Vibrating reed, angular velocity sensor, electronic device, moving object, and method for manufacturing vibrating reed

一种角速度传感器、振动片的技术,应用在陀螺仪/转向感应设备、陀螺效应进行速度测量、速度/加速度/冲击测量等方向,能够解决电荷损失等问题,达到电荷损失抑制、提高电场效率、缩窄电极间距离的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] Hereinafter, one embodiment of the present invention will be described with reference to the drawings. In addition, the present embodiment described below does not unduly limit the content of the present invention described in the claims, and not all the configurations described in the present embodiment are necessarily essential to the solutions of the present invention.

[0064] 1. Overview of vibrator

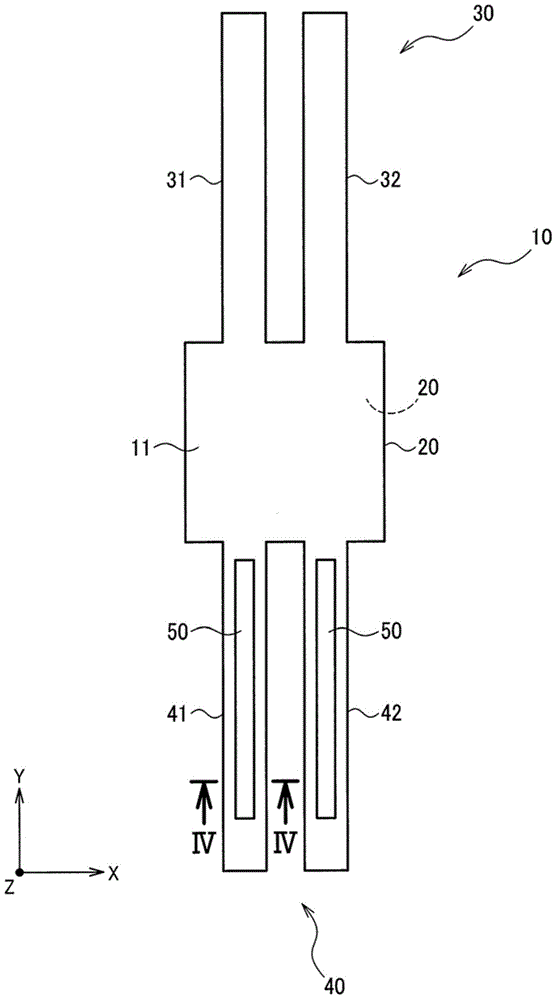

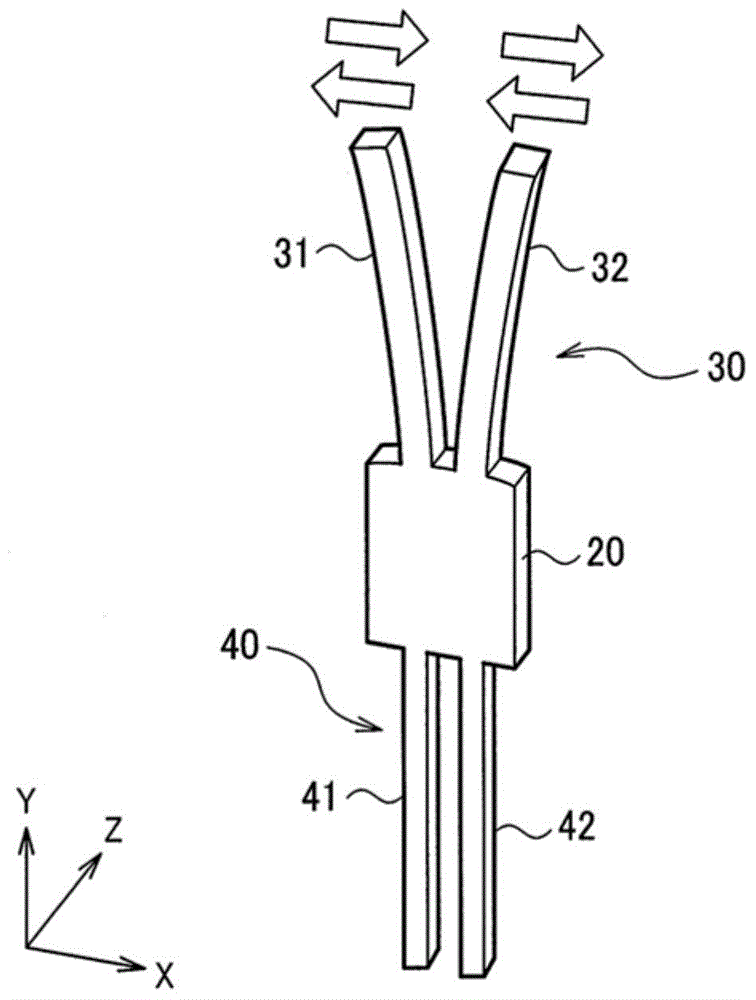

[0065] figure 1 The vibrating piece main body of the vibrating piece 10 is schematically shown in a state before electrodes are formed. Here, the vibrating piece 10 of the present embodiment has a first main surface 11 and a second main surface 12, which are aligned with each other on the X-axis (second axis) and on the plane. The X-axis and the Y-axis perpendicular to each other extend on an X-Y plane and face each other. In addition, let the axis perpendicular to the first main surface 11 and the second main surface 12 be a Z-axis. When the piezoelectric body fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com