Additive for spraying plastering mortar

A plastering mortar and admixture technology, which is applied in the field of admixtures, dry-mixed mortars and ready-mixed concrete, can solve problems such as unsatisfactory performance, achieve less addition, improve construction efficiency, and excellent performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

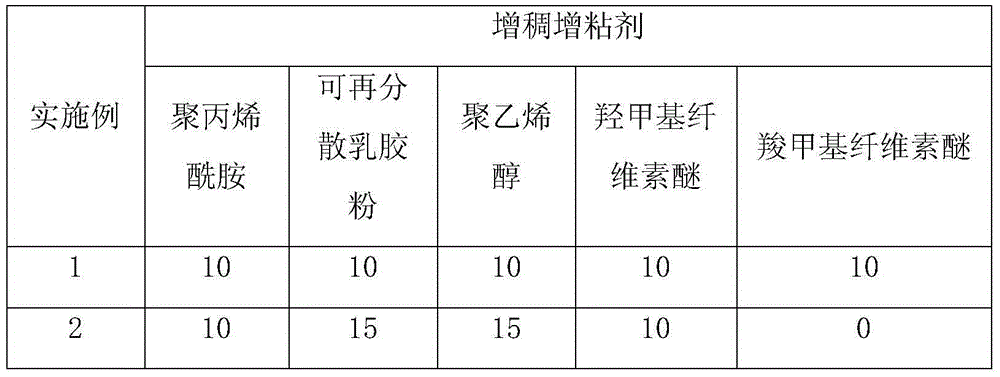

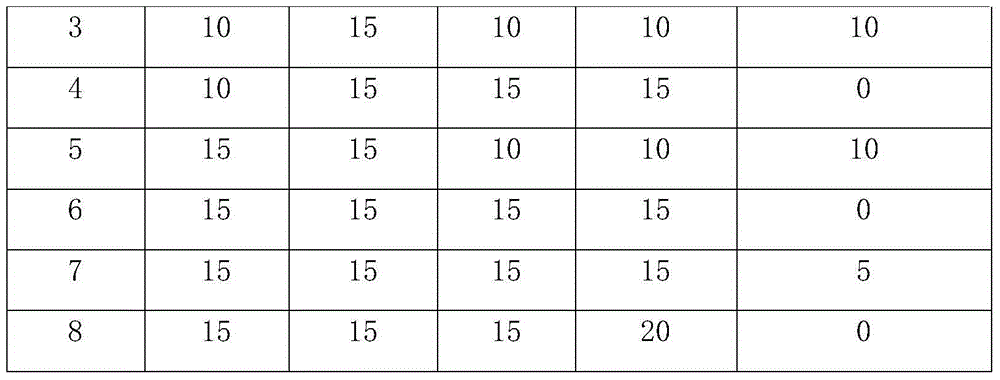

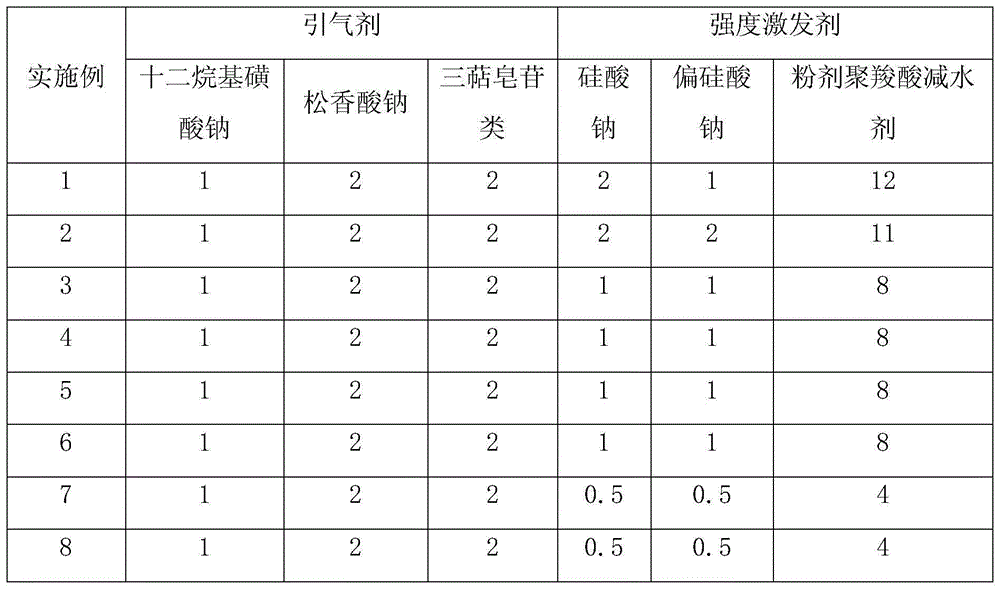

[0021] An admixture for spraying plaster mortar, which consists of the following raw materials in parts by weight:

[0022] Thickening and viscosifying agent, air-entraining agent, strength stimulating agent, coagulation regulator, expansion and anti-cracking agent; the specific ratio of each component is shown in Table 1, 2, 3; The third is mixed.

Embodiment 2

[0024] An admixture for spraying plaster mortar, which consists of the following raw materials in parts by weight:

[0025] Thickening and viscosifying agent, air-entraining agent, strength stimulating agent, coagulation regulator, expansion and anti-cracking agent; the specific proportions of each component are shown in Tables 1, 2, and 3; the usage method is the same as in Example 1.

Embodiment 3

[0027] An admixture for spraying plaster mortar, which consists of the following raw materials in parts by weight:

[0028] Thickening and viscosifying agent, air-entraining agent, strength stimulating agent, coagulation regulator, expansion and anti-cracking agent; the specific proportions of each component are shown in Tables 1, 2, and 3; the usage method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com