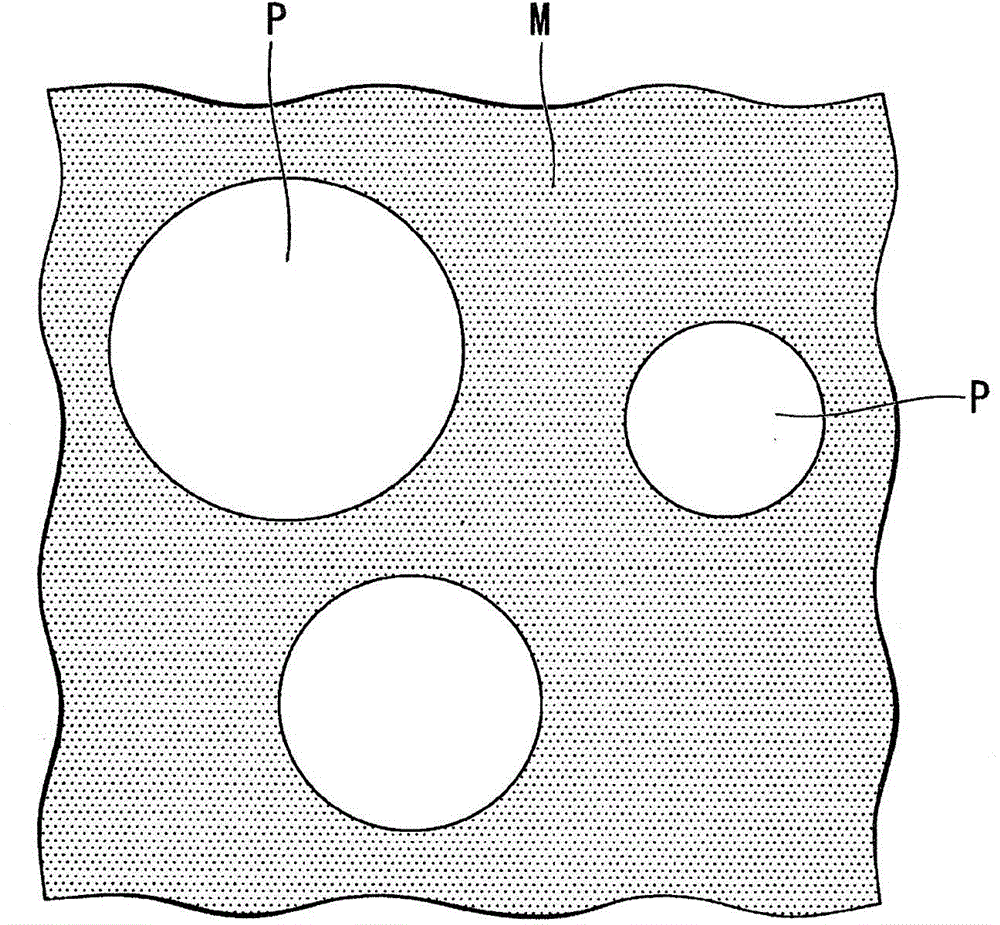

SOLID ELECTROLYTE, METHOD FOR PRODUCING SOLID ELECTROLYTE, AND LITHIUM-ION BATTEry

A technology of a solid electrolyte and a manufacturing method, which is applied to non-aqueous electrolyte storage batteries, electrolytes, lithium storage batteries, etc., can solve the problems of composition change and difficulty in manufacturing formed bodies.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

