Preparation method of carboxylic butadiene-styrene latex

A carboxylated styrene-butadiene latex and emulsifier technology, which is applied in the field of chemical manufacturing, can solve problems such as uneven molecular weight and large particle size distribution range, and achieve the effects of ensuring stirring time, improving pass rate and quality, and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

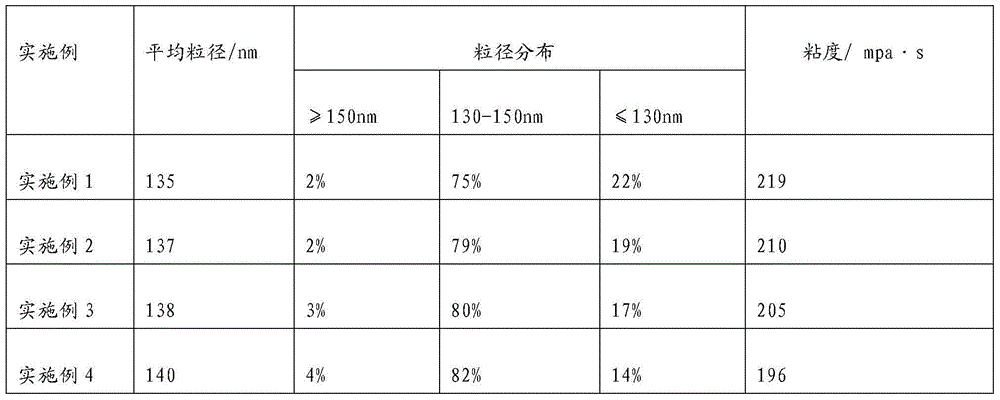

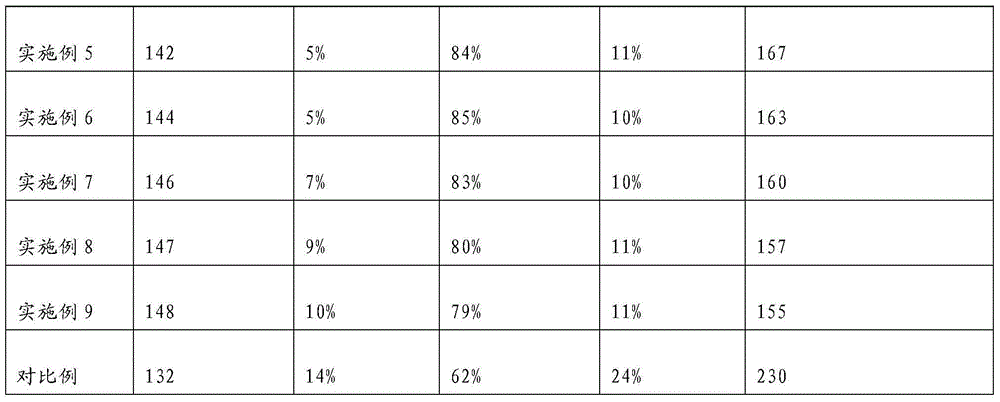

Examples

Embodiment 1

[0027] The present embodiment provides a kind of preparation method of carboxylated styrene-butadiene latex:

[0028] Raw materials: in parts by mass, including: 100 parts of polymerized monomer, 0.5 part of emulsifier, 50 parts of deionized water, 0.3 part of molecular weight regulator and 0.3 part of initiator;

[0029] The composition of the polymerized monomer is: 20wt% of C4 aliphatic conjugated diene, 15wt% of C8 aromatic vinyl compound, 4.5wt% of C3-C5 ethylenically unsaturated carboxylic acid, and C3-C4 unsaturated amide 0.5wt%; the emulsifier includes anionic emulsifier and nonionic emulsifier, the anionic emulsifier is an alkyl sulfate; the nonionic emulsifier is an alkylphenol polyoxyethylene ether; the molecular weight regulator is sulfur Alcohol, described initiator is potassium persulfate aqueous solution;

[0030] The carboxylated styrene-butadiene latex of 20t is produced through the following steps:

[0031] S1: Add a total of 90% deionized water, 25% emulsi...

Embodiment 2

[0038] The present embodiment provides a kind of preparation method of carboxylated styrene-butadiene latex:

[0039] Raw materials: in parts by mass, including: 100 parts of polymerized monomer, 0.6 part of emulsifier, 55 parts of deionized water, 0.4 part of molecular weight regulator and 0.5 part of initiator;

[0040] The composition of the polymerized monomer is: 19wt% of C4 aliphatic conjugated diene, 75wt% of C8 aromatic vinyl compound, 3wt% of C3-C5 ethylenically unsaturated carboxylic acid, 1wt% of C3-C4 unsaturated amide %, C4-C7 acrylate 2wt%; the emulsifier is a mixed emulsifier of anionic emulsifier and nonionic emulsifier, and the anionic emulsifier is an alkyl sulfate; the nonionic emulsifier is an alkylphenol Base polyoxyethylene ether; The molecular weight regulator is a mercaptan, and the initiator is an aqueous solution of ammonium persulfate;

[0041] The carboxylated styrene-butadiene latex of 20t is produced through the following steps:

[0042] S1: Add...

Embodiment 3

[0049] The present embodiment provides a kind of preparation method of carboxylated styrene-butadiene latex:

[0050] Raw materials: in parts by mass, including: 100 parts of polymerized monomer, 0.8 part of emulsifier, 60 parts of deionized water, 0.4 part of molecular weight regulator and 0.7 part of initiator;

[0051] The composition of the polymerized monomer is: 16wt% of C4 aliphatic conjugated diene, 65wt% of C8 aromatic vinyl compound, 1wt% of C3-C5 ethylenically unsaturated carboxylic acid, 3wt% of C3-C4 unsaturated amide %, C4~C7 acrylate 15wt%; said emulsifier includes anionic emulsifier and nonionic emulsifier, said anionic emulsifier is a mixture of alkyl sulfate and alkylbenzene sulfonate; said nonionic emulsifier The agent is a mixture of alkylphenol-based polyoxyethylene ether and polyvinyl alcohol; the molecular weight regulator is mercaptan, and the initiator is a mixed aqueous solution of potassium persulfate and ammonium persulfate;

[0052] The carboxylat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com