Digging mechanism of potato harvester

A harvester and potato technology, which is applied to digging harvesters, harvesters, agricultural machinery and implements, and can solve problems such as complex structures, large scattered areas of potatoes, and falling off of transmission arms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below by means of specific embodiments:

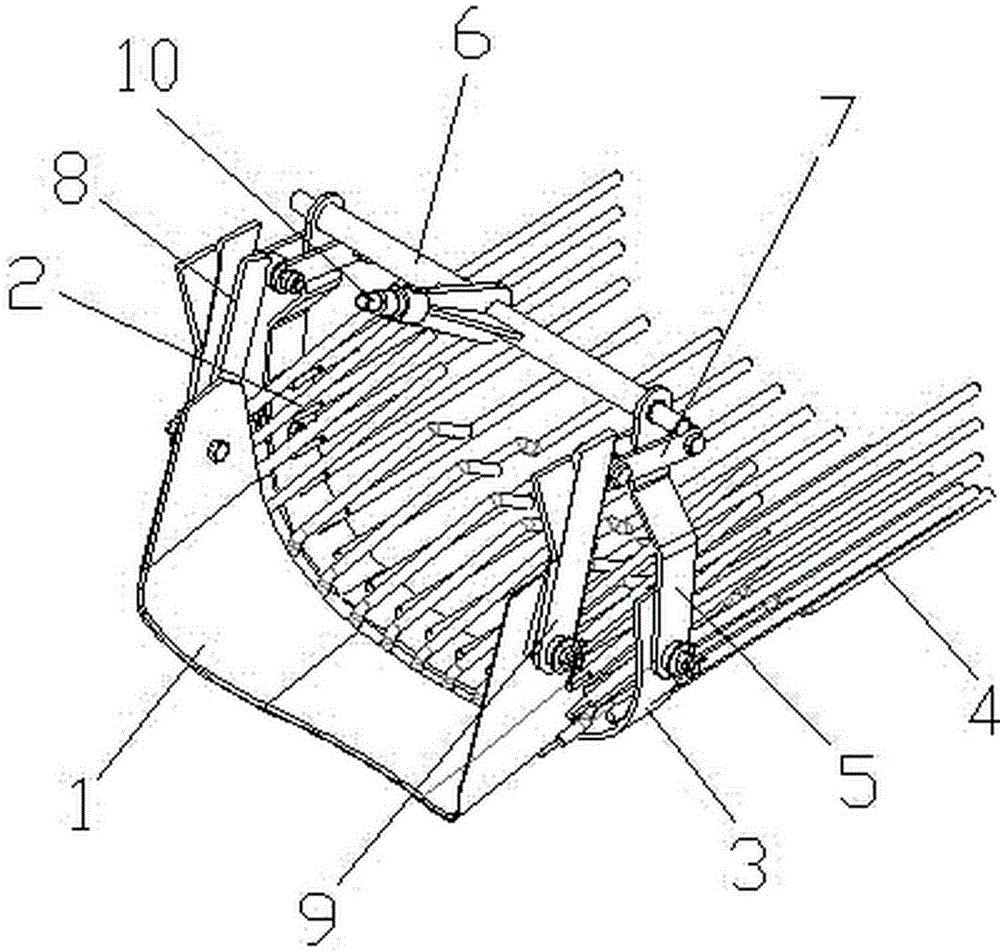

[0024] as attached figure 2 Shown: the digging mechanism of the potato harvester in this embodiment includes a digging shovel and a sieve bucket. The excavating shovel includes a shovel head 1 and several first support rods 2 connected with the shovel head 1, and the longitudinal section of the shovel head 1 is U-shaped. The first support rod 2 is located behind the shovel head 1 and is fixedly connected with the shovel head 1. A support bar 2 is distributed corresponding to the two side walls and the bottom of the shovel head 1, so that the first support bar 2 forms a U-shape corresponding to the shovel head 1 .

