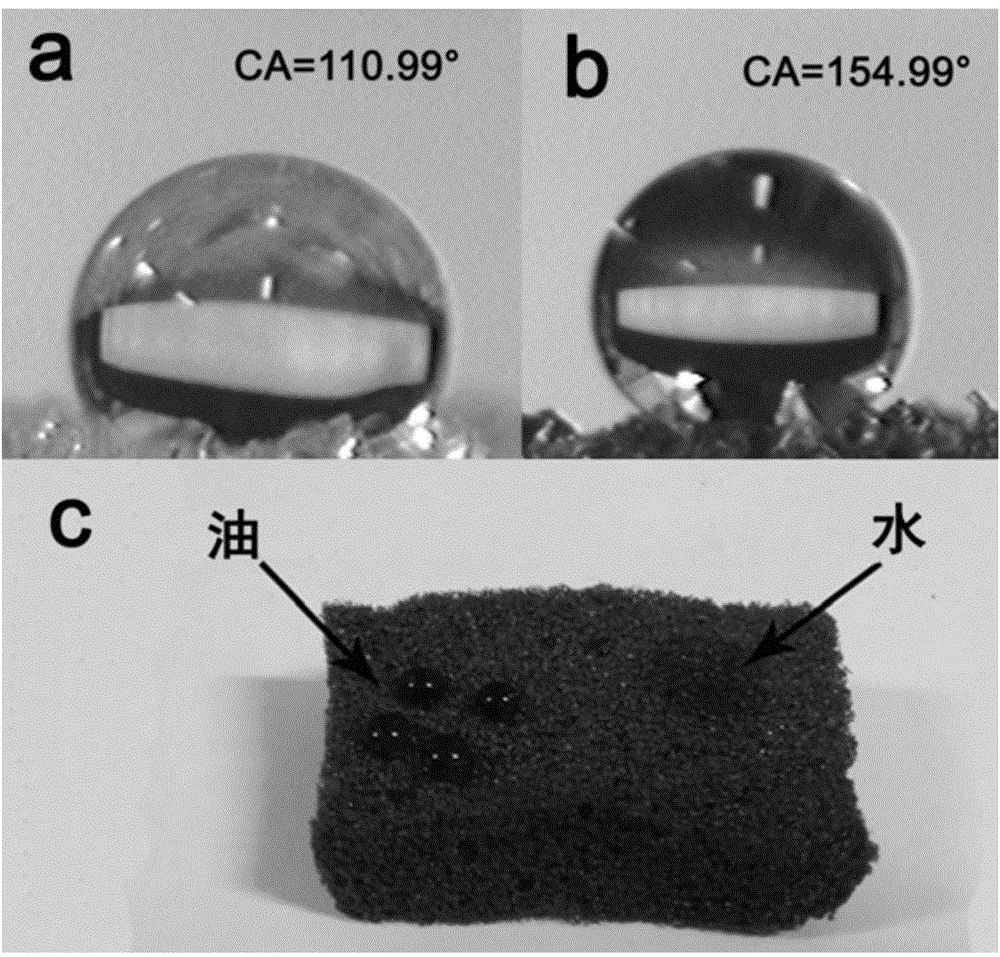

A polyurethane foam and composite foam technology, which is applied in the fields of new graphene oxide-polyurethane composite foam materials, oil-water separation and oil storage and transportation, can solve the problems of high cost and low efficiency of the preparation process, and achieve strong mechanical properties and convenient preparation methods , enhance the effect of adsorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

