Method for preparing few-layer MoS2 nanosheets

A nanosheet, volume ratio technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve problems such as difficulty in nanosheet preparation, and achieve high product purity, simple operation, and good repeatability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

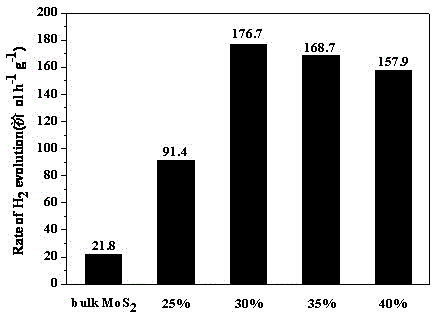

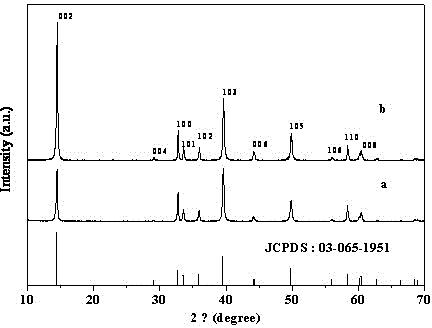

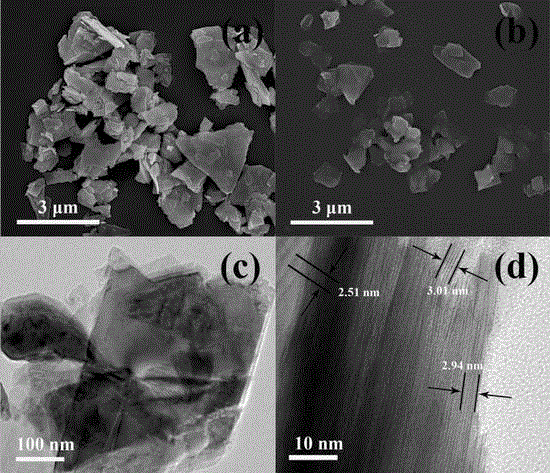

[0014] The preparation method of the present invention is as follows: respectively prepare four parts of 100 milliliters of ethanol solutions with proportions of 25%, 30%, 40% and 45% respectively, place them in a 250ml three-necked flask, and weigh four parts of 0.1 gram of MoS 2 The powders were respectively put into the above mixed solution, and then the three-necked flask was placed in a water bath to raise the temperature and reflux, and when the temperature reached 80°C, it lasted for 3 hours, and then naturally cooled to room temperature. The mixed solution was centrifuged at 2000 rpm (rev / min) for 20 minutes, and the supernatant was taken, filtered through an organic filter with a pore size of 0.22 micron, and dried at 60°C for 12 hours to obtain the target product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com