Chitin preparation method

A chitin and chitin technology, applied in the field of medicine and chemical industry, can solve the problems affecting the preparation efficiency of chitin, and achieve the effects of improving liquid tightness, good structure compactness and ensuring separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The chitin preparation method of the present invention comprises the following steps: pulverize the chitin raw material, and send the pulverized chitin powder into the reaction kettle; add acid solution to decompose the inorganic salt; the obtained liquid leads to a filter device; dehydrate the filtrate to obtain Chitin. The dehydration of the filtrate is achieved by vacuum distillation.

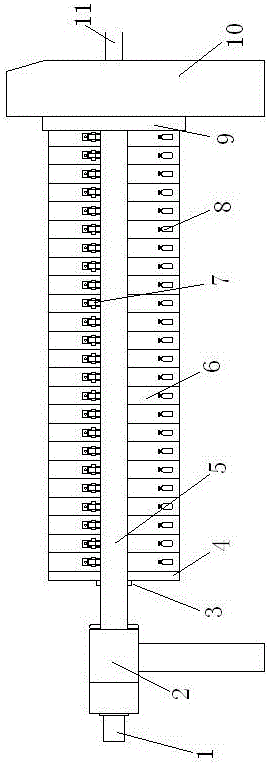

[0027] See figure 1 —4. The chitin preparation method of the present invention is applied to a filter device. The structure of the filter device includes a support and a number of solid-liquid separation units. The support includes a fixed block 2, a liquid guide block 10 and two cross bars 5. These two cross bars 5 The two ends of the cross bar 5 are connected with the fixed block 2 and the liquid guide block 10 respectively.

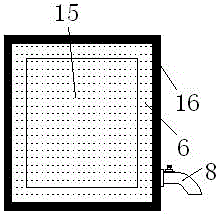

[0028] The main structure of the solid-liquid separation unit is a frame-type filter frame 6, and a protruding handle 7 is provided on opposite sides of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com