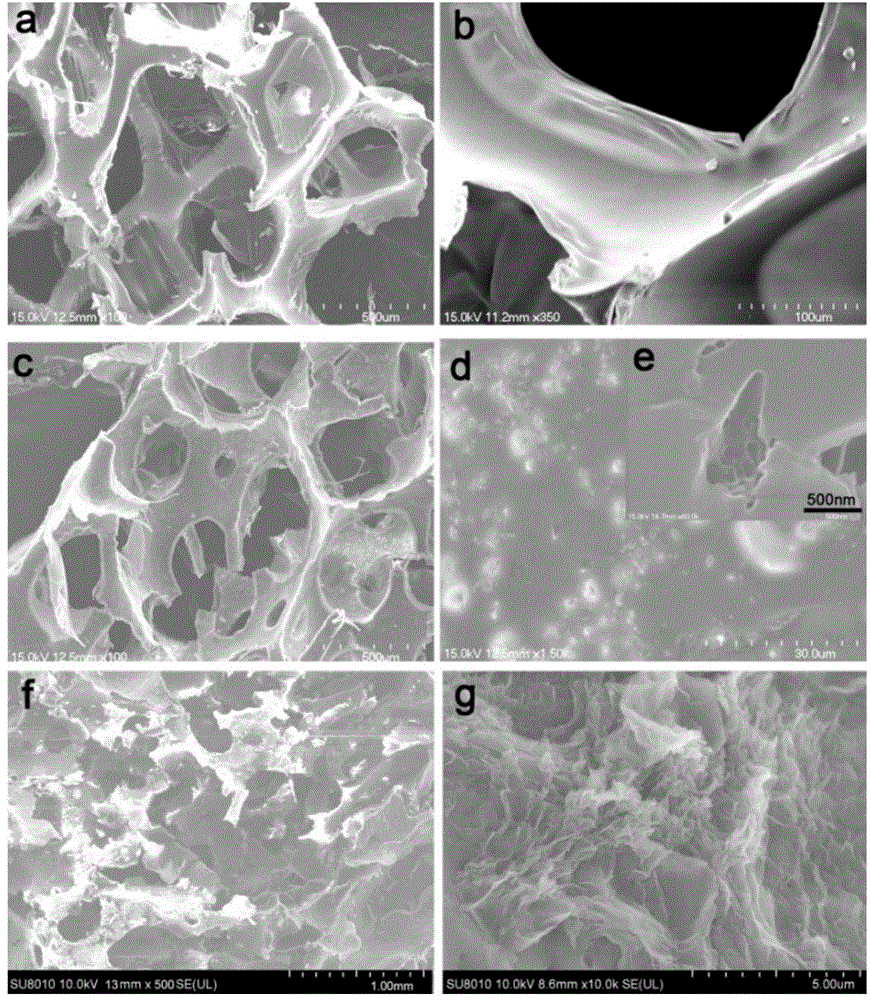

[0040] Example 1: Synthesis of polyurethane foam (porous PU) with a porous skeleton.

[0041] At room temperature, 100g of propylene glycol polyether 3000 (Jurong Ningwu New Material Development Co., Ltd.), 100g of MDI (Huntsman Chemical Trading Co., Ltd.) , 1g methyl silicone oil (Sinopharm Group Chemical Reagent Co., Ltd.), 0.5g triethylenediamine (Sinopharm Group Chemical Reagent Co., Ltd.), 0.2g stannous octoate (Sinopharm Group Chemical Reagent Co., Ltd.), 6g water, 10g nano calcium carbonate (Shanghai Crystal Pure Biochemical Technology Co., Ltd.) and 10g of graphene oxide (Shanghai Crystal Pure Biochemical Technology Co., Ltd.) were mixed and stirred for 2 minutes, and the mixture in the container was left to stand for 10 minutes. After it was foamed and hardened for 2 hours, it was washed with acetone Finally, according to the weight-volume ratio of 1g:5mL, the foam was placed in 1mol / L hydrochloric acid ethanol solution for 2h, and 200g of polyurethane foam (porous PU...

Embodiment 2

[0042] Example 2: Synthesis of polyurethane foam (porous PU) with a porous skeleton.

[0043]At room temperature, 200g of propylene glycol polyether 3000 (Jurong Ningwu New Material Development Co., Ltd.), 200g of MDI (Huntsman Chemical Trading Co., Ltd.) , 10g methyl silicone oil (Sinopharm Chemical Reagent Co., Ltd.), 2g triethylenediamine (Sinopharm Chemical Reagent Co., Ltd.), 2g stannous octoate (Sinopharm Jingchun Biochemical Technology Co., Ltd.) and 100g graphene oxide (Shanghai Jingchun Biochemical Technology Co., Ltd.) were mixed and stirred for 5 minutes, and the mixture in the container was left to stand for 10 minutes. The weight-to-volume ratio of 1g:5mL put the foam in 2mol / L hydrochloric acid ethanol solution for 2h, take it out and dry it to get 400g of polyurethane foam (porous PU) with porous skeleton.

Embodiment 3

[0044] Embodiment three: cross-linking of graphene oxide and polyurethane foam.

[0045] Submerge 100g of the polyurethane foam (porous PU) with a porous skeleton obtained in Example 1 into 200mL of graphene oxide solution with a concentration of 4mg / mL, add 10mL of ethylenediamine, squeeze continuously to remove air bubbles, and react at 80°C After 8 hours, 105 g of graphene oxide-polyurethane composite foam (porous PUrGO) was obtained after washing and drying.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com