Double-layer vibration isolation chair

A seat and vibration isolation technology, which is applied to vehicle seats, seat suspension devices, special positions of vehicles, etc., can solve the problems of restricting popularity, poor low-frequency vibration isolation effect, and large space occupation, and achieve reliability and High comfort, improved vibration isolation performance, simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific embodiments of the present invention will be described in further detail below through the description of the embodiments with reference to the accompanying drawings.

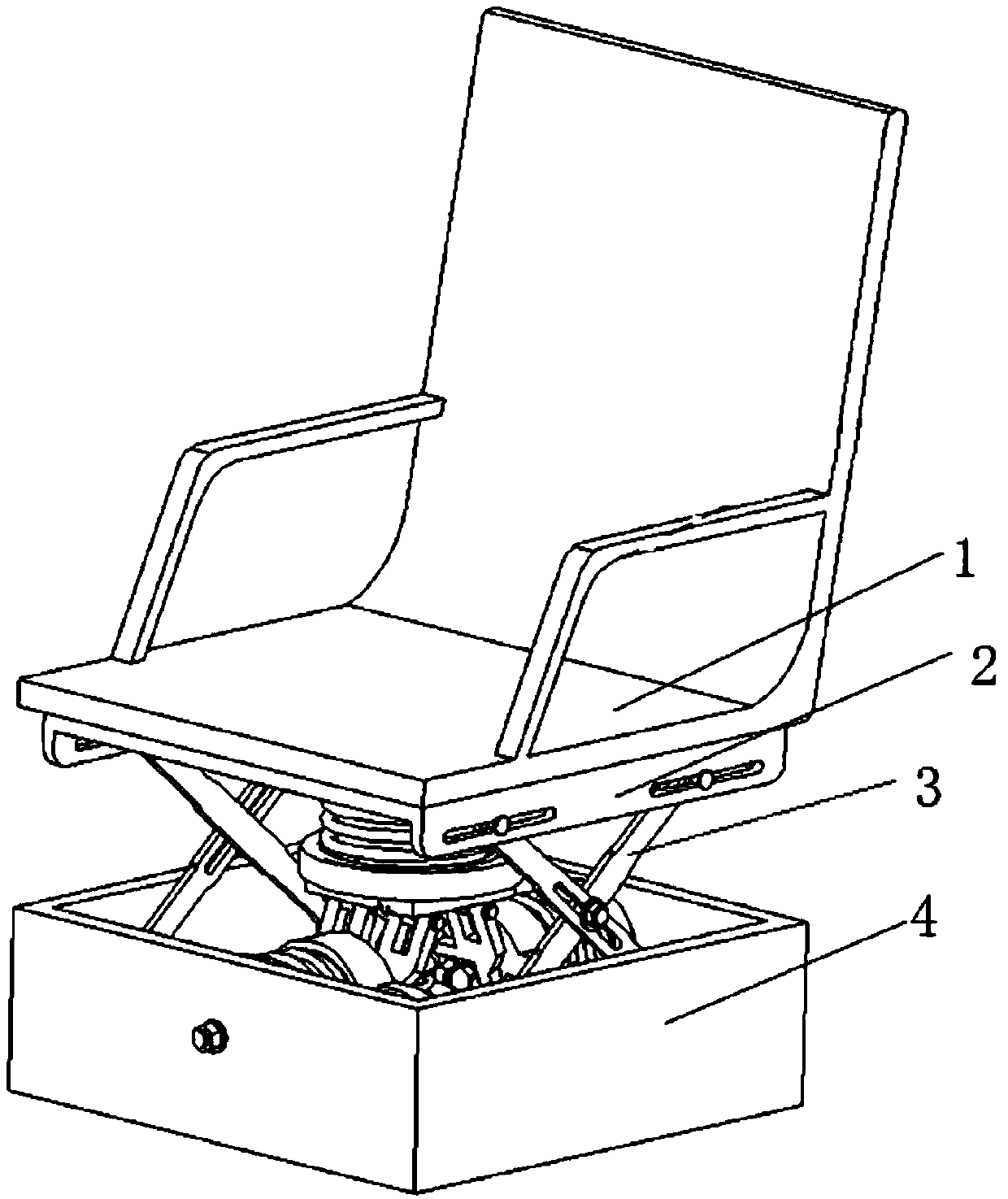

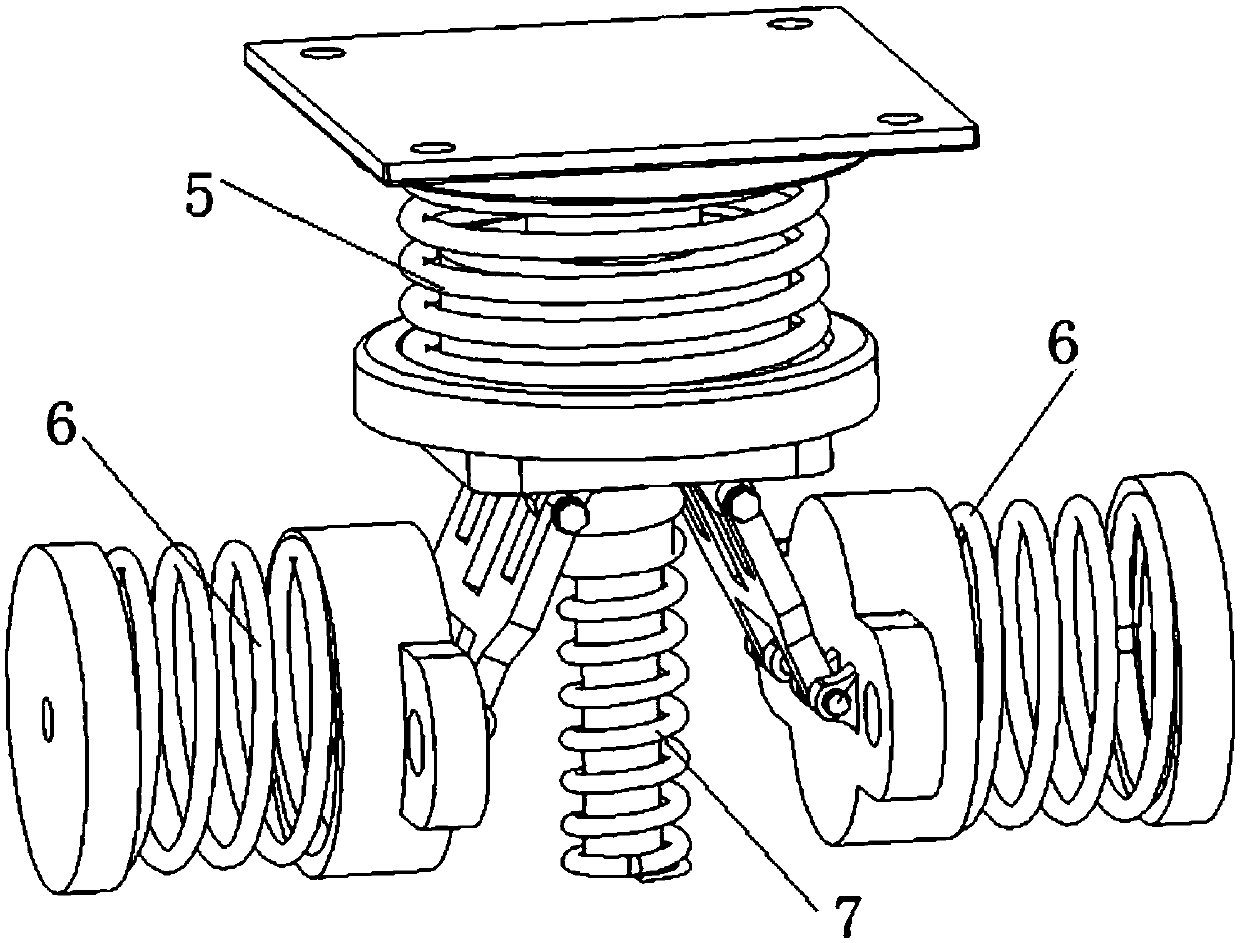

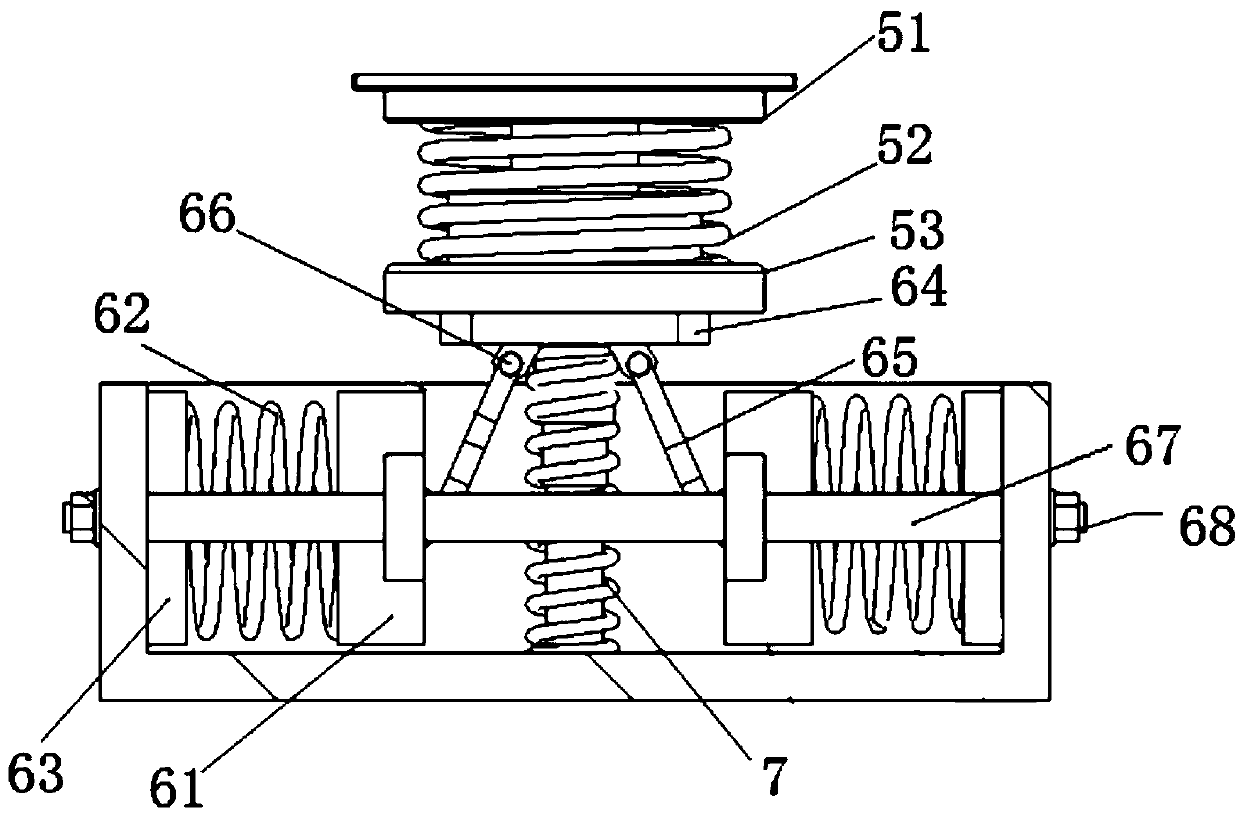

[0029] The double-layer vibration isolation seat of the present invention, such as figure 1 , 2 , 3 and 4, it includes a seat surface 1 and a vibration isolation platform 2 arranged under the seat surface 1, and a seat base 4 is arranged under the vibration isolation platform 2. Between the seat base 4 and the vibration isolation platform 2, a first layer of vibration isolation structure located on the lower layer and a second layer of vibration isolation structure 5 located on the upper layer are provided. The first-layer vibration isolation structure includes vertically arranged vertical damping springs 7 and negative-stiffness vibration isolation structures 6 arranged on the front and rear sides of the vertical damping spring 7 , and the second-layer vibration isolation structure 5 is ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com