Loading force direction self-balanced loading device and force direction self-controlled numerical control knife rest static rigidity test platform

A technology of loading device and test platform, which is applied in the testing of mechanical components, testing of machine/structural components, measuring devices, etc., can solve the problem of force loading direction deviation, difficult to control the position of force loading point, and tool holder static stiffness test process. Insufficient specification and other problems to achieve the effect of ensuring verticality, preventing offset and change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

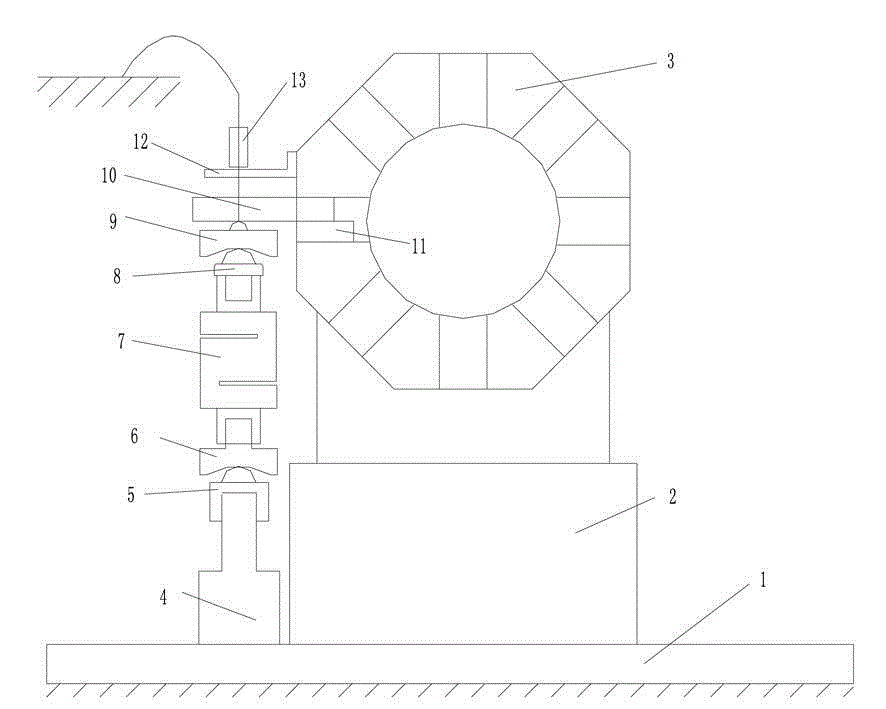

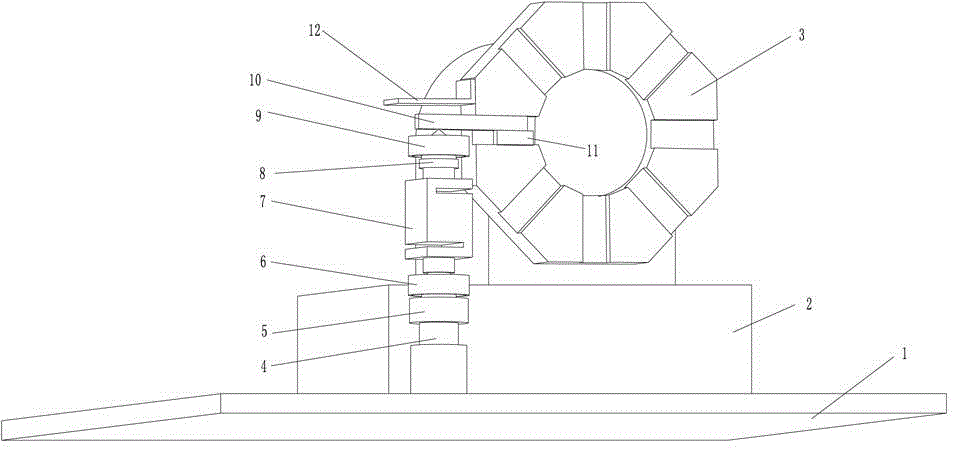

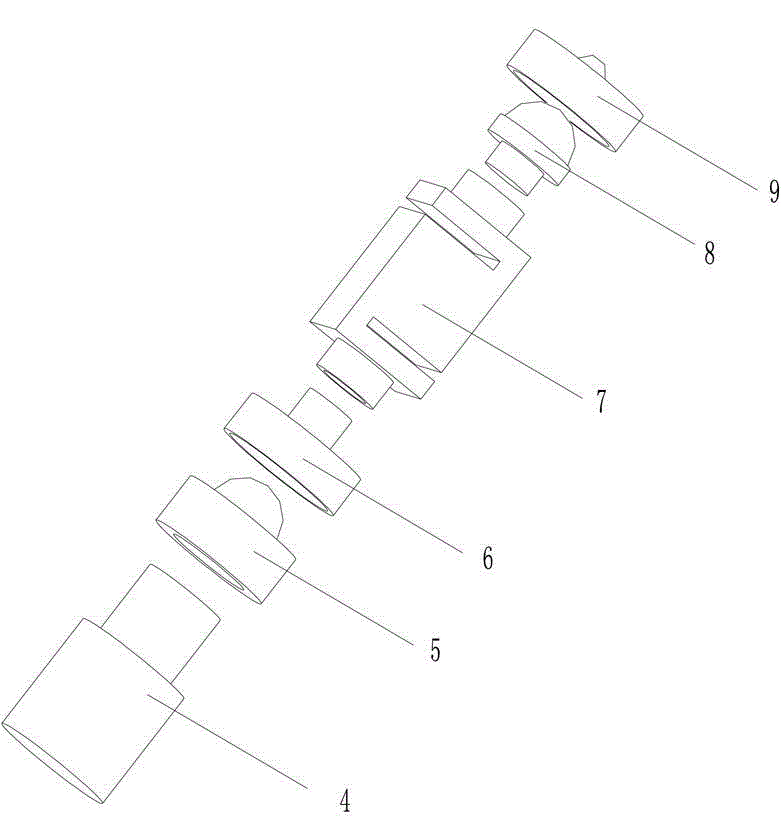

[0037] The static stiffness testing device of the tool holder of the present embodiment to ensure that the load force is applied to the point and direction is as follows: figure 1 with figure 2 As shown, the CNC tool post 3 is fixed on the rigid tool post fixed chassis 2, and the tool post fixed chassis 2 is fixedly connected to the test bench 1 through a clamp. The knife bar 9 is clamped and fixed on a certain station on the numerically controlled tool rest 3 by the knife pressing block 11 . Due to the problem that it is easy to slip when directly collecting the displacement of the measuring point of the cutter head of the tool holder, a cutter head receiving plate 12 is designed and installed on the cutter head by screws or other methods as a displacement test point. The eddy current sensor probe 13 in the displacement testing device is fixed by the universal magnetic gauge base, and the reference of the magnetic base is the ground.

[0038] The jack 4 is fixed on the te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com