Rapid testing paper for testing hydrogen peroxide residue in foods

A technology for hydrogen peroxide and test paper detection, which is applied in the direction of analyzing materials through chemical reactions and observing the influence of chemical indicators on materials, etc. Long response time and other issues, to achieve the effects of shortened production cycle, low production cost, simple structure and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

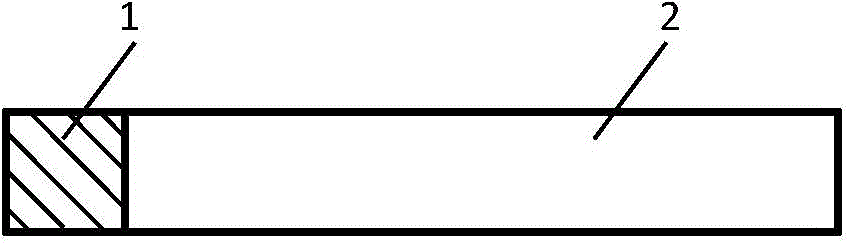

[0030] First configure reaction solution A and reaction solution B, the solvent in reaction solution A is citric acid buffer solution with a pH value of 5.0, the solute is 0.4g / L horseradish peroxidase (HRP) and 5g / L polyvinylpyrrolidone The solvent in reaction solution B is absolute ethanol, and the solute is a mixture of 1.0g / L 3,3',5,5'-tetramethylbenzidine and 1mL S20 (TWEEN80). Soak 3mm chromatographic filter paper in the reaction solution A for 10s, dry it for 45min at a vacuum degree of 100Pa and a temperature of 45°C, then soak it in the reaction solution B for 10s, and dry it at a temperature of 50°C and a vacuum degree of 100Pa. Dry for 25 minutes. Adhere the treated filter paper on the substrate and cut it into 0.55cm×7cm test strips. Sealed and stored in a dry environment at 4°C, and should not be exposed to direct sunlight.

Embodiment 2

[0032] First configure reaction solution A and reaction solution B. The solvent in reaction solution A is citric acid buffer solution with a pH value of 5.0, the solute is 0.6g / L horseradish peroxidase (HRP) and 10g / L polyvinylpyrrolidone The solvent in reaction solution B is absolute ethanol, and the solute is a mixture of 2.0g / L 3,3',5,5'-tetramethylbenzidine and 3mL S20 (TWEEN80). Soak 3mm chromatographic filter paper in the reaction solution A for 20s, dry it for 50min at a vacuum degree of 110Pa and a temperature of 50°C, then soak it in the reaction solution B for 20s, and dry it at a temperature of 50°C and a vacuum degree of 110Pa. Dry for 30min. Adhere the treated filter paper on the substrate and cut it into 0.55cm×7cm test strips. Sealed and stored in a dry environment at 4°C, and should not be exposed to direct sunlight.

Embodiment 3

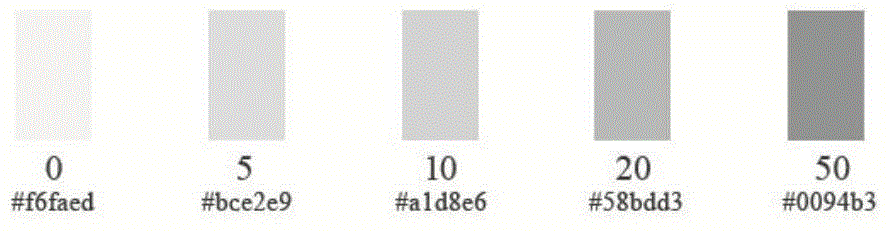

[0035]Take 20 samples of well-known brand milk purchased from supermarkets, take appropriate amount of samples in a clean dry container, take the area of the chromogenic film immersed in the test paper as the standard, take it out immediately after immersion, and place the chromogenic film horizontally with the chromogenic film facing up. Semi-quantitative readings were then performed. Compare the color of the test paper with the standard color chart, and the value corresponding to the same color scale as the color scale of the color chart is the detection value of the sample. If the color of the test paper is between the two color scales, take the middle value of the two . The residual amount of hydrogen peroxide in the 20 milk samples was measured to be 0 mg / L, which was a qualified sample.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com