Amorphous alloy oil-immersed transformer oil tank with noise reduction function

An oil-immersed transformer and a transformer oil tank technology, applied in the field of transformers, can solve the problems of increasing the cost of the transformer, being expensive, polluting the environment, etc., and achieving the effects of long-lasting noise reduction and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

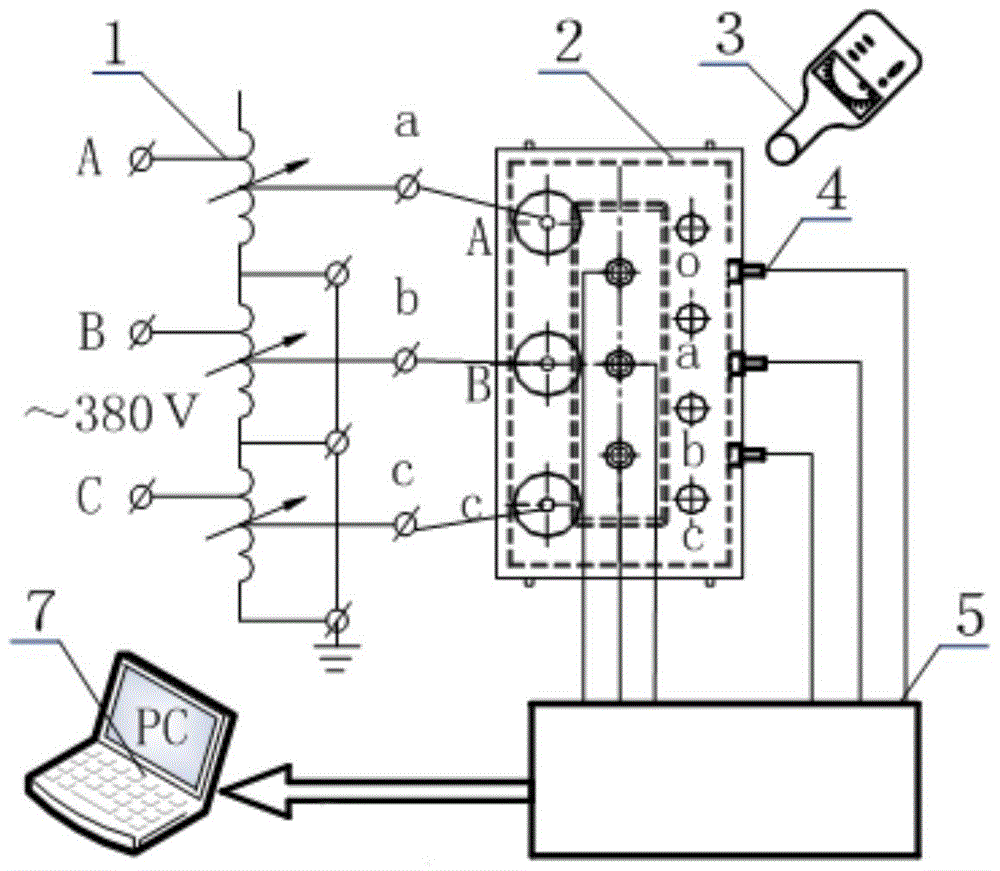

[0024] Such as Figure 1-7 As shown, the amorphous alloy transformer vibration testing device used in the present invention includes a voltage regulator 1 for adjusting voltage and an ICP sensor 4 for vibration testing. The ICP sensor 4 used for vibration testing is sequentially connected to the acquisition card 5 used for data collection and the computer 7 used for data analysis. The data acquisition card 5 is connected with the computer 7 with a data cable with a USB interface. A noise meter 3 is also included, and the noise meter 3 is arranged near the ICP sensor 4 . The test object is SBH15-10 / 0.4 amorphous alloy transformer 2.

