Thermostat for solving function failure of engine control module and control method

A thermostatic device, a technology with functional failure, applied in the direction of engine starting, engine components, machines/engines, etc., can solve problems such as hidden safety hazards, unstable operation of engine modules, and difficulty in starting, and achieve the effect of preventing overheating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

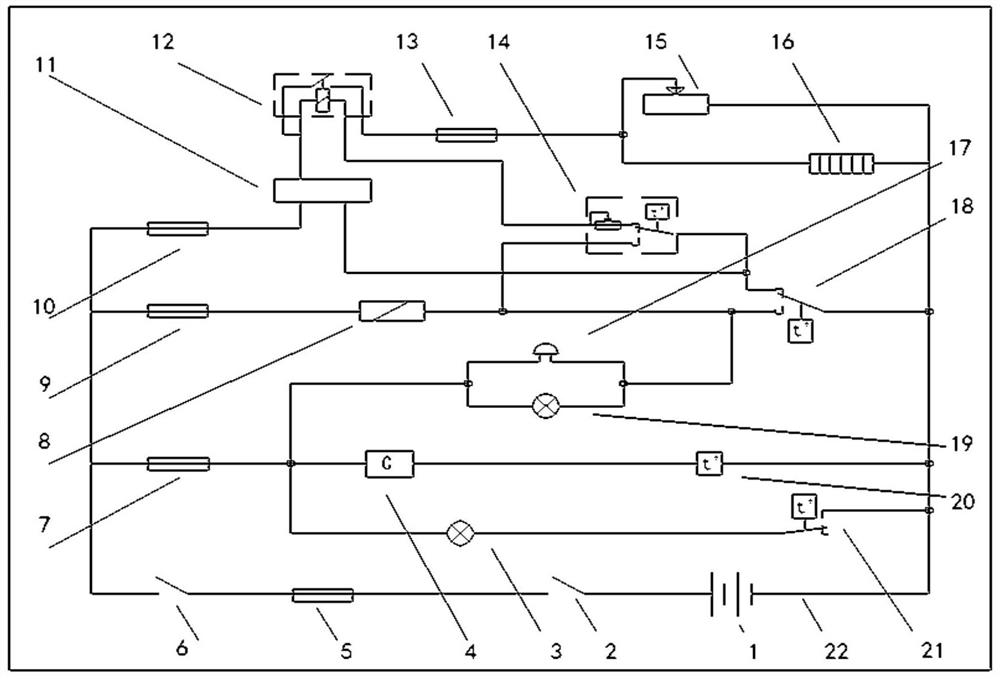

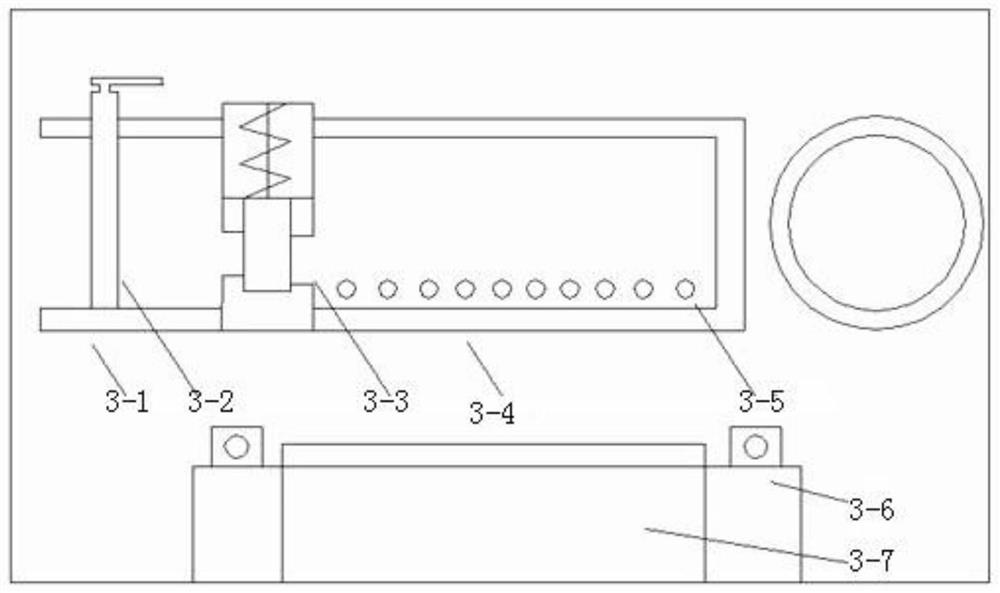

[0043] Example 1: See figure 1 As shown, a constant temperature device of the present invention that solves the functional failure of the engine control module includes functional systems such as a temperature speed control system, an electronically controlled heating system, a high-temperature automatic cooling system, and temperature monitoring and protection. , high-temperature automatic heat dissipation and temperature monitoring protection and other functional systems are connected in parallel with the battery pack 1, the main power switch 2, the electric control lock fuse 4, and the electric control lock 6 to form a closed-loop control loop; the line 22 has a conductive medium inside; The temperature speed regulating system includes a temperature speed regulating fuse 11, a temperature speed regulating resistor 15, and a heating element 16 sequentially connected in series through lines to form a control loop; the high temperature automatic heat dissipation system includes...

Embodiment 2

[0044] Embodiment 2: In cold weather, after the vehicle (frame car) stops temporarily for about half an hour, the engine module of the frame car is affected by the ambient temperature and the temperature drops. Open the electric control lock, and the temperature sensor will display the detected temperature of the engine module casing on the display; when the temperature of the engine module casing is lower than the low temperature alarm value, the temperature switch (low temperature) will control the low temperature warning light to flash to remind the driver to wait The electronically controlled heating system works; at this time, the electronically controlled heating system is in closed-loop control, the heating temperature is controlled by the temperature adjustment switch, the time relay starts to count down the heating, and the heating element heats up the engine module shell until the temperature of the engine module shell reaches the temperature adjustment switch When th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com