External threaded fastener with pre-formed slot at tail end and capability of realizing riveting assembly and use method thereof

An external thread and fastener technology, applied in the direction of threaded fasteners, locking fasteners, connecting components, etc., can solve the problems of poor anti-loosening performance, non-removable and reusable riveted connections, and non-re-twisting. , to achieve the effect of good anti-loosening performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

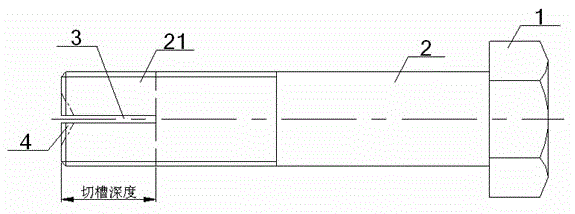

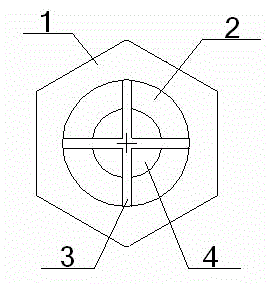

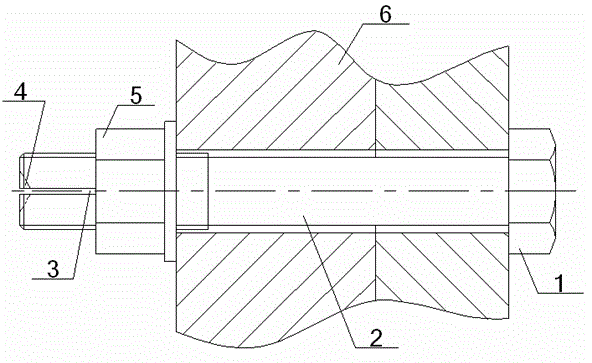

[0053] see Figure 1 to Figure 3 , an externally threaded fastener whose tail end is pre-grooved to achieve riveted assembly, including a screw head 1 and a screw rod 2, the externally threaded fastener refers to a bolt, a screw or a stud, and the cross section of the screw head 1 The diameter is greater than the diameter of the cross section of the screw 2, the bottom of the screw head 1 is vertically connected to the top of the screw 2, and the bottom of the tail end of the screw 2 is provided with a through-type slot 3 along its radial direction, the slot 3 The cutting direction extends from the bottom of the tail end of the screw rod 2 to its top, and the number of slots 3 is at least one. If the number of slots 3 is at least two, the arrangement of all slots 3 is evenly distributed on the same circumference; The slot 3 is located on the screw tail end 21. The screw tail end 21 refers to the exposed part of the screw 2 after the nut 5 is assembled. Preferably, the depth of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com