Liquid injecting, sealing and forming method of soft packaging lithium-ion battery

A technology of lithium-ion batteries and chemical formation methods, which is applied in the manufacture of battery pack parts, non-aqueous electrolyte batteries, electrolyte batteries, etc., can solve the problems of slow pumping speed, high equipment cost, and high cost of aluminum-plastic film, and achieve economical production cost, improve its own performance, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

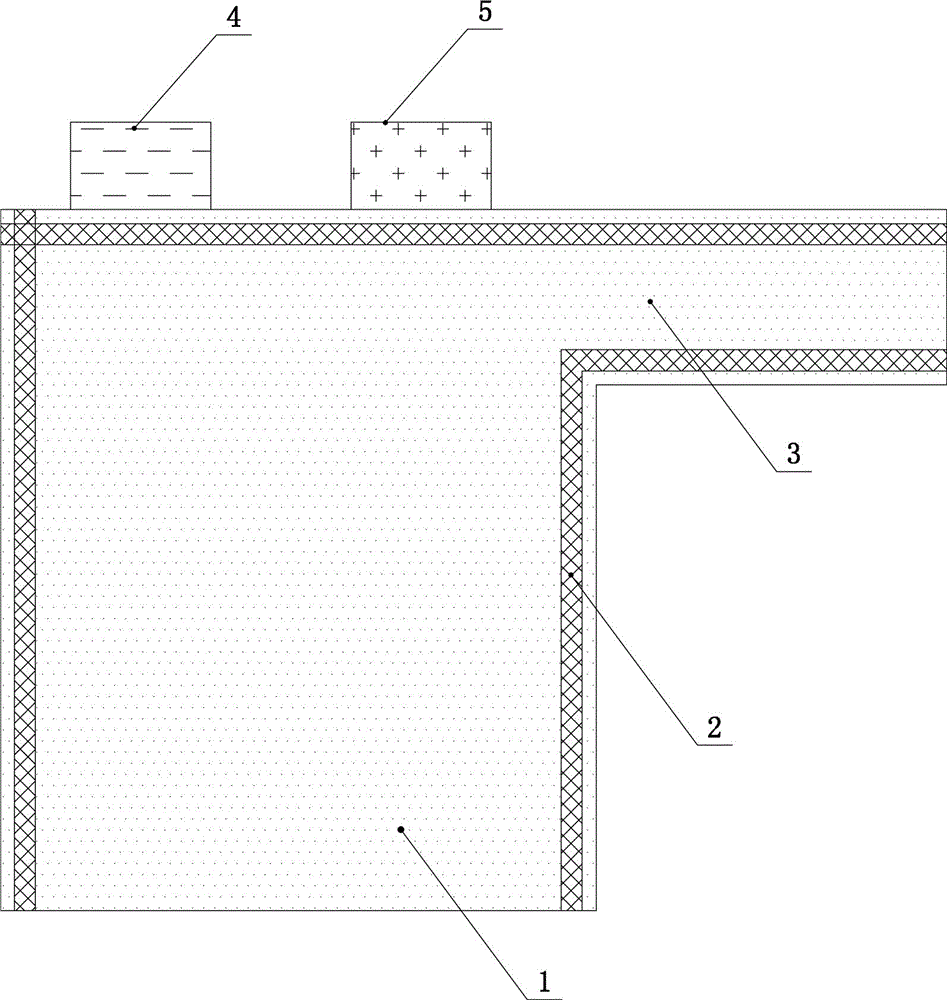

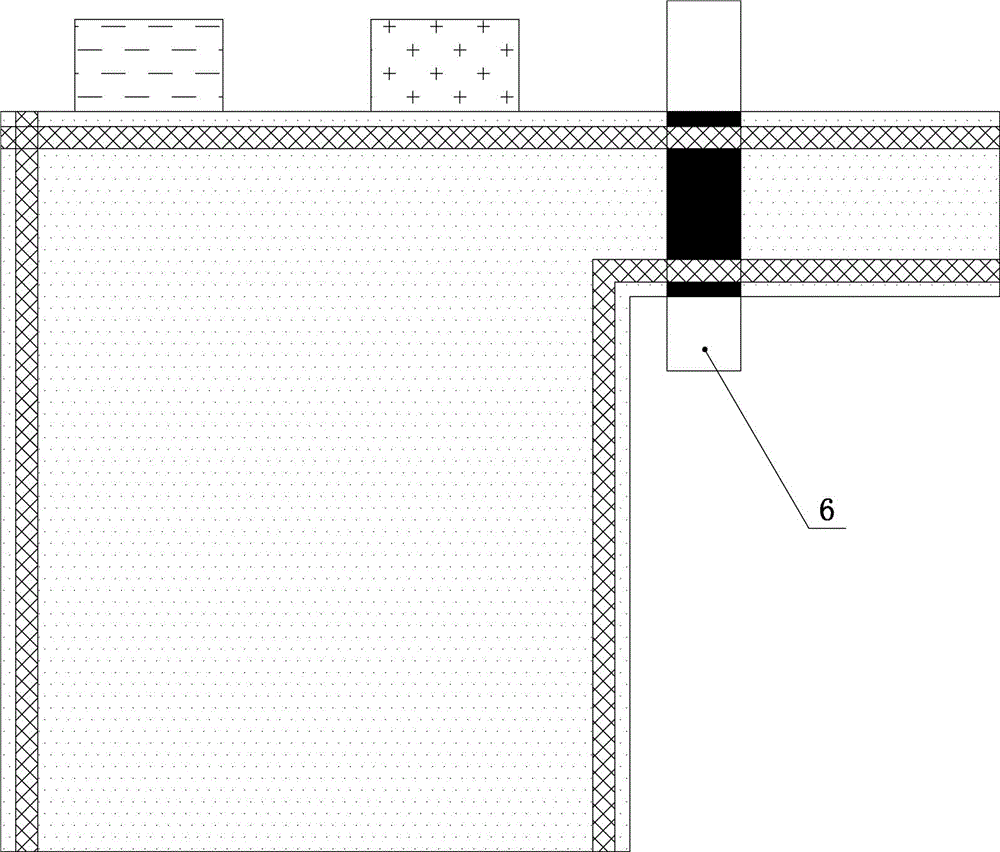

[0017] A method for liquid injection, sealing and formation of a soft-packed lithium-ion battery, taking the production of a soft-packed lithium-ion battery with a model number of HTPF08140200-20Ah-3.3V as an example, including the following steps: packaging one side of the soft-packed lithium-ion battery with an aluminum-plastic film into a The shape of the tubular channel, such as figure 1 As shown in Fig. 1, the flexible packaging cell is vacuum-filled by using the aluminum-plastic film tubular channel, and a spare sealing clip is prepared for each cell. After the liquid injection is completed, the aluminum-plastic film tubular channel is clamped with the sealing clip, as shown in figure 2 As shown, the interior of the soft-packaged lithium-ion battery is isolated from the outside world, and the soft-packaged lithium-ion battery with a sealing cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com