A kind of ultrahigh specific surface area hollow carbon nanosphere and its preparation method and application

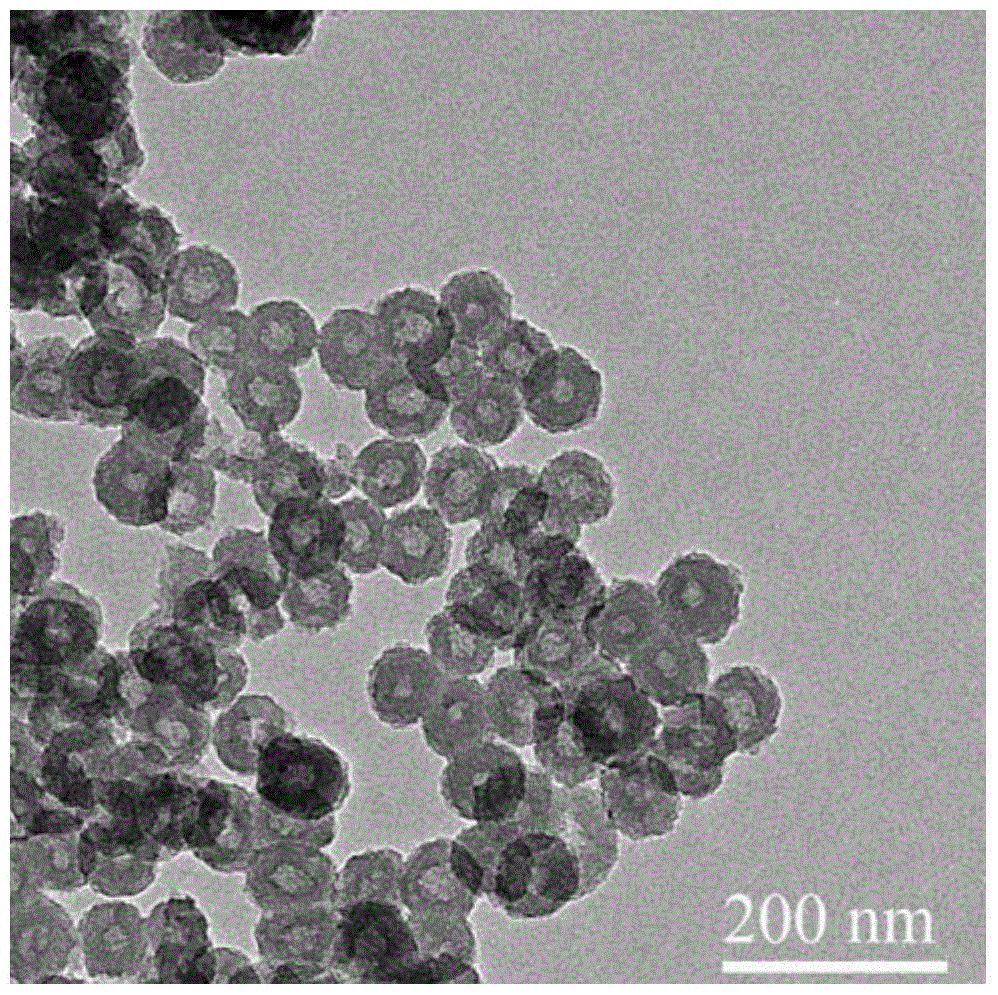

A technology of ultra-high specific surface area, carbon nanospheres, applied in the fields of nanomaterials technology and energy science, can solve the problems of hollow nanometer topography collapse and other problems, achieve large specific surface area and pore volume, uniform and stable size and shape, and good electrical conductivity sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Prepare a hollow carbon nanosphere with an ultra-high specific surface area according to the following steps:

[0035] (1) Dissolve 0.06g Triton X-100 in 60mL water at room temperature, then add 0.29mL pyrrole and 0.38mL aniline in turn, stir magnetically for 0.5h, and disperse ultrasonically for 0.5h; then place in an ice-water bath and stir for 30min; Add an aqueous solution of ammonium persulfate (obtained by dissolving 1.92g of ammonium persulfate in 5mL of water) pre-cooled to 0-5°C, and stir rapidly for 30 seconds with magnetic force; then put it in an ice-water bath for 12 hours, wash the product with water, and Filtrate under reduced pressure until the filtrate is close to neutral, and place the washed product in a vacuum oven at 50°C for 24 hours to obtain a hollow carbon nanosphere precursor;

[0036] (2) Place the hollow carbon nanosphere precursor obtained in step (1) under a nitrogen atmosphere with a flow rate of 400mL / min, raise the temperature to 900°C a...

Embodiment 2

[0041] Prepare a hollow carbon nanosphere with an ultra-high specific surface area according to the following steps:

[0042] (1) According to the step of step (1) in embodiment 1, hollow carbon nanosphere precursor is obtained;

[0043] (2) Place the hollow carbon nanosphere precursor obtained in step (1) under a nitrogen atmosphere at a flow rate of 400 mL / min, raise the temperature to 900 °C at a heating rate of 5 °C / min, carbonize at a constant temperature for 10 h, and cool down naturally to room temperature to obtain The ultra-high specific surface area hollow carbon nanosphere.

[0044] The prepared ultra-high specific surface area hollow carbon nanosphere has an outer diameter of 80 nm and a hollow cavity diameter of 19 nm. BET specific surface area is 2095m 2 / g, where the micropore surface area and the external pore surface area are respectively 1603m 2 / g and 492m 2 / g; the shell pore size distribution is 0.64 and 1.3nm; the total pore volume is 1.56cm 3 / g, wh...

Embodiment 3

[0046] Prepare a hollow carbon nanosphere with an ultra-high specific surface area according to the following steps:

[0047] (1) According to the step of step (1) in embodiment 1, hollow carbon nanosphere precursor is obtained;

[0048] (2) Place the hollow carbon nanosphere precursor obtained in step (1) under a nitrogen atmosphere at a flow rate of 800 mL / min, raise the temperature to 900 °C at a heating rate of 10 °C / min, carbonize at a constant temperature for 10 h, and cool down naturally to room temperature to obtain The ultra-high specific surface area hollow carbon nanosphere.

[0049] The BET specific surface area of the prepared ultra-high specific surface area hollow carbon nanosphere is 2050m 2 / g, where the micropore surface area and external pore surface area are 889m 2 / g and 1161m 2 / g; the shell pore size distribution is 0.68nm, 1.3nm and 2.0nm; the total pore volume is 1.51cm 3 / g, where the micropore volume and external pore volume are 0.39cm 3 / g an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com