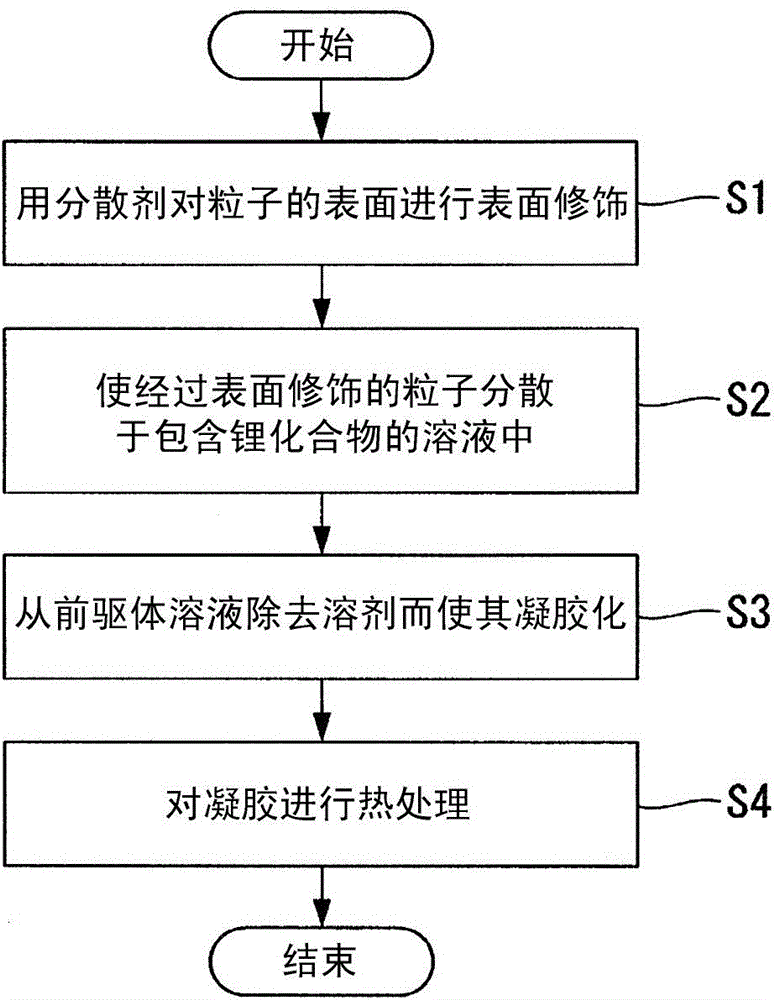

Method used

Image

Examples

Embodiment 1

[0128] Using a planetary ball mill for Li 0.35 La 0.55 TiO 3 (High Purity Chemicals) pulverized to prepare particles with a volume fraction median diameter of 200 nm.

[0129] Next, add Li to 10ml of n-hexadecane 0.35 La 0.55 TiO 3 1 g of particles and 0.05 g of octadecyl monoethoxysilane (Azmax Co., Ltd.) were heated at 180° C. for 2 hours on a hot plate while stirring at 300 rpm using a magnetic stirrer.

[0130] Next, using a centrifuge cooled to 10° C., centrifugation was performed at 15,000 rpm for 10 minutes to settle the particles. After removing the supernatant, the particles were again dispersed in 10 ml of n-hexadecane, and centrifuged again under the same conditions. The supernatant was removed, and the obtained precipitate was dispersed in 10 ml of n-hexadecane to obtain a dispersion of surface-treated particles.

[0131] Next, 0.28 g of tetraethoxysilane (High Purity Chemical) was mixed with 10 ml of the obtained dispersion liquid. In addition, the LiNO 3...

Embodiment 2

[0135] As the particles, Li was synthesized with reference to the non-patent literature (Electrochemical and Solid-State Letters, 15(3)A37-A39(2012)).7 La 3 Zr 2 o 12 Except for the fine particles, a molded body of a solid electrolyte was obtained in the same manner as in Example 1.

Embodiment 3

[0147] Use 0.28g of octadecyltriethoxysilane, and add 4ml of silicone (KF-96-10cs, Shin-Etsu Silicone) and 3ml of indane instead of 0.28g of tetraethoxysilane (High Purity Chemical), and Except for this, a molded body of a solid electrolyte was obtained in the same manner as in Example 1.

[0148] The ionic conductivity of the obtained molded body of the solid electrolyte was measured in the same manner as in Example 1. As a result, the total ionic conductivity was 2.1×10 -4 S / cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| ionic conductivity | aaaaa | aaaaa |

| ionic conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com