Split integrated underground passage steel mold plate trolley and construction method thereof

A technology of underground passages and steel formwork, which is applied in the direction of underground chambers, tunnels, tunnel linings, etc., can solve the problems of inability to realize continuous concrete pouring construction, long construction time, and difficult cleaning of side formwork, so as to achieve easy cleaning and Apply release agent, save manpower and material resources, and occupy a small area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

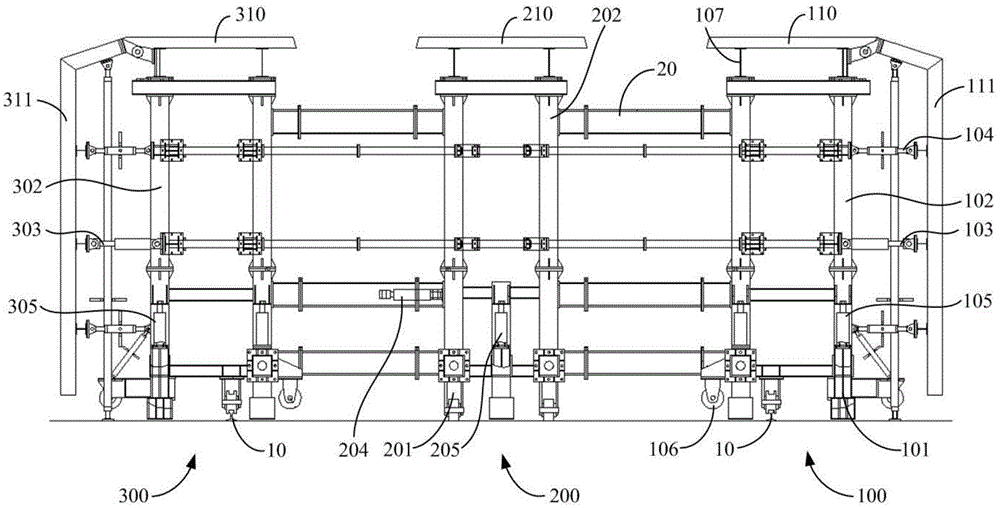

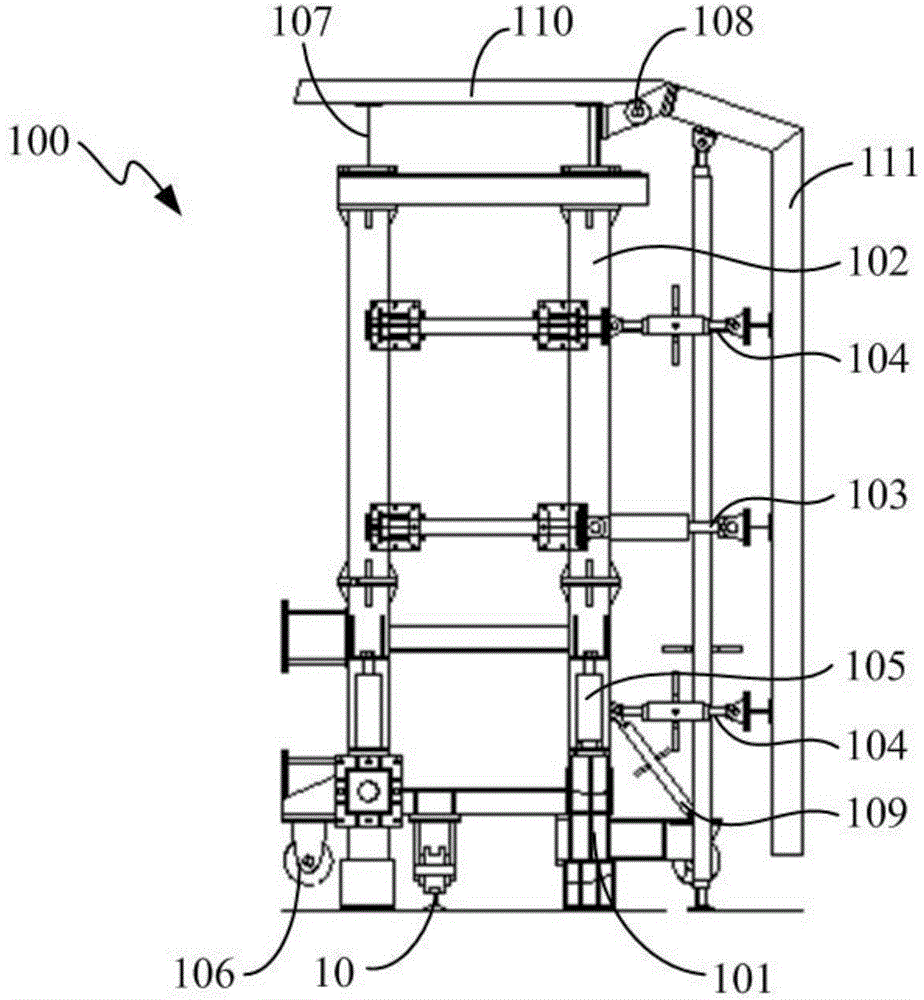

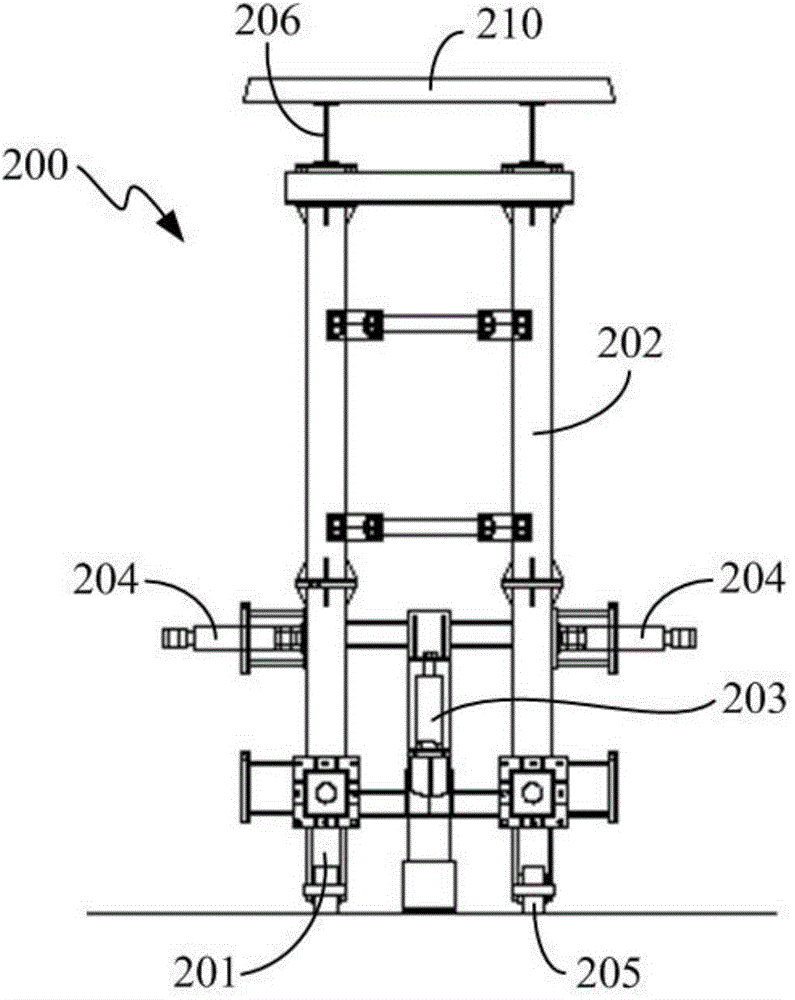

[0035] Example 1: Combining Figure 1 to Figure 8 Illustrate that the split integrated underground passage steel formwork trolley of the present invention is used to install the formwork group for pouring underground passage concrete, such as figure 1 As shown, the steel formwork trolley of this embodiment includes three frame-type formwork support devices arranged in sequence along the cross-section of the underground passage, from right to left are frame-type formwork support device one 100, frame-type formwork support device two 200 and Frame formwork support device three 300, the three frame formwork support devices (100, 200, 300) are connected as a whole through several detachable box-shaped beams 20 arranged horizontally, and frame formwork support device one 100 and frame formwork support device The bottom of formwork support device 3 300 is equipped with a running mechanism, which can drive the frame type formwork support device (100, 200, 300) to move along a pair of...

Embodiment 2

[0045] Embodiment 2: Combination Figure 8 to Figure 10 , and refer to Figure 1 to Figure 7 Illustrate the construction method of the split-integrated underpass steel formwork trolley of the present invention, and the specific steps are as follows:

