Device for controlling and collecting aluminum and magnesium powder generated by polishing, grinding and wiredrawing on platform

A technology for collecting device and dust, applied in grinding/polishing safety device, machine tool with surface polishing, grinding/polishing equipment, etc., can solve the problems of inability to remove dust and collection of fine particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

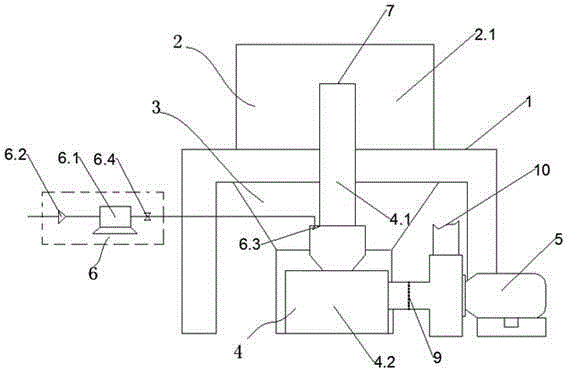

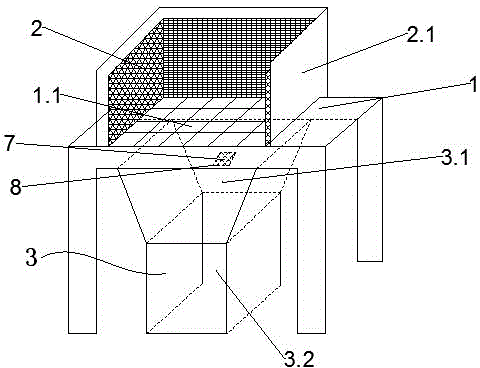

[0015] like figure 1 , shown in 2, a polishing, grinding, wire drawing platform aluminum magnesium dust control and collection device, including a working platform 1, a fine mesh filter screen baffle 2, a large particle collection device 3, a fine particle collection device 4, a fan 5, a low pressure Water mist device6.

[0016] The table top of the working platform 1 is composed of a large-aperture grid 1.1; the fine mesh filter baffle baffle 2 is distributed on three sides of the working platform 1; the large particle collection device 3 is located under the middle area of the working platform 1 to collect, polish and polish Or large particles produced during the drawing process. The fine grid filter screen baffle 2 is connected with the ventilation duct 4.1, and the ventilation device can collect the fine dust to the fine particle collection devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com