A heat pump tail heat recovery microwave oxygen insulation dryer

A tail heat recovery, heat pump technology, applied in progressive dryers, dryers, drying gas layout, etc., can solve the problems of difficult heat transfer and penetration, unable to meet lily, difficult to industrial production, etc., to maintain uniform quality , reduce costs and energy consumption, and improve the effect of drying quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

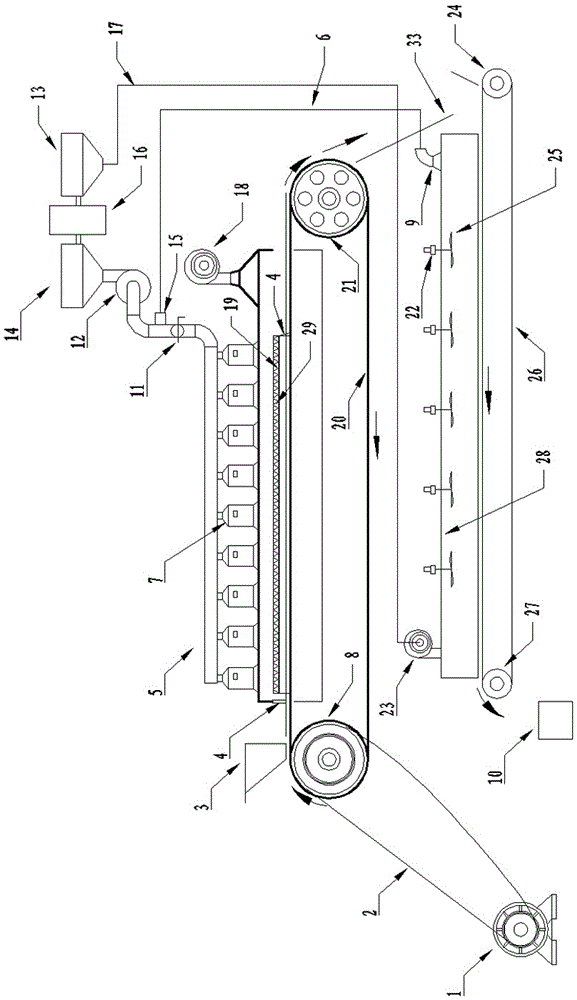

[0027] Now in conjunction with accompanying drawing, the present invention is described in further detail.

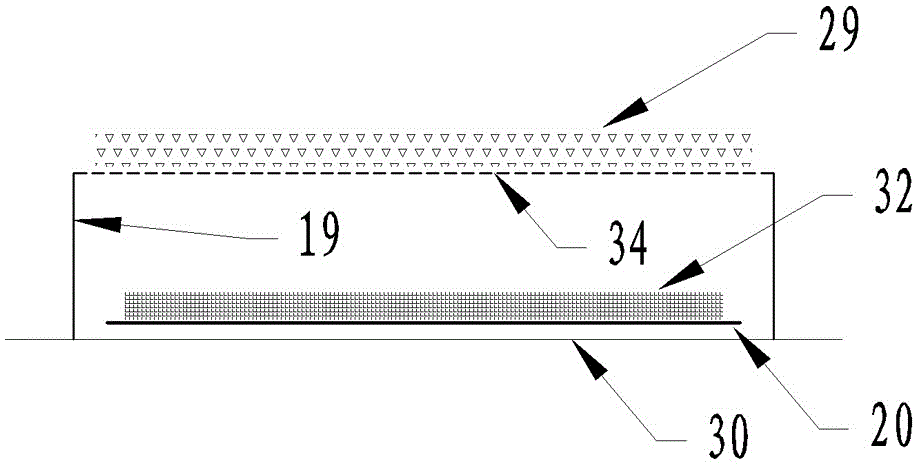

[0028] Such as figure 1 and figure 2 The shown heat pump tail heat recovery microwave oxygen insulation dryer includes a conveyor belt 20, a microwave unit 7 and a glass cover 19, the glass cover 19 is tunnel-shaped and fixed on the substrate 30 below the conveyor belt 20, and the tunnel-shaped glass cover 19 is The plate is provided with air-permeable sieve holes 34 and covered with a certain thickness of glass packing ring 29. A microwave unit 7 is arranged above the glass packing ring. The plate 33 arrives on the conveyor belt 26 of the isolation box 28; the exit of the tunnel-shaped glass cover 19 is provided with a barrier curtain 4 and a blower 18, and the entrance is provided with a barrier curtain 4; the exhaust pipe 5 communicates with the microwave unit above the breathable mesh 34 7. The microwave unit 7 acts as a gas collection box. The exhaust pipe 5 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com