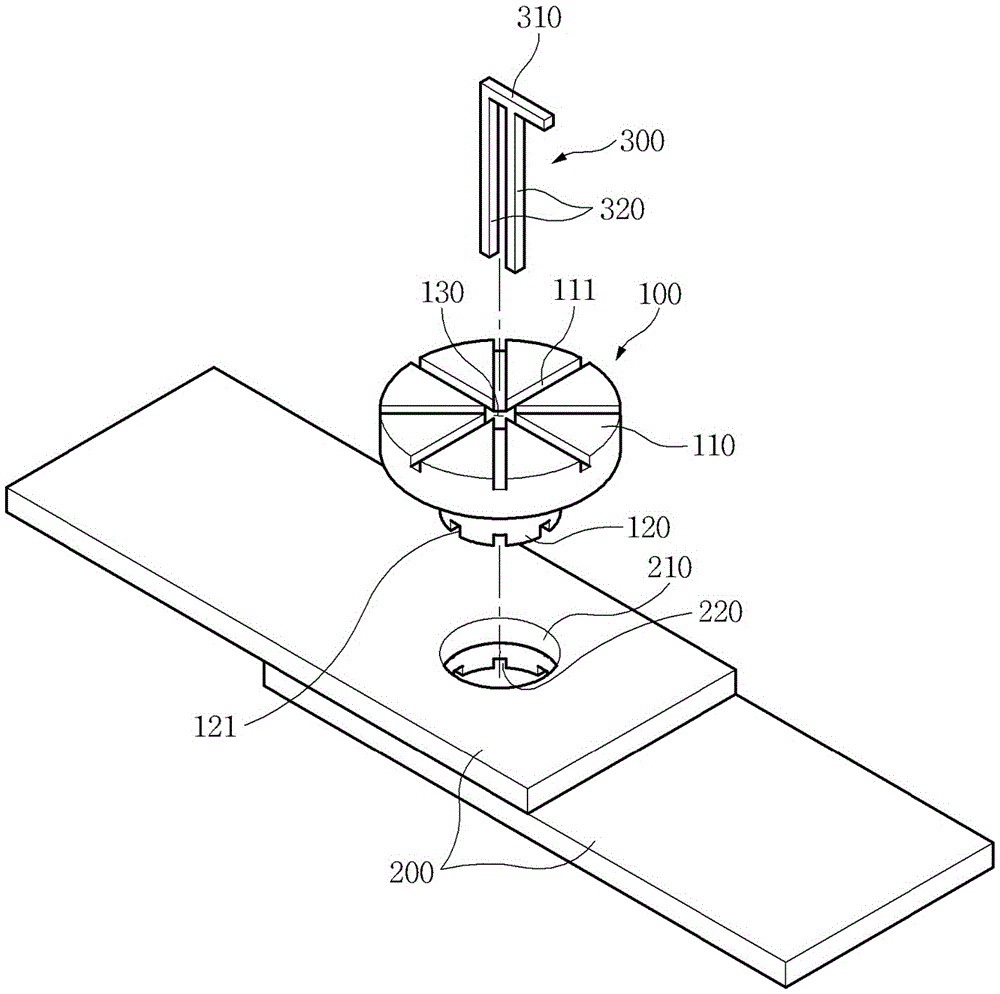

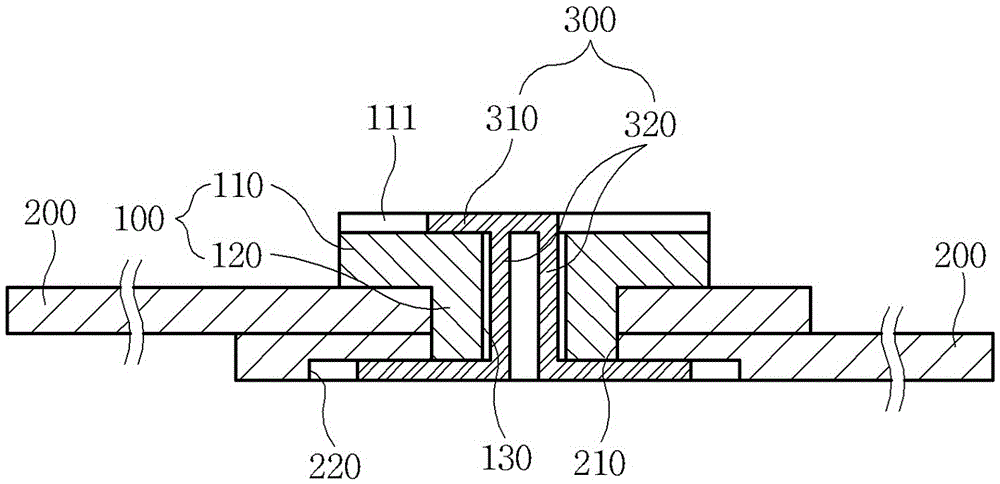

[0025] Such as figure 1 , 3 As shown, the digging mechanism of the potato harvester of the present invention includes a positioning connector. The positioning connector includes a positioning sleeve 100 and a positioning lock 300. The positioning sleeve in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com