Printed curcuit board and manufacturing method of the same

A technology for printed circuit boards and circuit layers, which is applied in the fields of printed circuit manufacturing, printed circuits, printed circuits, etc., can solve the problems of limited integrated circuit graphics, prevent warping or distortion, reduce preparation costs, and increase integration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0116]A method for preparing a printed circuit board according to an embodiment of the present invention includes: providing a composite material layer having one side and another side, forming a first circuit layer on one side of the composite material layer, and forming a first circuit layer on the composite material layer, respectively. The step of forming a second circuit layer on the other side of the layer, and forming a third circuit layer on the first circuit layer, forming a first insulating layer between the first circuit layer and the third circuit layer , forming a fourth circuit layer on the second circuit layer, and forming a second insulating layer between the second circuit layer and the fourth circuit layer.

[0117] Here, the filler content of the first insulating layer and the filler content of the second insulating layer are formed to be different from each other, and when the remaining copper ratio of the first insulating layer is higher than that of the se...

experiment example

[0137] In this experimental example, in order to observe the warpage occurrence characteristic due to the thermal expansion coefficient of the composite material layer which is a polymer material used in a printed circuit board, the warpage phenomenon was observed while adjusting the amount of the filler.

[0138] First of all, for the composition of the printed circuit board, in order to avoid repeated descriptions, cite figure 1 and figure 2 .

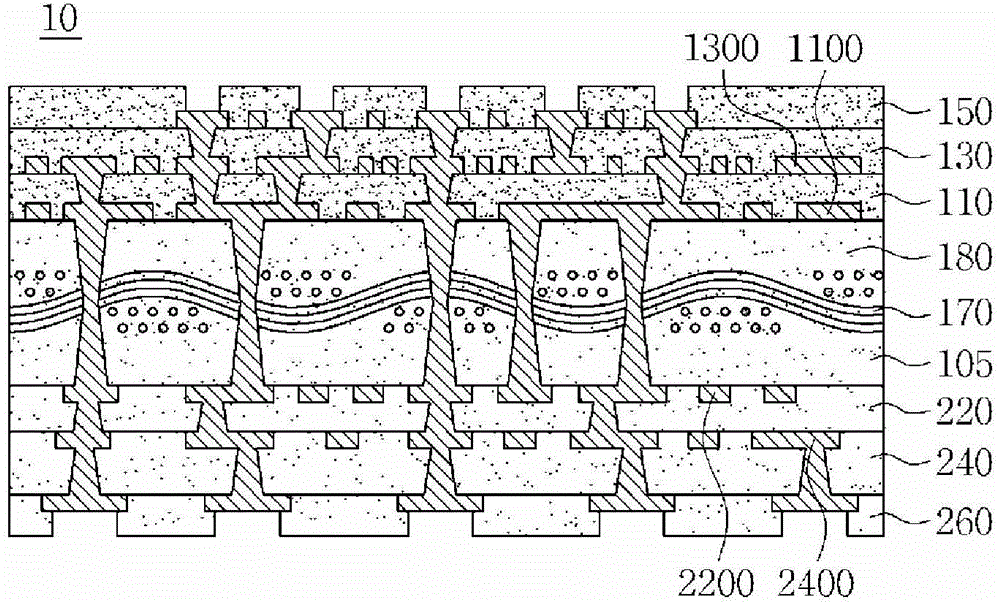

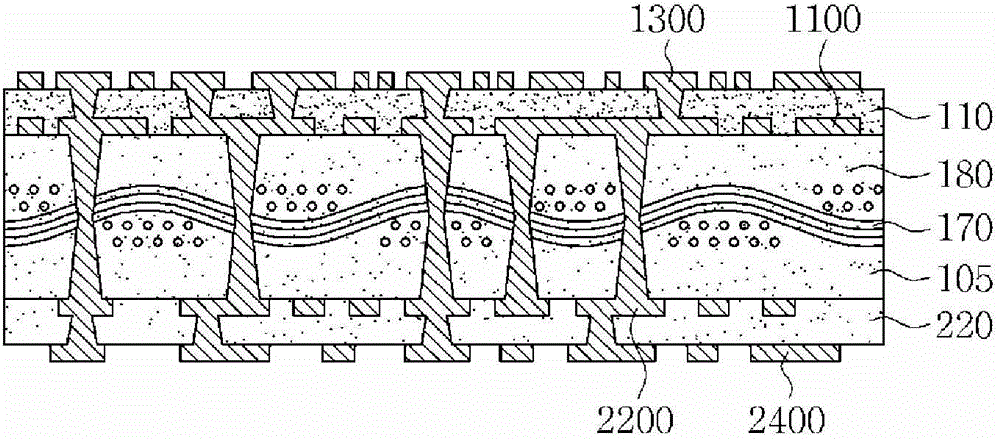

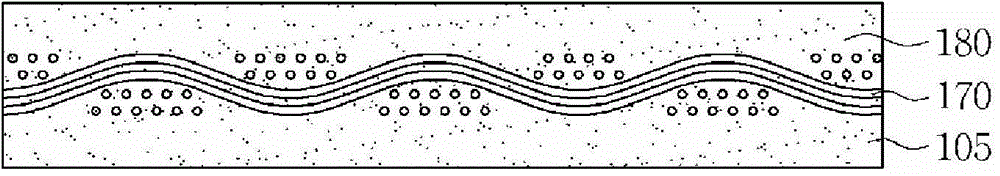

[0139] A composite material layer 105 is formed in the middle of the printed circuit board 10 . Here, the composite material layer 105 is used to increase the modulus of the printed circuit board 10 and is a prepreg containing glass fibers. Such a composite material layer 105 may be a single layer or multiple layers. In addition, circuit layers are formed on both sides of the composite material layer 105, and insulating layers are formed on the circuit layers. In this way, circuit layers and insulating layers are laminated in an...

Embodiment 1

[0149]In Example 1, different from the comparative example, according to the residual copper ratio formed on the composite material layer and the insulating layer, that is, the volume and area of copper, the amount of the filler mixed in the composite material layer and the insulating layer was adjusted and carried out. Add to.

[0150] As shown in Table 1, the residual copper rate of the first circuit layer is 39.8%, and the residual copper rate of the third circuit layer is 43.4%. The first insulating layer existing between the first circuit layer and the third circuit layer The residual copper rate is 83.2%. In addition, the residual copper rate of the second circuit layer was 53.0%, the residual copper rate of the fourth circuit layer was 46.9%, and the residual copper rate of the second insulating layer existing between the second circuit layer and the fourth circuit layer was Formation is 99.9%.

[0151] Here, the filler content was reduced by 20% in the first insula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com