Veterinary enrofloxacin injection and preparation method thereof

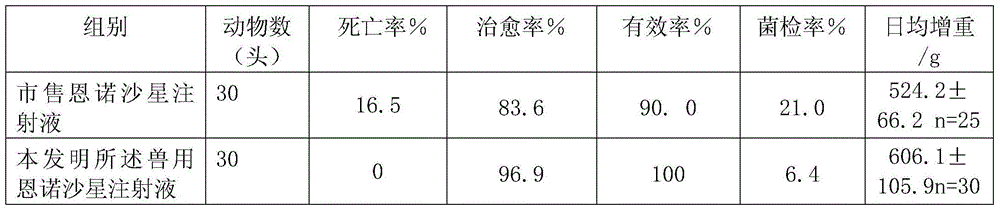

A technology of enrofloxacin and injection, applied in the field of veterinary drug preparation, can solve the problems of poor stability, low cure rate, short duration of drug effect, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Take 1% of polyvinylpyrrolidone, 1.5% of benzyl alcohol, 40% of propylene glycol and appropriate amount of water for injection according to the aforementioned weight percentages and add them to the concentrated mixing tank, and heat to 60°C with steam;

[0031] (2) Dissolve 0.1% of anhydrous sodium sulfite and 0.01% of EDTA-2Na with an appropriate amount of water for injection, and add them to the concentrated mixing tank under stirring;

[0032] (3), add enrofloxacin 2.5% of the aforementioned weight percentage, L-arginine base 10%, stir to dissolve;

[0033] (4), adjust the pH value to 9.5-10.5 with 10% sodium hydroxide aqueous solution, filter to dilute the tank, add water for injection to the full amount;

[0034] (5) The intermediate is qualified, finely filtered, filled with nitrogen and sealed, then steam sterilized at 115°C for 30 minutes, cooled to room temperature, packed, and put into storage for inspection.

Embodiment 2

[0036] (1) Take 1.5% of polyvinylpyrrolidone, 3% of benzyl alcohol, 35% of propylene glycol and appropriate amount of water for injection according to the aforementioned weight percentages and add them to the concentrated mixing tank, and heat to 60°C with steam;

[0037] (2) Dissolve 0.15% of anhydrous sodium sulfite and 0.015% of EDTA-2Na with an appropriate amount of water for injection, and add them to the concentrated preparation tank under stirring;

[0038] (3), add enrofloxacin 5%, L-arginine alkali 15% of aforementioned weight percentage, stir to dissolve;

[0039] (4), adjust the pH value to 9.5-10.5 with 15% sodium hydroxide aqueous solution, filter to dilute the tank, add water for injection to the full amount;

[0040] (5) The intermediate is qualified, finely filtered, filled with nitrogen and sealed, then steam sterilized at 115°C for 30 minutes, cooled to room temperature, packed, and put into storage for inspection.

Embodiment 3

[0042] (1) Take 1.8% of polyvinylpyrrolidone, 5% of benzyl alcohol, 30% of propylene glycol and appropriate amount of water for injection according to the aforementioned weight percentages and add them to the concentrated mixing tank, and heat to 60°C with steam;

[0043] (2) Dissolve 0.18% of anhydrous sodium sulfite and 0.018% of EDTA-2Na with an appropriate amount of water for injection, and add them to the concentrated preparation tank under stirring;

[0044] (3), add the enrofloxacin 10% of aforementioned weight percentage, L-arginine base 20%, stir to dissolve;

[0045] (4), adjust the pH value to 9.5-10.5 with 20% sodium hydroxide aqueous solution, filter to dilute the tank, add water for injection to the full amount;

[0046] (5) The intermediate is qualified, finely filtered, filled with nitrogen and sealed, then steam sterilized at 115°C for 30 minutes, cooled to room temperature, packed, and put into storage for inspection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com