Anode material for lithium-ion battery and preparation method of anode material

A technology of lithium-ion batteries and negative electrode materials, applied in battery electrodes, nanotechnology for materials and surface science, circuits, etc., can solve problems such as poor rate performance, poor structural stability, unsuitable preparation process, etc. Low cost, sufficient raw materials, good ion/electronic conduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

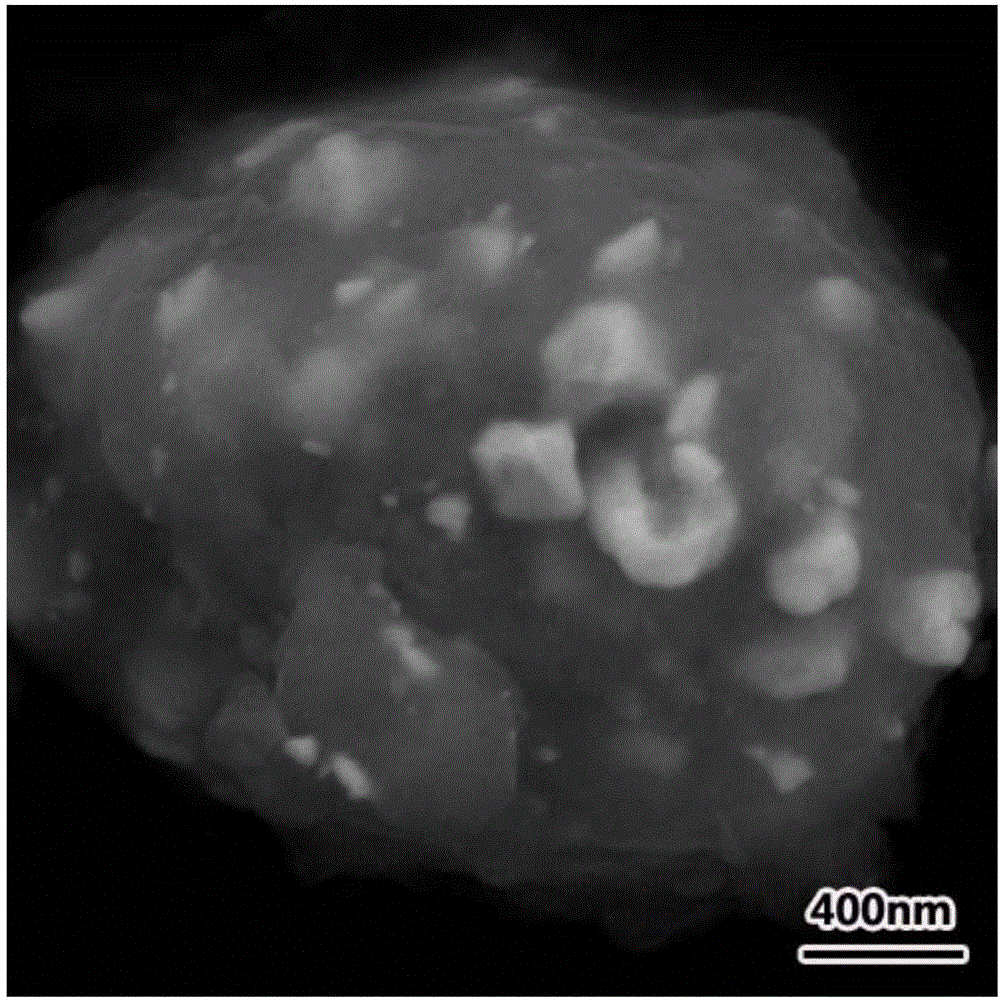

Image

Examples

Embodiment 1

[0039] The WC powder with a purity of 99.9%, a particle size of 325 mesh, a purity of 99.9%, and a particle size of 1 to 2 microns is ball milled in the first step under the protection of argon; 60% of the total mass of the Si-WC composite powder; the rotational speed of the ball mill was 1000 rpm, the ball milling time was 25 hours, and the mass ratio of the stainless steel ball to the powder was 60:1 to obtain the Si-WC composite powder.

[0040] The above-mentioned Si-WC composite powder obtained through ball milling, and the graphite powder with a purity of 99.9% and a particle size of 30 to 40 microns are subjected to the second ball milling under the protection of argon; 50% of the total mass of the powder, the rotational speed of the ball mill was 1000 rpm, the ball milling time was 10 hours, and the mass ratio of the stainless steel ball to the powder was 60:1 to obtain the Si-WCG composite material.

[0041] The prepared Si-WCG composite material was uniformly mixed w...

Embodiment 2

[0043] The WC powder with a purity of 99.9%, a particle size of 325 mesh, a purity of 99.9%, and a particle size of 1 to 2 microns is ball milled in the first step under the protection of argon; 50% of the total mass of the powder; the rotational speed of the ball mill was 1000 rpm, the ball milling time was 25 hours, and the mass ratio of the stainless steel ball to the powder was 60:1 to obtain the Si-WC composite powder.

[0044]The above-mentioned Si-WC composite powder obtained through ball milling, and the graphite powder with a purity of 99.9% and a particle size of 30 to 40 microns are subjected to the second ball milling under the protection of argon; the mass of the graphite powder accounts for 50% of the total mass of the powder, the rotational speed of the ball mill was 1000 rpm, the ball milling time was 10 hours, and the mass ratio of the stainless steel ball to the powder was 60:1 to obtain the Si-WCG composite material.

[0045] The prepared Si-WCG composite ma...

Embodiment 3

[0047] The WC powder with a purity of 99.9%, a particle size of 325 mesh, a purity of 99.9%, and a particle size of 1 to 2 microns is ball milled in the first step under the protection of argon; 40% of the total mass of the Si-WC composite powder; the rotational speed of the ball mill was 1000 rpm, the ball milling time was 25 hours, and the mass ratio of the stainless steel ball to the powder was 50:1 to obtain the Si-WC composite powder.

[0048] The above-mentioned Si-WC composite powder obtained through ball milling, and the graphite powder with a purity of 99.9% and a particle size of 30 to 40 microns are subjected to the second ball milling under the protection of argon; the mass of the graphite powder accounts for 50% of the total mass of the powder, the rotational speed of the ball mill was 1000 rpm, the ball milling time was 10 hours, and the mass ratio of the stainless steel balls to the powder was 50:1 to obtain the Si-WCG composite material.

[0049] The prepared S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com