Surface treatment device for sand core of housing

A technology of surface treatment device and sand core, which is applied in casting molding equipment, metal processing equipment, manufacturing tools, etc. It can solve the problems of affecting gas flow, affecting the size of inner flow channel, and uneven coating quality, so as to improve the working environment, Improve work efficiency and optimize personnel settings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

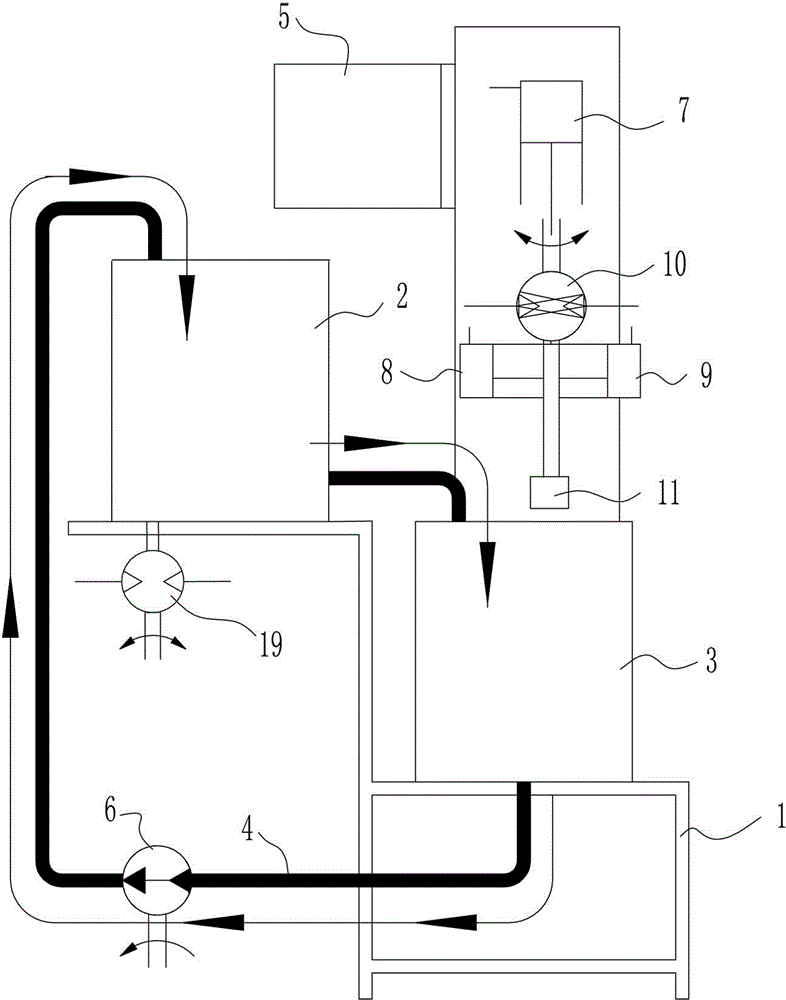

[0025] A preferred embodiment, the driving device includes a first cylinder 7 and a fixed seat 13, the first cylinder 7 is fixed on the bracket 12 on one side of the support seat 1, and the fixed seat 13 is fixed on the lower end of the cylinder rod of the first cylinder 7, During operation, the tooling fixture can be installed on the fixed seat 3, and the PLC control system 5 controls the corresponding solenoid valve of the first cylinder 7 to control the intake and exhaust of the first cylinder 7 and then control the extension length of the cylinder rod of the first cylinder 7 And extend the residence time to control the dip-coating treatment on the surface of the sand core, and the first cylinder of the driving device can also be replaced by a hydraulic cylinder.

[0026] Preferably, the bracket 12 is provided with a guide rail seat 14, and the top of the fixed seat 13 is provided with a guide rail 15 matching with the guide rail seat 14, so that the overall operation of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com