Automatic pressing device with spring for mesh belt transmission chain

A compression device and transmission chain technology, applied in the direction of transportation, packaging, conveyors, etc., can solve the problems that affect the production efficiency of food production lines, the discount of food transportation efficiency, and the production line cannot be separated from people, so as to save labor costs and have a simple structure , the effect of saving power source

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and embodiments, which are only used to explain the present invention and do not limit the protection scope of the present invention.

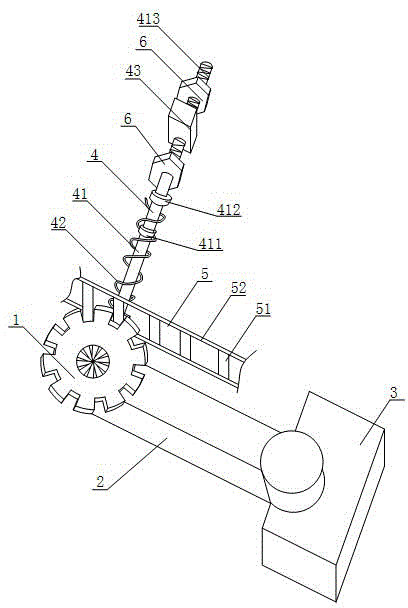

[0014] Such as figure 1 As shown, the spring automatic compression device for the mesh belt transmission chain is connected to one side of the transmission chain 5. The transmission chain 5 includes several pin shafts 51 and connecting parts 52 for connecting every two pin shafts; , the swing arm 2, the fixed support 3, the spring adjustment device 4, the gear of the pressing wheel 1 is meshed with the pin shaft 51 of the drive chain 5, the pressing wheel 4 is fixedly connected to the fixed support 3 through the swing arm 2, And the swing arm 2 rotates with the fixed support 3 as the center of rotation; the spring adjustment device 4 is vertically connected to one side of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com