Vacuum batch distillation process and device for purifying peach aldehyde from side discharge material

A technology of peach aldehyde and side stream, which is applied in the field of vacuum distillation separation and purification, can solve the problems of unqualified product purity, long operation time, high energy consumption, etc., achieve shortening of rectification process time, shorten rectification time, and improve rectification efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A kind of device that carries out the vacuum space batch rectification process of purifying peach aldehyde by side discharge, as figure 1 As shown, it includes a rectification column tower kettle 2, a condenser 5, a reflux ratio controller 6, a side line discharge tower section 3, a vacuum pump and a collection tank 7, and the outside of the rectification tower is provided with a tower kettle heating jacket 1 and a condenser 5 It is connected to the top of the rectification tower, and the condenser 5 is connected to the rectification tower through a reflux pipeline. The reflux ratio controller 6 is set on the reflux pipeline. The inside of the rectification tower is provided with a packing layer 4, which is filled with high-efficiency separation Packing, high-efficiency separation packing is metal plate corrugated structured packing, wire mesh structured packing, metal mesh corrugated packing, grid packing, pulse packing or high-efficiency random packing. The tower body...

Embodiment 2

[0032] Add 437.3g peach aldehyde reaction crude product in tower still, the peach aldehyde content is 88% in the crude product. The rectification tower is filled with high-efficiency wire mesh structured packing, and the height of the tower is 1.2m.

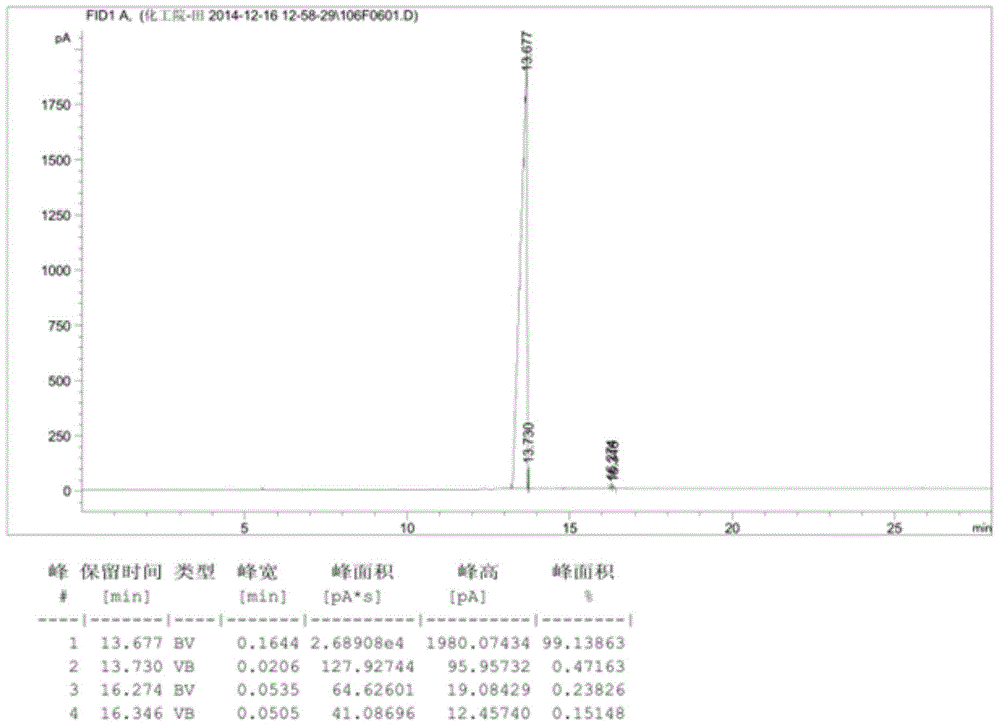

[0033] Start the vacuum pump to evacuate the entire system. The jacket of the tower kettle is heated to 160°C, the tower body is kept at 80°C, and the condensing circulating water at the top of the tower is turned on. When there is reflux at the top of the tower, total reflux for 50 minutes, and the light components are slowly enriched at the top of the tower. When the temperature at the top of the tower is stable at about 92°C, 27g of octanol is extracted at a reflux ratio of 1:1, and then 30g of transition fraction is extracted by adjusting the reflux ratio to 4:1. Continue total reflux for 1 hour, the temperature at the top of the tower is stable at 95°C, and the temperature of the side line is stable at about 134°C. Start t...

Embodiment 3

[0036] Add 477.6g peach aldehyde reaction crude product in tower still, the peach aldehyde content is 88% in the crude product. The rectification tower is filled with high-efficiency wire mesh structured packing, and the height of the tower is 1.5m.

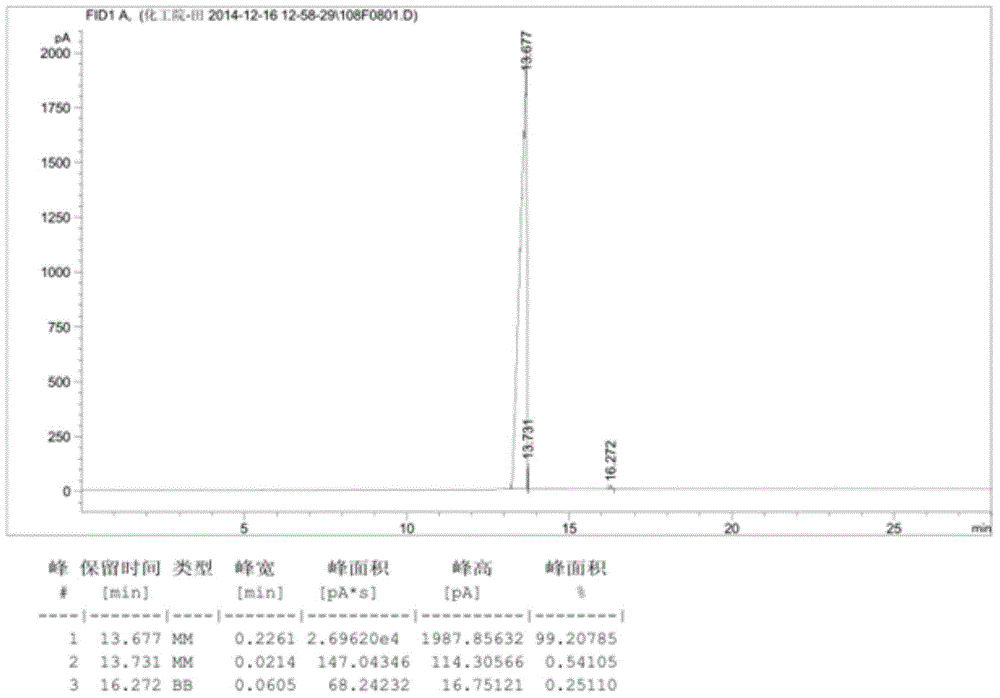

[0037]Start the vacuum pump to evacuate the entire system. The jacket of the tower kettle is heated to 160°C, the tower body is kept at 80°C, and the condensing circulating water at the top of the tower is turned on. When there is reflux at the top of the tower, total reflux for 50 minutes, and the light components are slowly enriched at the top of the tower. When the temperature at the top of the tower is stable at around 90°C, 29g of octanol is extracted at a reflux ratio of 1:1, and then 30g of transition fraction is extracted by adjusting the reflux ratio to 4:1. Continue the total reflux for 1 hour, the temperature at the top of the tower is stable at 93°C, and the temperature of the side line is stable at about 133°C. Sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com