Urban rail transit shock absorption type floating slab rail system

A technology of urban rail transit and floating slabs, applied in the field of rail transit, can solve the problems of physical and mental health of residents and structural building safety hazards, unsatisfactory vibration isolation performance of floating slabs, vibration amplification, etc., to achieve improved vibration isolation effect, installation Easy and flexible to disassemble or maintain, reduce vibration and secondary noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

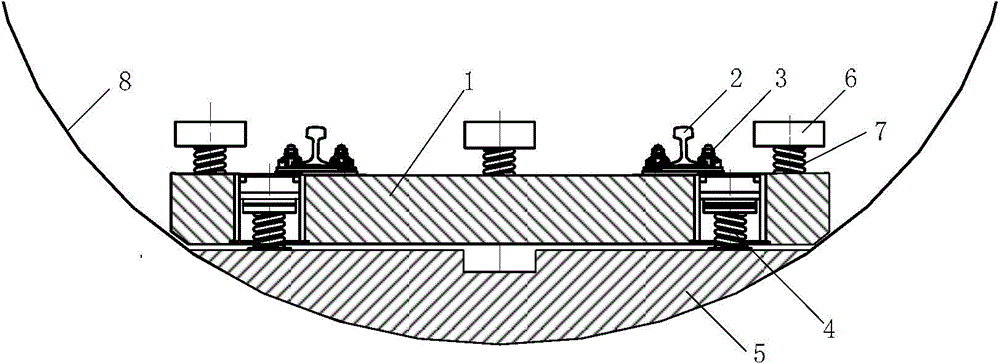

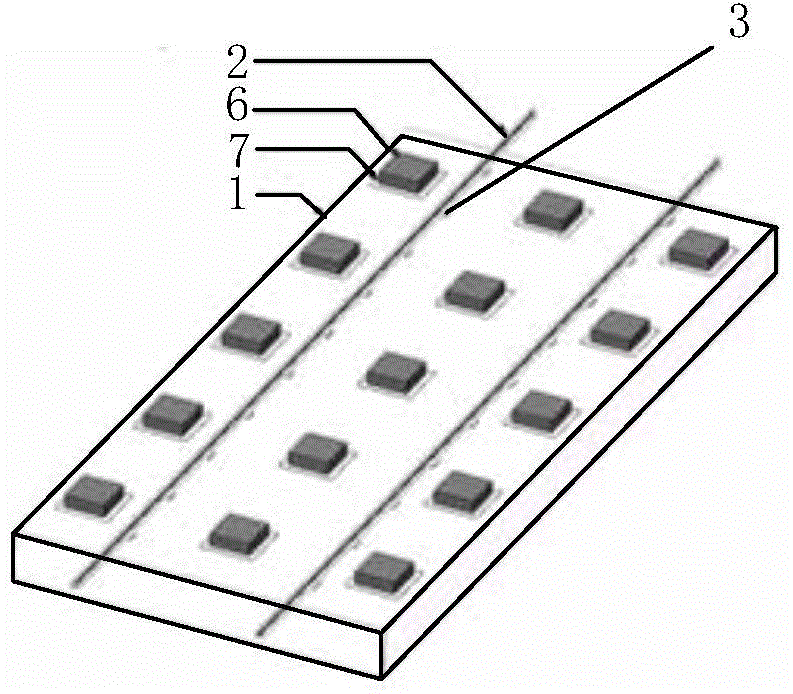

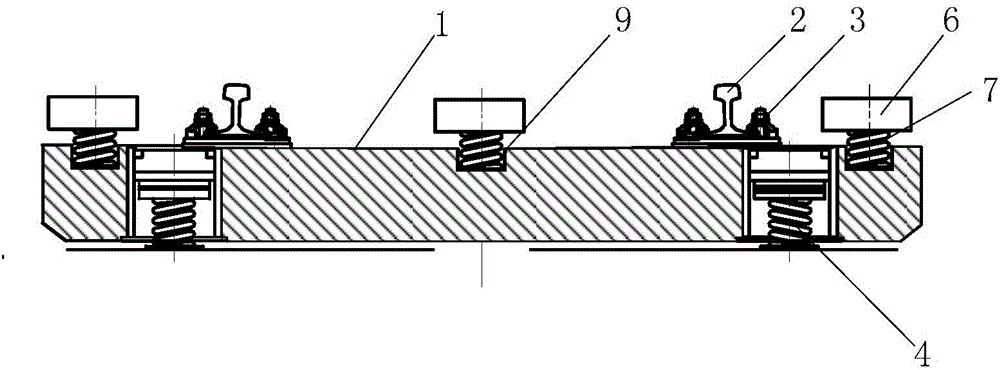

[0027] see Figure 1-5 , the present invention is an urban rail transit vibration-absorbing floating slab track system, which includes a floating slab 1, a tunnel base 5, a rail 2 and a vibration-absorbing block 6; the rail 2 is fixed on the floating slab 1 by a fastener 3; The floating plate 1 is placed on the tunnel base 5 through the vibration isolator spring 4, and is laid continuously along the line extension direction; the tunnel base is poured in the tunnel 8; the floating plates 1 are set within the width range There are several rows of vibration-absorbing blocks 6 , and several vibration-absorbing blocks 6 are arranged within the length range; the vibration-absorbing blocks 6 are discretely arranged on the upper surface of the floating plate through elastic members 7 .

[0028] On the other hand, the vibration-absorbing blocks 6 can a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com