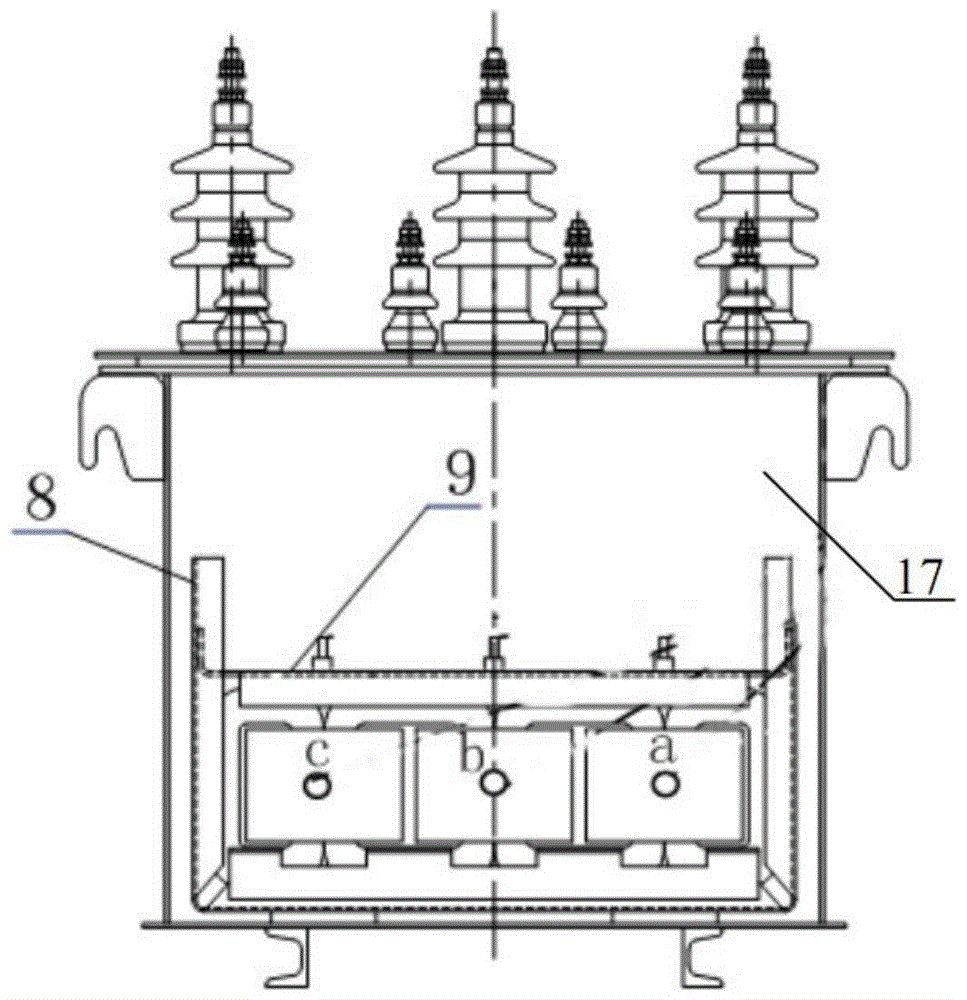

[0025] The amorphous alloy transformer 2 was tested with the rated voltage and in the open circuit state, and the vibration signals of each point were recorded and analyzed. The results of the data analysis are shown in Image 6 , Figure 7 . After comparison, the amplitudes of phase point a and phase point c on the first clip 9 are larger th...

Embodiment 2

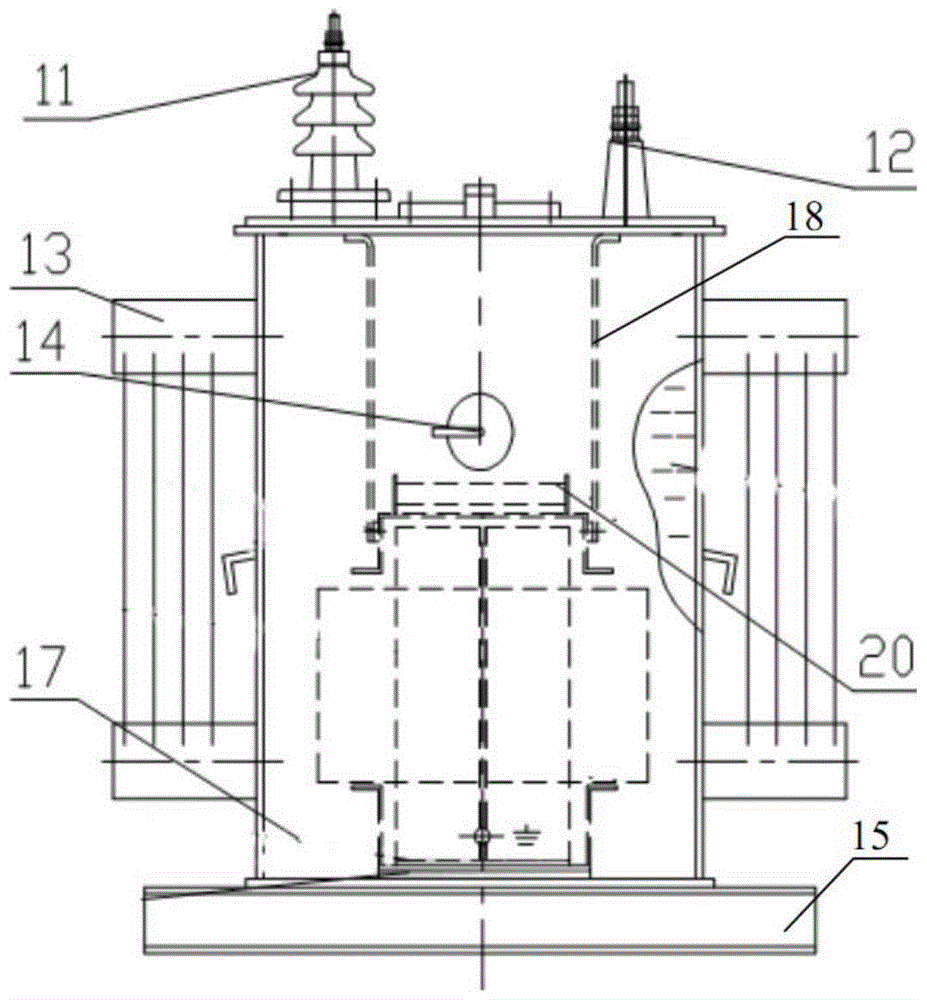

[0029] Amorphous alloy oil-immersed transformer oil tank with noise reduction function, such as Figure 1-7 As shown, the transformer oil tank 17 is included, the cover of the transformer oil tank 17 is provided with a high-voltage bushing 11 and a low-voltage bushing 12, the lower side of the transformer oil tank 17 is provided with a base 15, and a shock absorber is provided between the transformer oil tank 17 and the base 15, The transformer oil tank 17 is provided with a first clip 9, and the first clip 9 is horizontally distributed. The first clip 9 is provided with two first reinforcing ribs 22, and a second reinforcing rib 22 is arranged between the two first reinforcing ribs 22. Ribs 21, two first ribs 22 and second ribs 21 form an H-shaped structure; the side wall of the transformer oil tank 17 is vertically provided with two third ribs 23, and two third ribs 23 are arranged between There is a fourth rib 24, and the third rib 23 and the fourth rib 24 form an H-shaped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com