Electromagnetic heating device

A heating device, electromagnetic technology, applied in the direction of the coil device, electric heating system, heating method, etc., can solve the problems of PTC honeycomb heating device is easy to break, heat dissipation corrugated aluminum metal is easy to rust, thermal efficiency decline, etc., to achieve good heat dissipation, no Risk of electric shock, long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

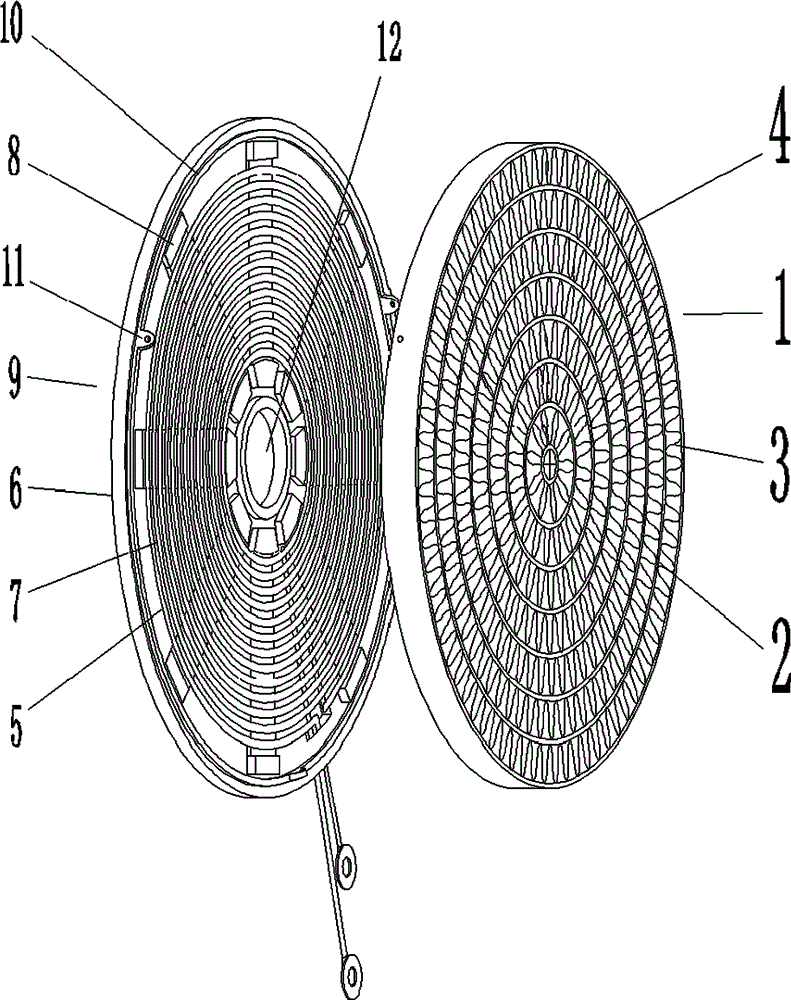

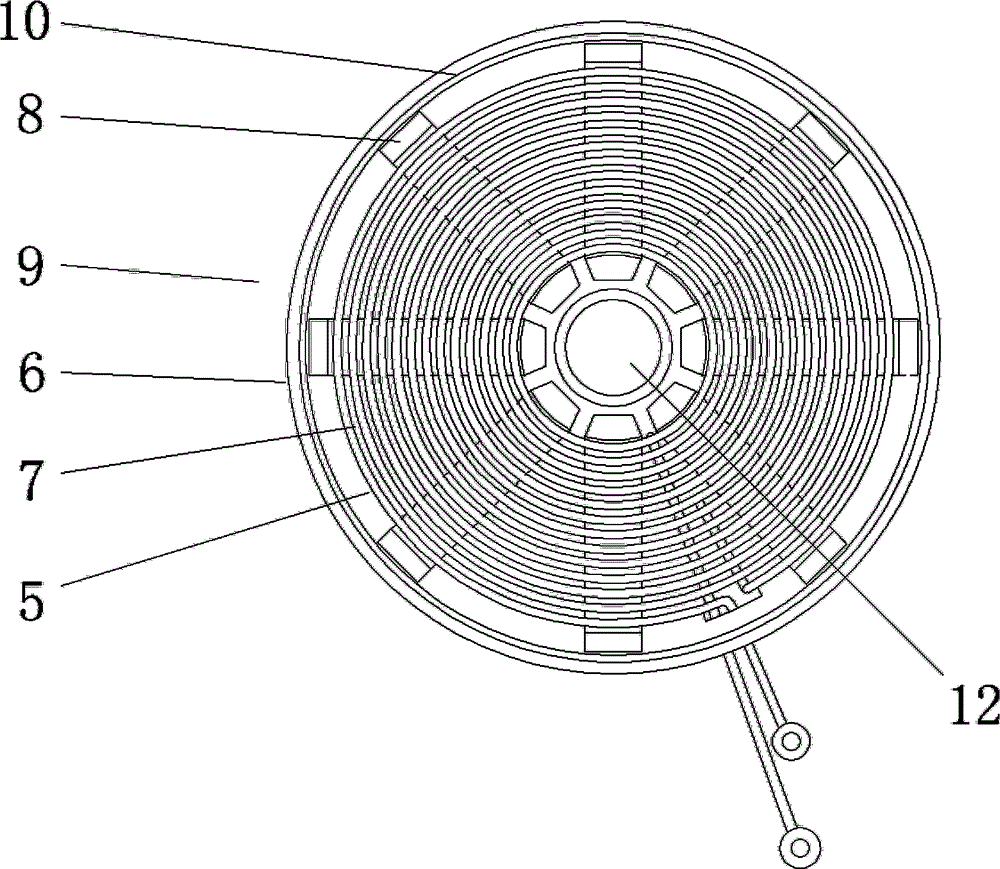

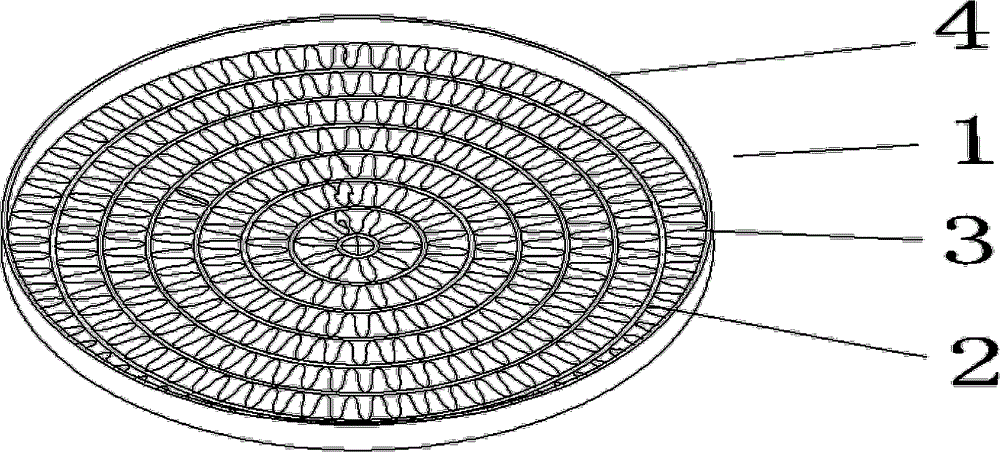

[0020] exist figure 1 , figure 2 , image 3 Among them, the coil (5) installed on the coil (9) is a loose winding structure, and there is a gap (7) between the coils for ventilation. There is a raised wall (10), and the center of the support (6) of the wire reel (9) is a through hole (12) for installing a temperature sensor. On the other side of the wire reel (9), the support (6) is equipped with Eight magnetic strips (8) are used for magnetic conduction to improve efficiency. The honeycomb heating element (1) is installed in the direction of the coil (5) of the coil (9). The corrugated rings (3) of the shaft alternately form a mixed ferrule honeycomb structure, that is, the corrugated rings are surrounded by flat rings, and the flat rings are surrounded by corrugated rings, and so on. The axial width (or the length of the ring) of the outer ring (4) is larger than the thickness of the inner honeycomb disk, and the left side of the outer ring (4) protrudes from the honeyc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com