H-shaped flue gas dust removal desulfurization reactor and flue gas desulfurization method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

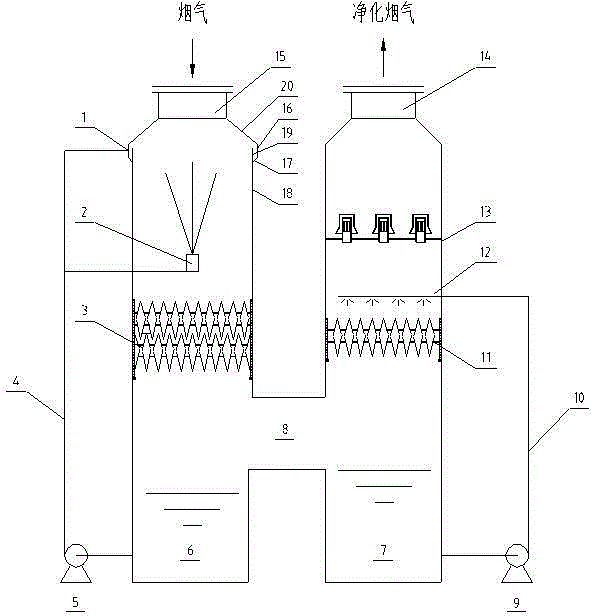

Embodiment 1

[0063] A high-temperature flue gas temperature is 180°C, and the gas volume is 180,000Nm 3 / h,SO 2 The concentration is 800mg / Nm 3 , dust content 500 mg / Nm 3 .

[0064] Reactor operating conditions: operating temperature is 170°C, operating pressure is normal pressure, the pH value of the primary absorption liquid is 6-7, and the pH value of the secondary absorption liquid is 8-9. The turbulent liquid-gas ratio is 6:1, NaOH solution is used as the absorbent, and the gas-liquid is in countercurrent contact; the packing assembly operates with a liquid-gas ratio of 3:1.

[0065] After being treated by the present invention, the flue gas temperature is 60°C, the desulfurization efficiency is 98%, and the dust removal efficiency is 99%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com