Preparation method of aluminized paper for beer labels and aluminized paper obtained by preparation method

A technology of aluminized paper and labels, applied in chemical instruments and methods, paper, papermaking, etc., can solve the problems of non-off-label, unsatisfactory alkali penetration of aluminized paper, and no strict limit on thickness, etc., and achieves appropriate alkali penetration time. The effect of stable and controllable moisture and improved curl resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

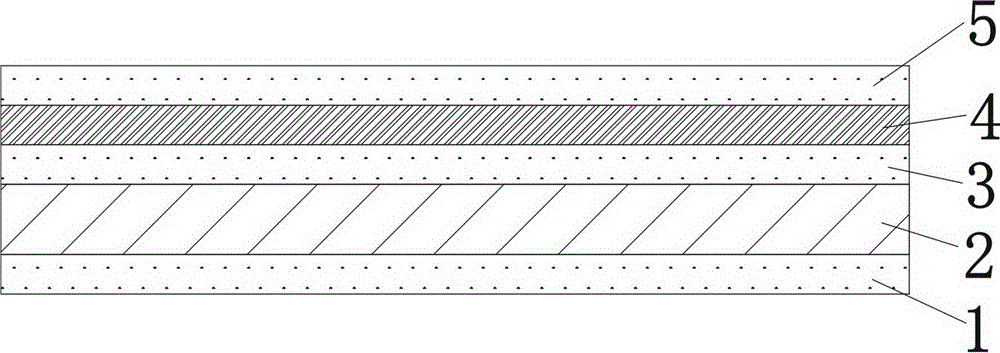

[0020] Such as figure 1 Shown is the aluminized paper used for the beer label of the present invention, the aluminized paper is back coating 1, wet strength paper layer 2, glue layer 3 with special edition laser pattern, aluminized layer 4 and surface from bottom to top Coating 5.

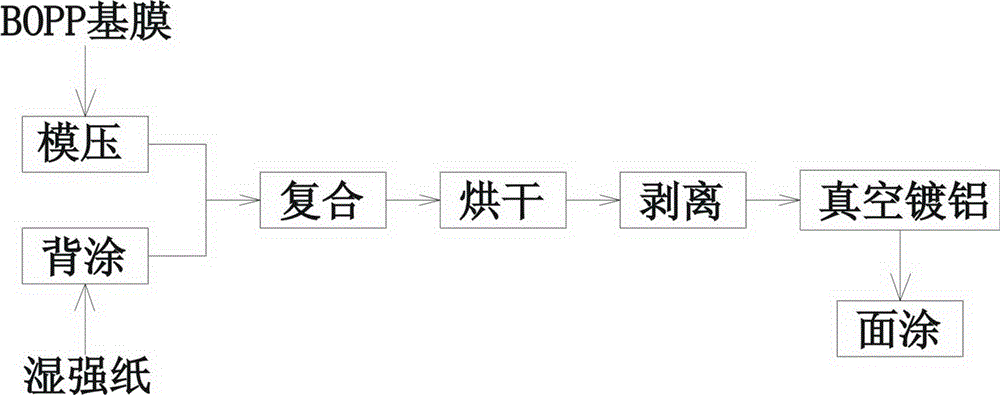

[0021] The preparation method of aluminized paper of the present invention is as figure 2 As shown, it includes in turn: (1) making laser film, using the production method of UV copy seamless laser effect plate roller to mold the BOPP transfer base film to obtain a laser film with a beer trademark special edition laser pattern; (2) paper For back coating, the wet strength paper (68g / m 2 , Moisture 4-6%) back coating, use 300 mesh steel roller as the coating roller, wet coating amount is 4.5g / m 2 , The drying temperature is 65-70°C and the machine speed is 90m / min to form a back coating; (3) Gluing, compounding, drying, and peeling, first use the transfer glue to coat the side of the laser film ...

Embodiment 2

[0023] (1) To make the laser film, the BOPP transfer base film is molded by using the production method of UV copying the seamless laser effect plate roller to obtain the laser film with the special edition laser pattern of the beer trademark; The acrylic emulsion with a viscosity of 13% and a viscosity of 18-20s on the wet strength paper (68g / m 2 , water content 4-6%) for back coating, use 300 mesh steel roller as the coating roller during back coating, wet coating amount is 4.8g / m 2 , The drying temperature is 70-75°C and the machine speed is 90m / min to form a back coating; (3) Gluing, compounding, drying, and peeling, first use transfer glue to coat the side of the laser film with the laser pattern, When coating, choose a glue roller with a hardness of 60 degrees, and adjust the pressure of the glue roller to about 3.2kg to keep the glue amount at 5.5g / m 2 , and then compound the laser film coated with glue with the front of the paper, the pressure of the composite pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com