[0046] Step 1: Install the formwork group on the steel formwork trolley, and arrange three frame-type formwork support devices (100, 200, 300) in sequence along the cross-section of the underground passage 50, and three frame-type formwork support devices (100, 200, 300) After arriving at the designated work position, its vertical position is connected up and down by detachable box-shaped beams 20, and it is stably and firmly located in the underground passage 50. The frame formwork support device (100, 200, 300) passes through the vertical hydraulic cylinder (105, 205, 305) are adjusted to the standard height, after the bolts are connected between two adjacent frame formwork support devices (100, 200, 300), the roof formwork su...

Embodiment 3

[0051] Example Three: Combining Figure 11 , and see Figure 1 to Figure 10 Illustrate the construction method of the split-integrated underground passage steel formwork trolley of the present invention. The difference from Embodiment 2 is that this embodiment is a pouring construction operation under the condition that the underground passage 50 has several curved arc sections, such as Figure 11 As shown, when there is a curved arc section with a radius R of 400m in the underground passage, the steel formwork trolley is decomposed into a steel formwork trolley unit 1 with a length L of 12.5m, and the box-shaped beam on the steel formwork trolley 20 is dismantled, and the three frame formwork support devices (100, 200, 300) are bolted directly into a whole, so that the width of the steel formwork trolley is narrowed, and it is convenient to move forward along the arc section of the curve in the underground passage 50. The steel formwork trolley is shortened, so that the prof...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com