Three-dimensional target and global unified calibration method for linear structured light profile sensor

A line-structured light and sensor technology, applied in the direction of instruments, optical devices, measuring devices, etc., can solve the problems of high cost, difficult processing of three-dimensional targets, and difficulty in achieving the expected accuracy, and achieve the effect of reducing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, but the implementation scope of the present invention is not limited thereto.

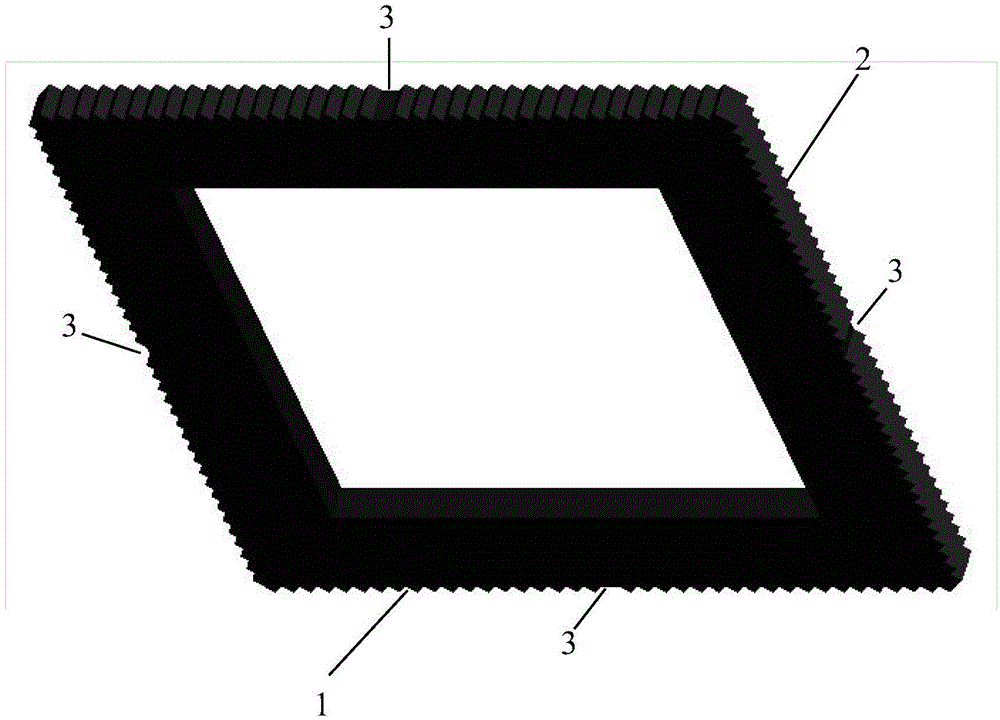

[0031] Such as figure 1 Shown is a schematic diagram of the sawtooth three-dimensional target model designed in the present invention.

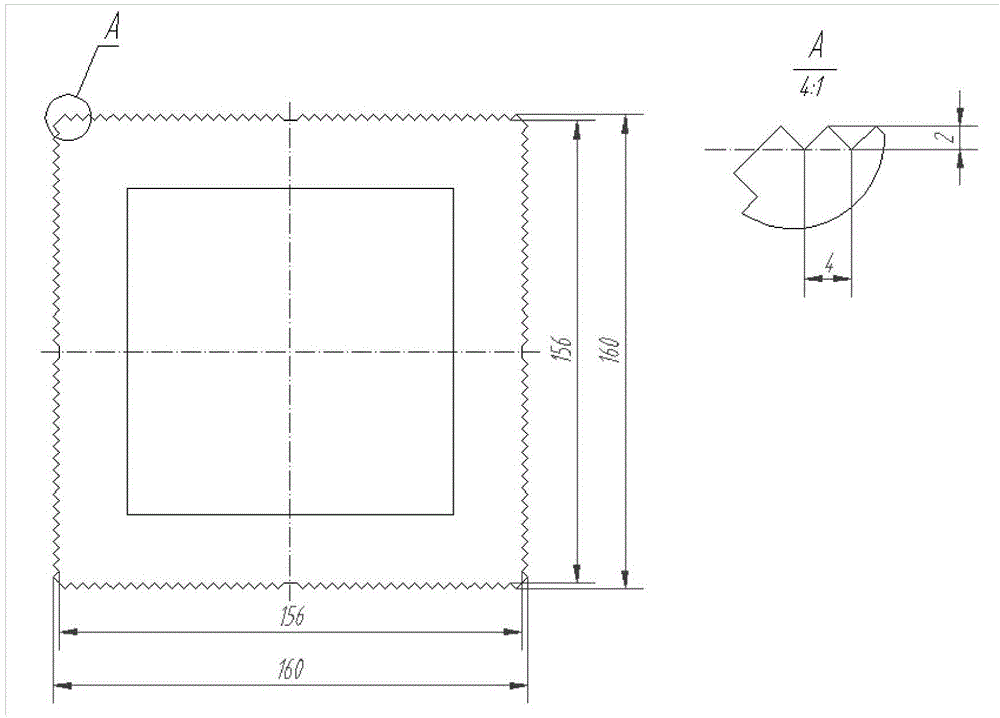

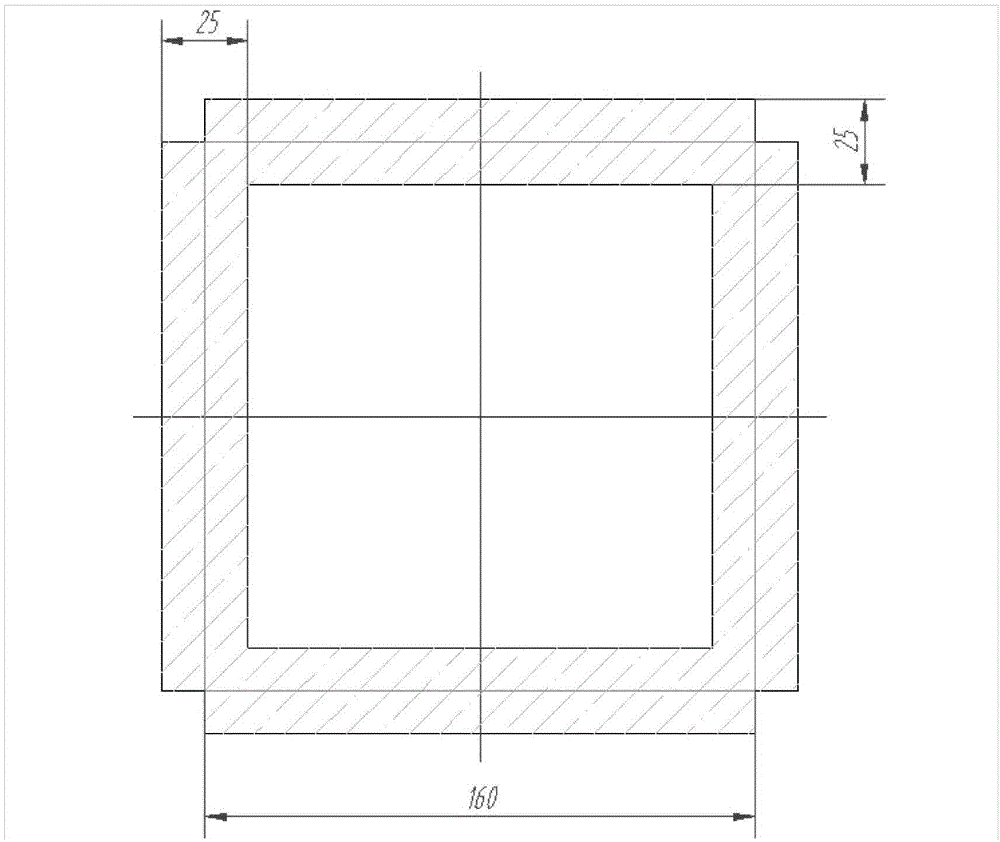

[0032] Such as figure 2 Shown is a schematic diagram of the cross-sectional structure of the target.

[0033] 1. Three-dimensional target

[0034] The three-dimensional target of the present invention is in the shape of a three-dimensional square ring, and each of the four sides of the target has 38 uniform sawtooth-shaped grooves, which are symmetrically distributed along the side length of the square; at the same time, when the target is processed, the center of each side of the square There will be a missing tooth in the position, and its purpose is to determine the virtual origin and facilitate the deduction of the topologi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com